BubsBuilds Projects

- Details

- Parent Category: Just Playin and Concept Demo Projects

- Category: Flexure Fun

Build

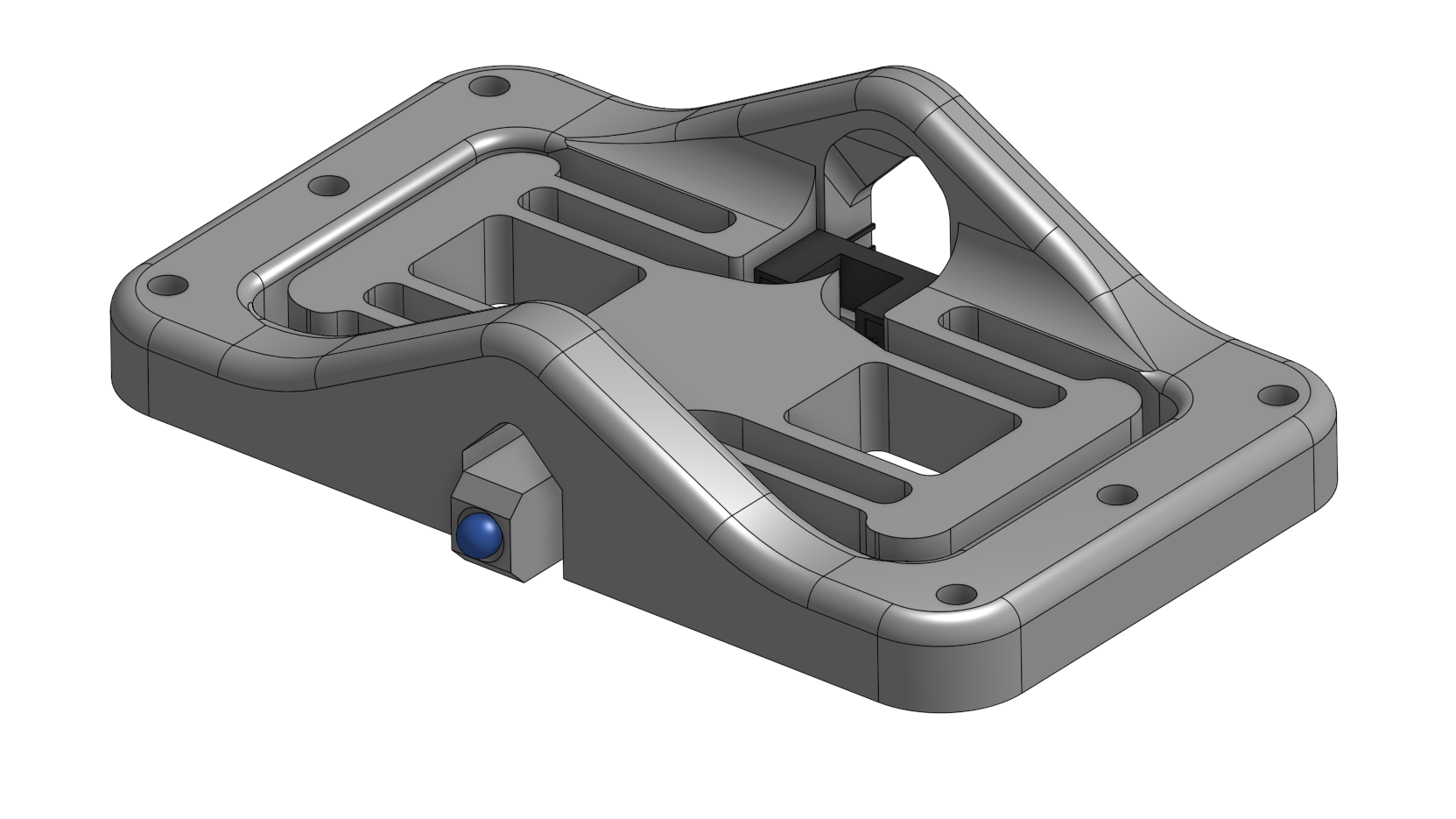

- Printed Parts:

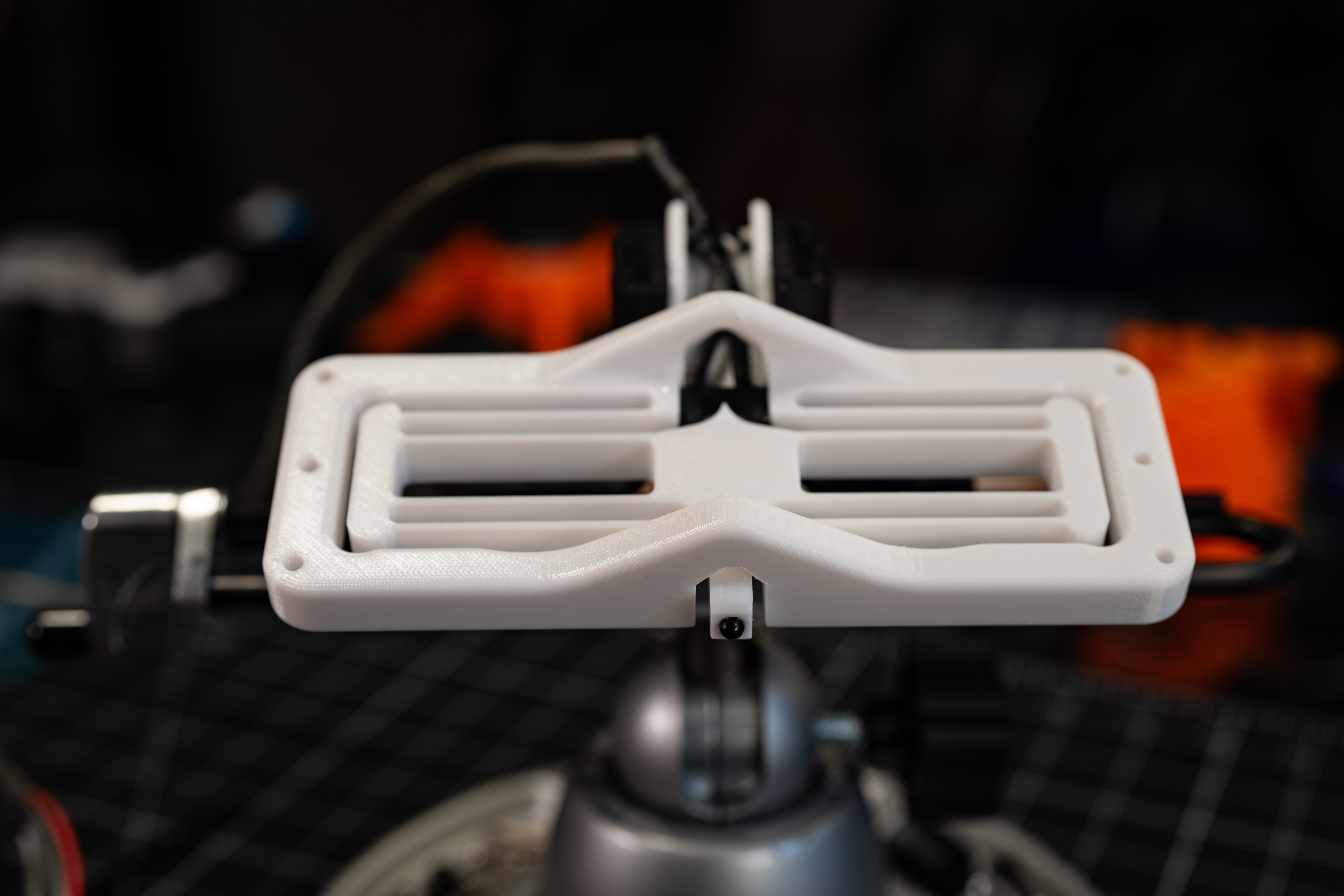

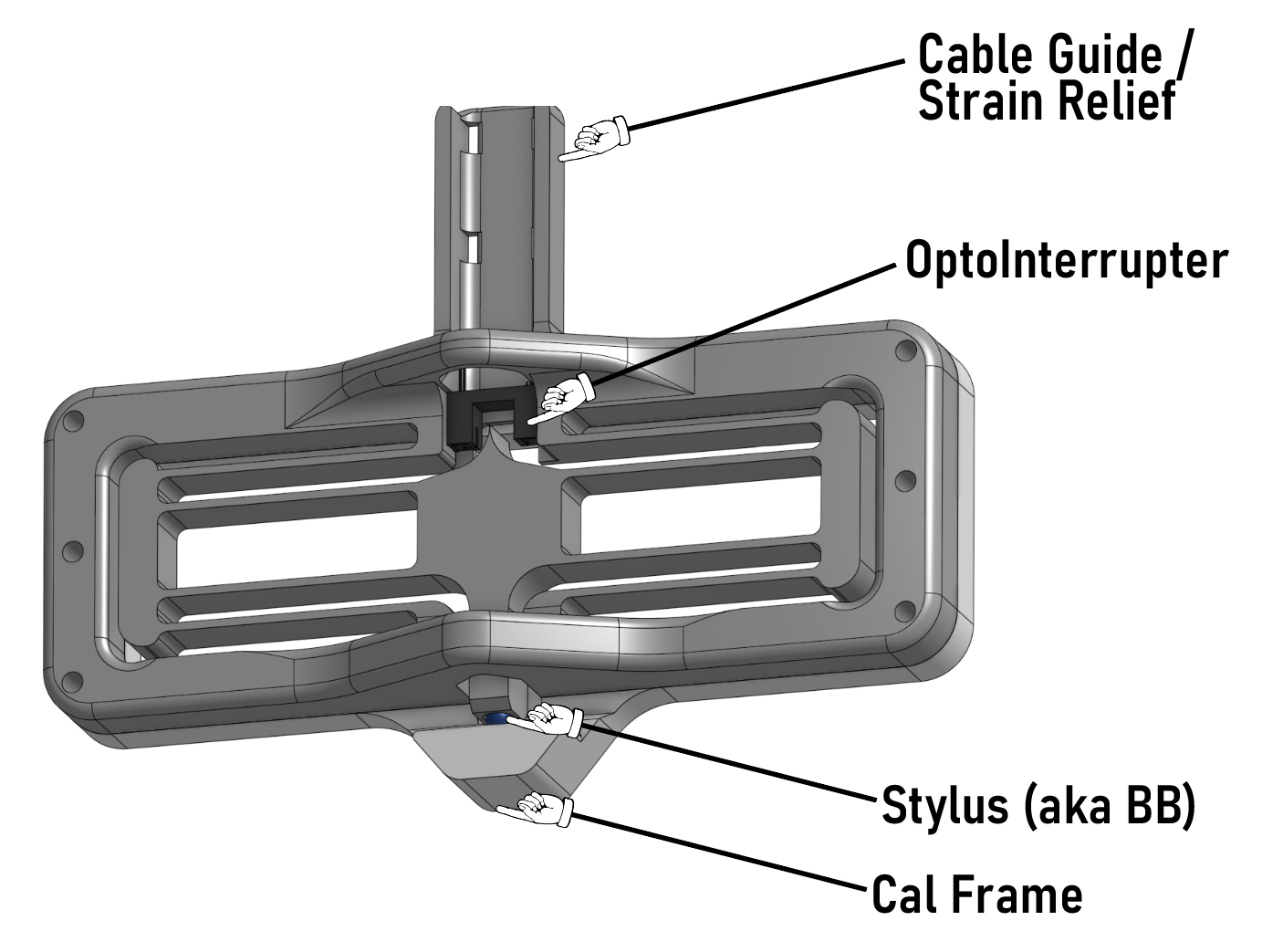

- FlexureFrame_BuiltInBlade

- CalFrame - If you plan to calibrate similar to how I do below

- COTS

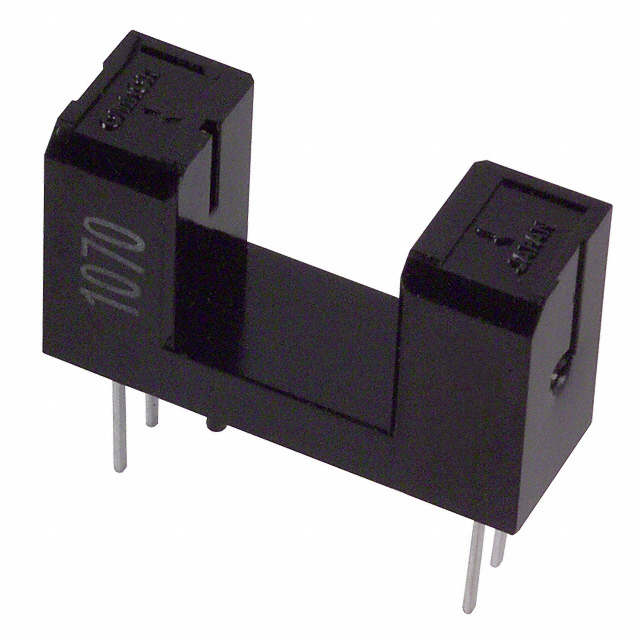

- EE-SX1070 - OptoInterrupter

- 4.5mm Steel Ball - aka a bb. This is your stylus tip. Anything hard, spherical, and around this diameter should work. I've been using these, partly for the hard anodized finish...no clue what the other part was :) but they've worked for me as styli and in bearings and such just peachy.

- Glue - I recommend super glue of your favorite variety. I used this medium viscosity stuff.

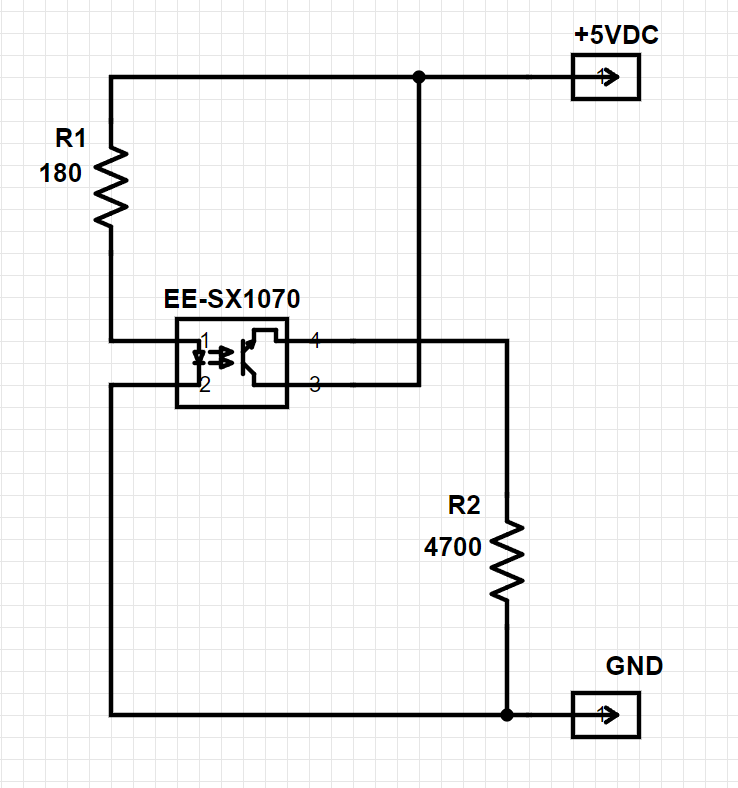

- Resistors - I used one 180 Ohm and one 4.7 kOhm

- Wire - I used some old scrap telephone wire

- Attach wire leads to the optointerrupter. I usually crimp on Molex female connector pins onto the ends of the wires. I then slide these on to the pins of the opto and then solder them secure. If you have a more elegant solution that you like, I'd love to hear about it in the comments, but this works well enough.

- Assemble the circuit (see Electrical section below for how I went about this one)

- Feed the wire leads through the arch above where the opto sits in the frame. Feed them all the way through so that the opto is approximately in the right spot. You'll set it's final spot shortly. Also, there are two sets of openings in the Cable Guide for zip ties to provide some strain relief. I like to go ahead and put the zip ties in at this step, but leave them as just loose loops. Waiting to tighten them once the glue has fully set after step 6.

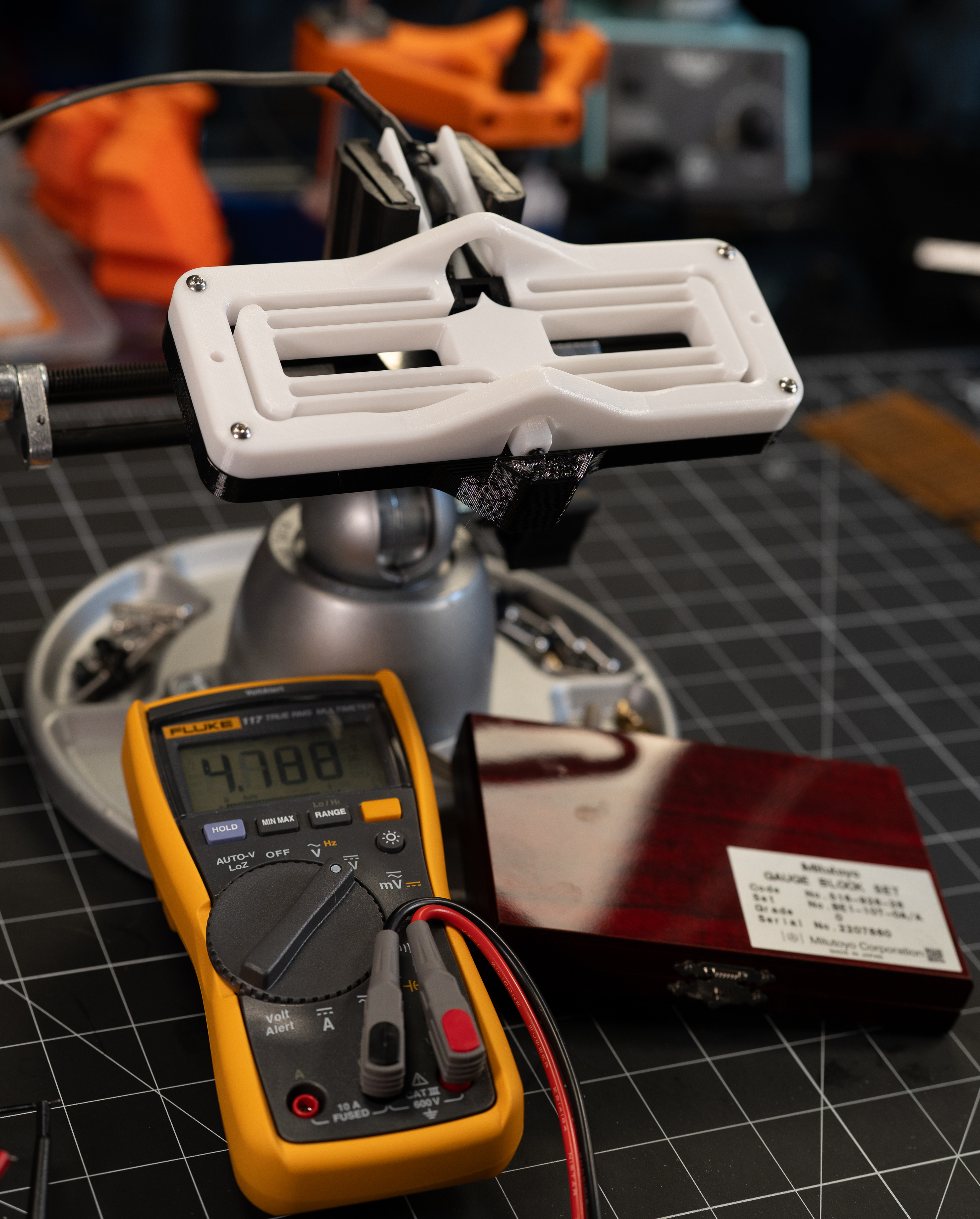

- Connect the wire leads to their appropriate connections on the circuit, and power on the circuit.

- Hold the opto so that the bottom side of it's U shape is pressed against the plane behind it, and slide it until the output voltage is ~5-10% below the voltage with nothing disrupting the beam. Make sure there is nothing causing the flexure to be deformed while setting this. The goal is to position it such that the plastic 'blade', is inside the measurement range at no displacement. The 5-10% is to try to get away from the highly nonlinear response expected at the ends of travel.

- Once the sensor is positioned to your liking, apply a small drop of glue between the side of the opto and the printed plastic wall next to it. I like to glue one side while using my hand to keep pressure on the other side. Once that side has set (30 seconds or so) I repeat it on the other side.

- Tighten the zip ties in the Cable Guide. Be careful to make sure you don't put a strain between the zip tie and opto. The goal of these zip ties is to isolate the sensor from any downstream tugs, bends, etc.

- Put a small drop of glue in the cone for the stylus, and apply some pressure to the stylus/ball while the glue sets. Don't push too hard, and preferably provide some support so you aren't just pressing against the flexure.

Electrical

Or, to tie this in with an Arduino, instead of just reading the voltage on a multimeter:

Here I've just added in an Arduino Nano (I used one of these generic versions) to read the sensor voltage.

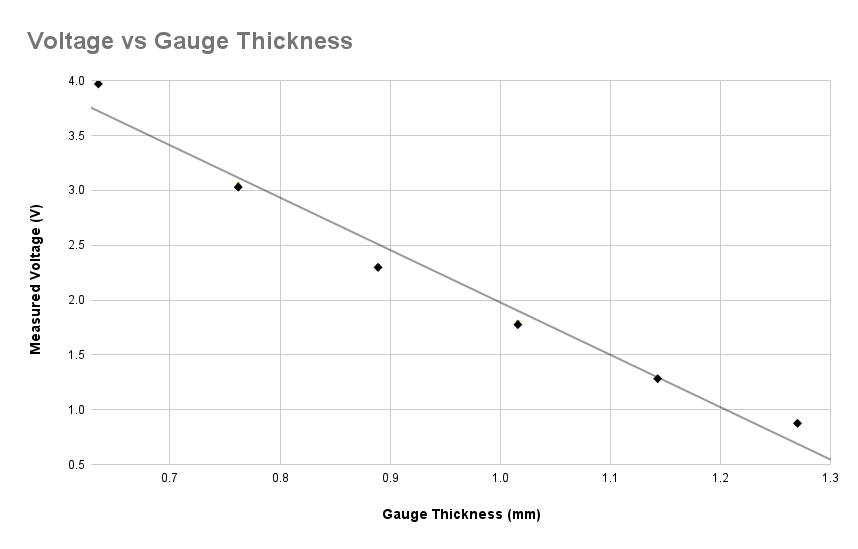

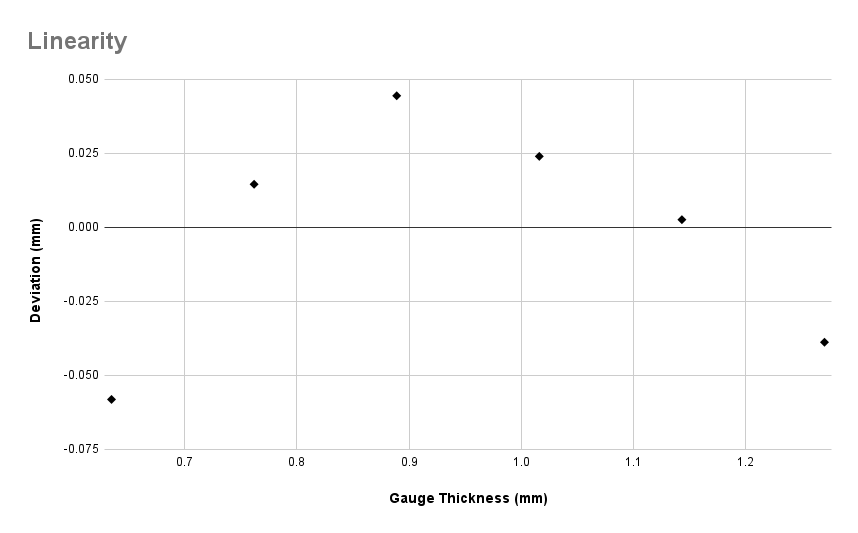

Calibration

Process

Results

Design Notes

2024/01/20 - Initial design

2024/01/22 - V2

2024-01-24 - V2 Setup and Cal

- Details

- Parent Category: Just Playin and Concept Demo Projects

- Category: Flexure Fun

Overview

I, like pretty much every engineer I know, was absolutely enamored with the idea of fractal vises from the first time I encountered one.

At some point along the way I finally gave in, and decided I wanted to try my hand at making one for myself. But while I do have some basic machining equipment, I don’t want one of these quite badly enough to go that route, so I wanted to find a viable option for a 3d printed, or mostly 3d printed variant.

I tinkered with some concept designs for print-in-place versions, and other printable variants of the same general concept for the classic flavors. But then it occurred to me that the bearings/bearing surfaces could possibly be replaced with flexures that create a virtual pivot along that same line. Below are my attempts to date in testing this out.

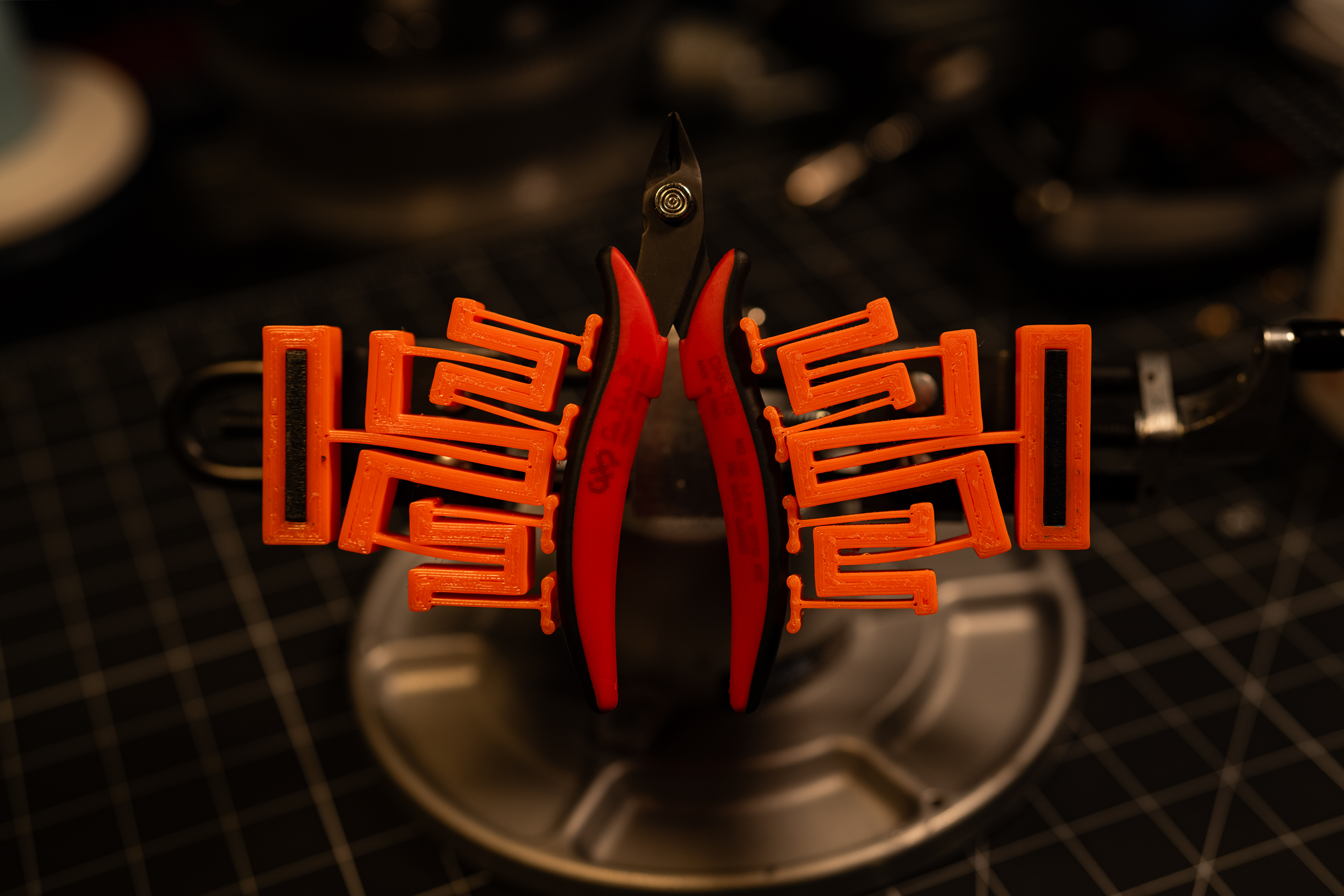

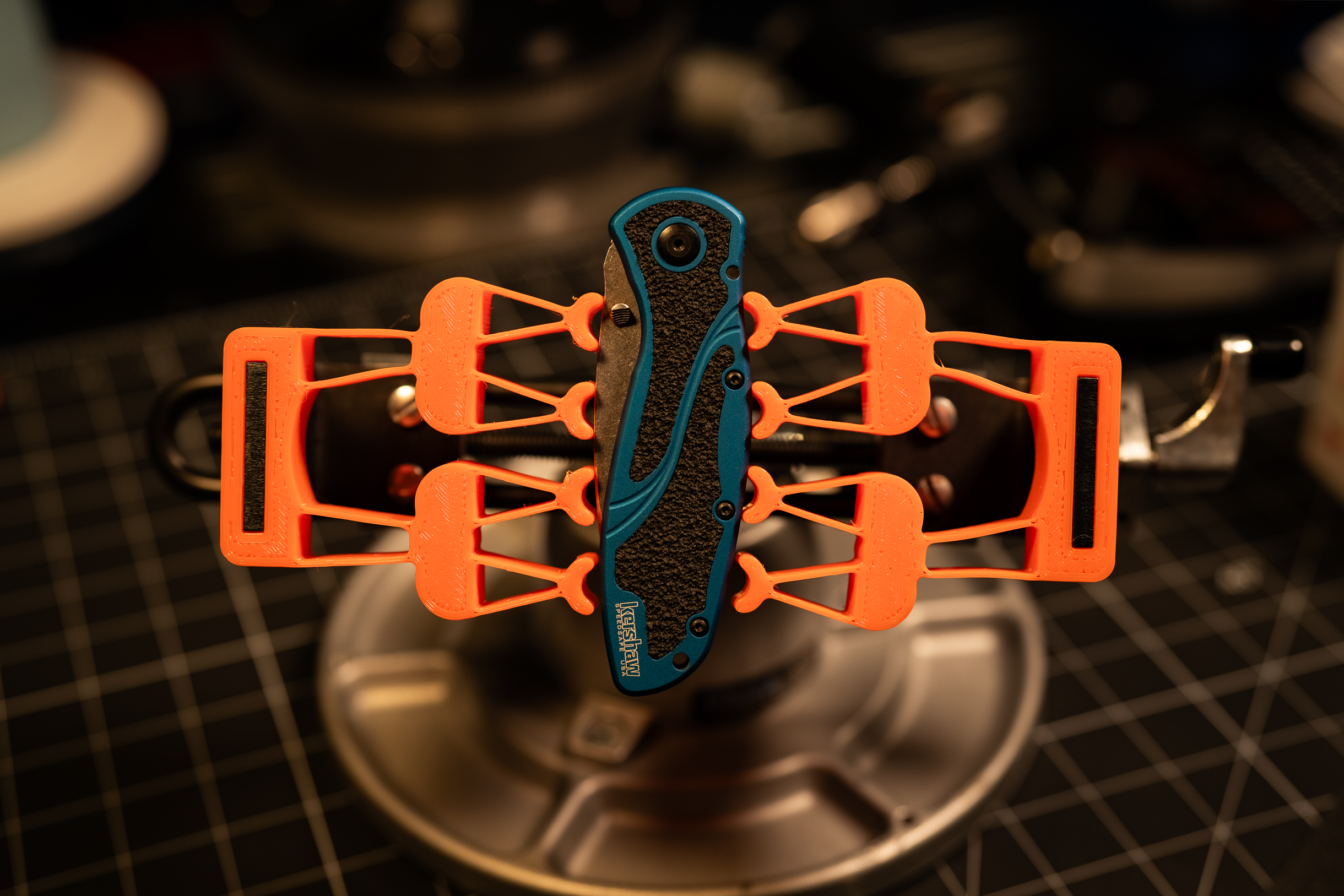

All of these jaws are designed to fit onto my Panavise 350 jaws (see below GIF).

If you aren't familiar with fractal vises, I’d recommend watching one of the awesome videos folks have made (a handful of ones I’ve enjoyed personally are below).

Versions

Models for V5 and V6 can be found on OnShape here. I'd need to find where I did 1-4, but if you're interested, just let me know and I can dig em up.

V6

This rev is essentially just a slightly beefed up V5. I thickened up the jaws themselves (the V5s were intentionally a bit thinner than desired to speed iteration), and also thickened the 2nd and 3rd order flexures, counting the jaw flexures as layer 1.

I also significantly thickened the out of plane thickness as it gets closer to the jaw. This was primarily aimed at increasing the torsional stiffness overall as well as to allow the jaws to rest on the Panavise bracket instead of ‘floating’.

V6 "Booties" - by @aoty

A user on Printables came up with these awesome little 'booties' for the vise jaws...I must admit, since I originally was calling this "Flexure Fractal Fingers" (to noone but myself, of course), I can't stop callin these 'fingertips'. But I think @aoty's 'booties' moniker is better.

They're intended to be printed in TPU and to give the jaw teeth some better grip. I printed some in both TPU and resin, which I thought was 3dMaterials SuperElastic, but based on the parts, I think Past Bubs may have put some SirayaTech Fast Smoky Black (my 'daily driver' resin of choice) into the 3dMaterials container. It does seem to have some elastic material in the mix, but it's far too stiff to be the SuperElastic...plus it's smoky black....so there's that.

I think these little things are great! One of those, "wish I'd thought of this" things for sure. They give a nice bit of extra grab on parts, and given that I've had more than one part come flying out of what is essentially a springloaded vise, so these are damn-near a safety requirement now for me

The resin parts look great (IMHO), but the TPU wins hands down for performance. So naturally I'll be leaving the resin ones on

V5

V1-V5 files can be found here: Printables | Thingiverse

V4

Shortening the leafs made the two small 'stages' to be far too stiff.

V3

This has been the best performing of the four bar designs thus far, but turns out that final pivot for the full jaw is important. Without it, the jaws can't accommodate an overall wedge.

V2

Worked ok, but I think the lever arm between the contact point and the pivot point is too small. As a result the clamp force has to be quite high to drive deflection into the flexures.

V1

Ummm, yeah....I think this one looks cool as hell!...but it doesn't fit on the Panavise 🤦♂️

Fractal Vise Videos

This one from Adam Savage is a fun look at both a fractal vise, and the general joy that they bring hardware nerds:

https://youtu.be/NUhrF0xkhhc?si=YvwaEeE7oxlwUBhj

Really nice restoration video

https://youtu.be/QBeOgGt_oWU?si=QO1tu4-0Jl_mqmxz

A really nice 3d printable option:

https://youtu.be/eCfw9fd0mHg?si=knRpBk3tQjuHg-MT

- Details

- Parent Category: Just Playin and Concept Demo Projects

- Category: Flexure Fun

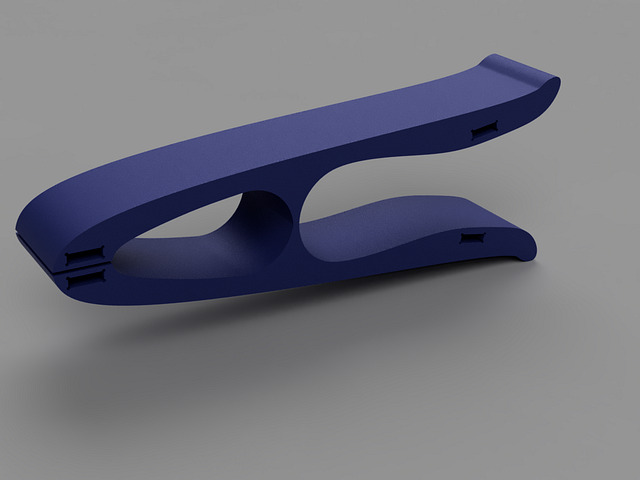

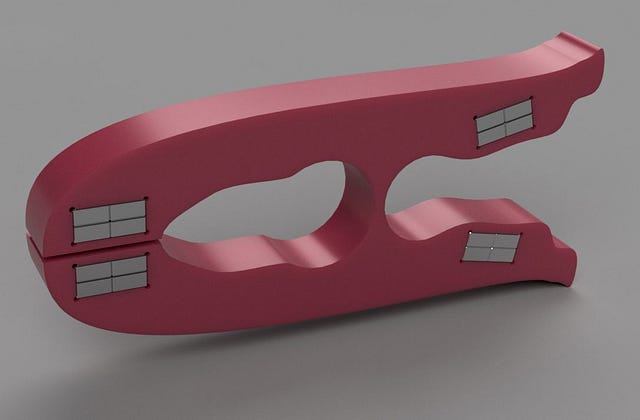

Concept is to use magnets to provide the closure force for a bag clip. Original concept also included a magnetically preloaded kinematic hinge concept, but it had a higher parts count and was a little bit of a PIA to assemble, so I switched over to this flexure hinge which I think/hope will be all around easier!…here’s hopin

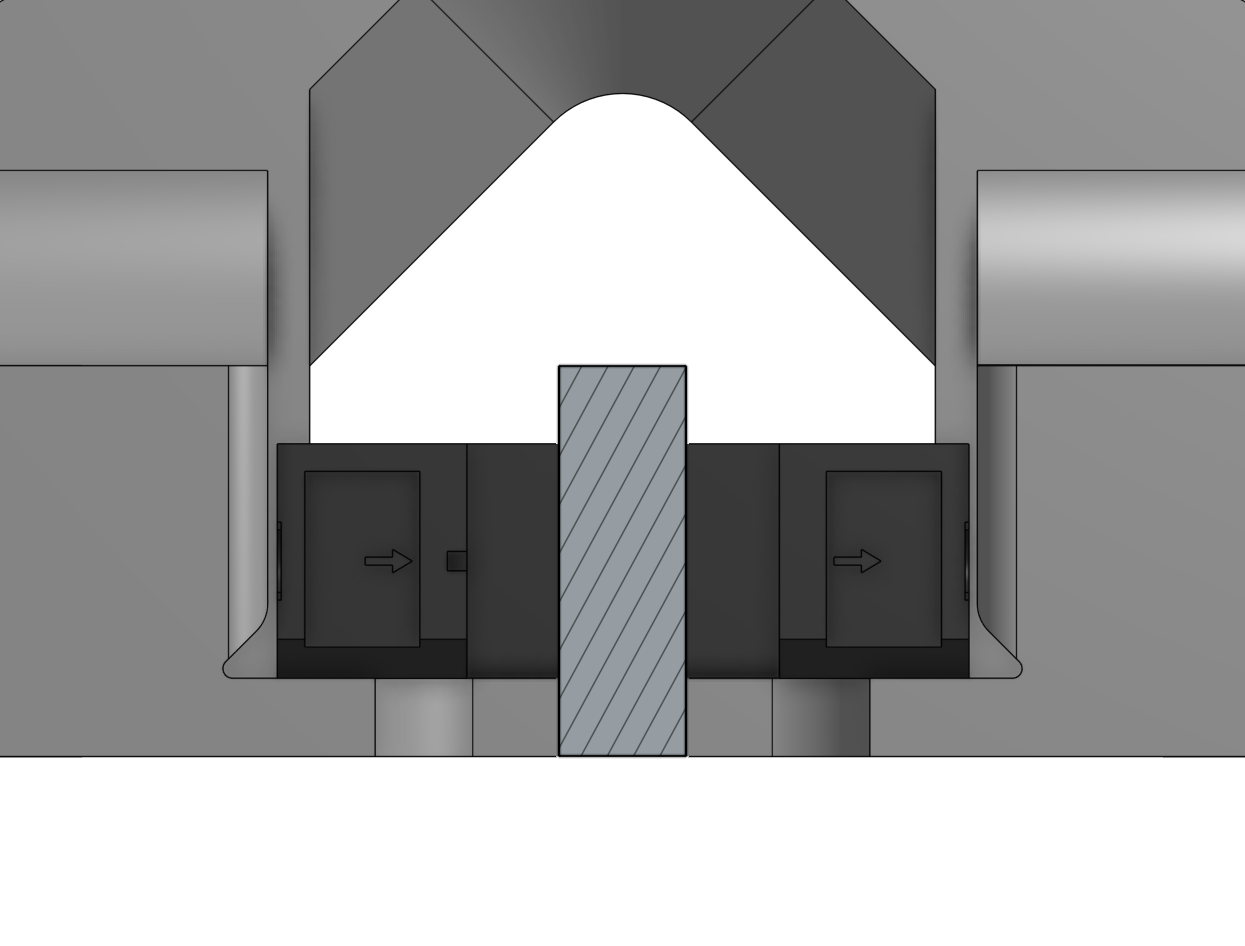

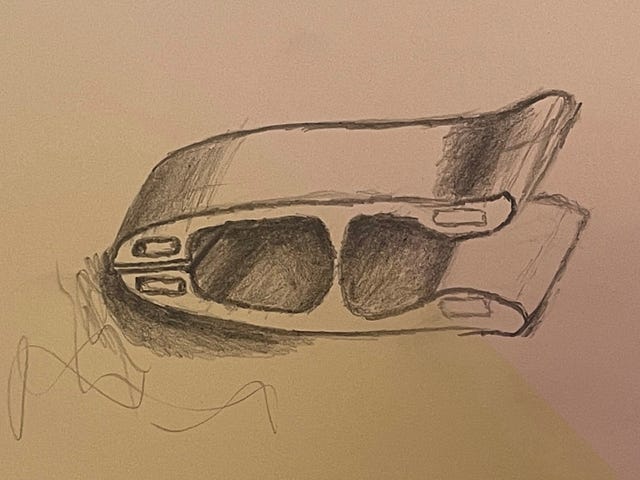

Here is the hammock sketch…I mean, “concept sketch” :)

The idea being that the magnets at the front are attracting and those in the squeezey side are repelling. This config should help linearize the force of the magnets (kinda :) ). In the center is a notch flexure that will act as the hinge. I was aiming for a simple constant cross-section to make for a quick, easy test print.

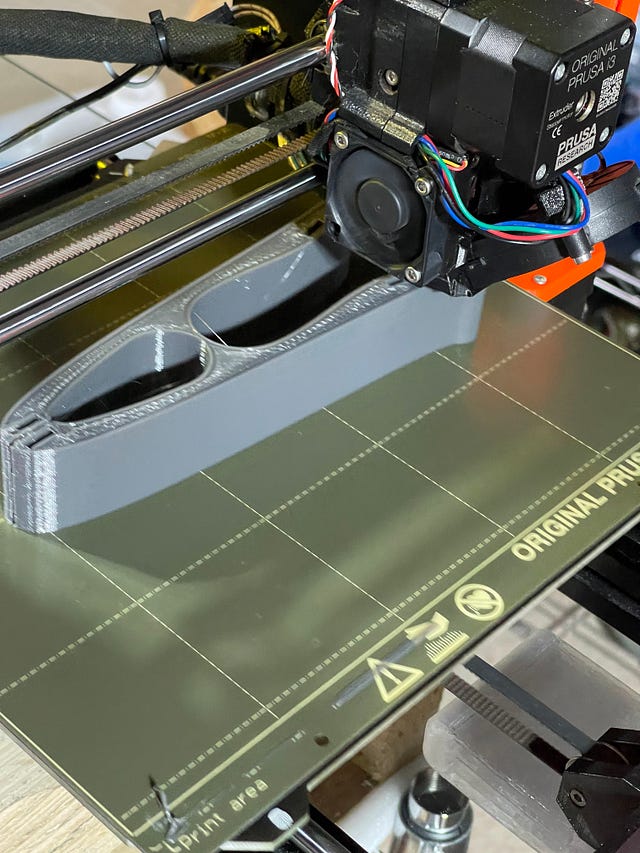

And here is the first rev in Fusion. As you can see I basically just copied the sketch. I designed around these 30x10x3 bar magnets. They are almost certainly going to be a little overkill, but I wanted to make sure to have sufficient field to overcome the gaps and hold the bag securely….we shall see (first test print running as I type :) )

I was a little disappointed in the strength of the magnets, and I definitely made the clamp longer than it needed to be (…length? I guess I don’t have a naming convention… Length == distance from one pinchy end to the other pinchy end….#engineered). But even with that, it works otay! And to be fair to the magnets, I think it’s probably a little unfair to expect them to permeate multiple layers of plastic AND whatever bag they’re on, so I should cut em some slack :)

But I did do a number of small tweaks, playing with magnet configs and dimensions. Here is the most recent version, and the one I’m currently using, but I’m sure another revision will come along once I get frustrated with this one for whatever reason. The most significant difference was the change in magnets. To make the print faster while I iterate, I decided to go with these shorter magnets…but lots more of em :) They are 12x6x3mm bar magnets in the same push/pull config as before. Although I made it ‘thinner’ to speed the prints, I kind of like the form factor on these. If you end up making some, I’d love to hear suggestions!

That’s all on this one for now!

Subcategories

Assorted (hopefully) "Useful Stuff" Projects Article Count: 12

Like the bucket of assorted fasteners on that bottom shelf, this category is for stuff that I didn't know how to group...oh, and speaking of those fasteners, check out the little sortin fella!

2020 Aluminum Extrusion Hardware

|

Quick Bolt Sorter

|

General Purpose Turntable - Gen1

Games Article Count: 1

Generative Design Projects Article Count: 3

During the good financial decision-making times of Covid lockdowns, etc. I decided it was a good idea to buy a license for the Fusion360 Generative Design extension...Good news, I did finally pay that off :) I had worked around, and been somewhat involved in a handful of Topology Optimization/Generative Design projects through my work, and I've found the tech super interesting for some time. So after the free trial, and feeling like I was just starting to gain some level of competence in Fusion360's tool....I done did it, and bought the year. Ok, now that I'm done justifying that to myself...I mean you...

<engineering/design> What I really like about Generative Design is that it forces the designer to think about the thing they are trying to design from it's core requirements: Forces, Interfaces, and Keep Outs. I think it's far from perfect, especially given the still very primitive Design For Manufacture capabilities these tools have (among other shortcomings, but this one is certainly a big one to me.)

<precision engineering> One last also (for now), but ALSO, what I find exciting about these tools from a precision engineering perspective, is that the above-mentioned focus on forces and interfaces, these tools are extremely well-suited to kinematic/exact constraint designs! I think every one of the Generative Design projects below features at least some aspects of kinematic constraint (I say, "I think" because I may or may not be writing this before I go through my files and remind myself what all I actually made vs what I just thought about making ¯\_(ツ)_/¯ )

JFS Projects Article Count: 14

AgTech (aka finding a way to complicate and digitize gardening) Projects Article Count: 12

Hydration and Hydroponics Projects Article Count: 8

Peristaltic Pumpin Article Count: 4

A lot of projects I work on/have worked on seem to involve the controlled movement of fluids. Below is a bit of a history of my builds involving attempts at obtaining this controlled movement for incompressible fluids. I haven’t done much myself with making custom solutions for the compressible stuff, but if you’re interested in such things, I thoroughly enjoy Major Hardware’s “Fan Showdown” series :)

This article/section is by no means intended as a thorough overview on the design and operation of pumps. While I will try to give some overview on operating principles and design considerations as I go, this is mainly just going to be a wander through my personal builds and experiences.

Peristaltic Pumps

What is a peristaltic pump?

I’m sure there are innumerable sources online for (much better) detailed discussions of the workings of peristaltic pumps. So I’m just going to hit the highlights, and I’ll try to remember to find some promising links and add them below, should a deep dive seem intriguing to ya.

Basic Operation:

The fluid being pumped is carried into the pump in a compliant tubing. This tube is routed around some portion of a circular/cylindrical path around the axis of the pump and then exits the pump. This is one interesting/attractive aspect of peristaltic pumps, the fluid never has to leave the tube that it is in, making these pumps well-suited to situations where contamination and/or leaks are highly undesirable. The housing that features the cylindrical wall that the tubing is being routed along can be considered the Stator, and that is generally the nomenclature that I tend to use.

So if there’s a Stator, there must be a Rotor…? Yup, the rotor includes some set of features that extend out to some defined gap between this feature and the Stator wall. These features, which in many peristaltic pumps are rolling element bearings, pinch the tubing to the point of sealing (ideally) the tube. As the rotor turns, this contact point proceeds around the circumference. Because the pinched point of the tube is sealed, the volume of fluid in the tube ‘ahead’ of the pinch point are, as a result, pushed forward. So, keep rotating, keep pushing….pretty much as simple as that!

Pros:

- Positive Displacement Pump

- Because the pinch point is (ideally) fully sealing the tubing, the amount of fluid moved is directly proportional to the movement of the pump. This makes them very good choices for things like dosing pumps or other applications where the desired volume of fluid to be moved needs to be deterministic.

- This is a large driver for my initial interest in using peristaltic pumps. Their deterministic flow is/was very attractive for my plant growth experiments. They can give very repeatable watering volumes and nutrient concentrations.

- Fluid Isolation

- Because the fluid never leaves the tubing, these pumps can be suitable for moving hazardous materials. For example, I have been using a peristaltic pump for transferring 99% IPA

- Relatively Simple Construction

- Because the fluid does not have to be sealed within the pump, these pumps lend themselves well to DIY builds. No shaft seals, gaskets, etc. or complex (at least to do well) impeller design needed.

- Self-priming and Head height

- If well-sealed, these pumps are capable of self-priming (and even pumping air) and of achieving pretty impressive head heights (the measure of how high above the pump it can pump a column of water)

Cons:

- High drive torque

- Because of the preloading needed against the tubing, and the rolling friction, even with good rolling elements (more below on this), it can be quite easy to end up with designs that require quite a lot of drive toque.

- Tubing wear

- With the relatively large deformation and high number of cycles, the tubing will eventually fail, either due to material wear, fatigue cracking, or who knows what else. Because this failure mode can cause fluids leaking into your pump not designed to experience this fluid, this failure can potentially be quite problematic. So the use of high-quality tubing material and a plan for periodic maintenance, are worthwhile.

Test Build 1

A couple of years back, I had a concept for an in-line-mixing hydroponics system. The idea being that the supplies to the system would be just pure water and nutrient concentrates, and a series of pumps and valves would allow precise dosing mixes to each target plant in a system (I refer to this concept as Rail Yard Hydro, since it moves the fluids around the tubing network quite like rail cars are moved around a rail system. I’m planning to add a separate page diving into that one a bit deeper since it is the design scheme I am using in my current projects.)

Well, to facilitate this plan, I wanted to find an option for a dosing pump that I could integrate in to my control system (aka Arduinos and Raspberry Pi’s :)). Unfortunately, I quickly found that a servo-driven peristaltic pump could easily set me back north of $100….so I set out to spend many multiples of that making my own!

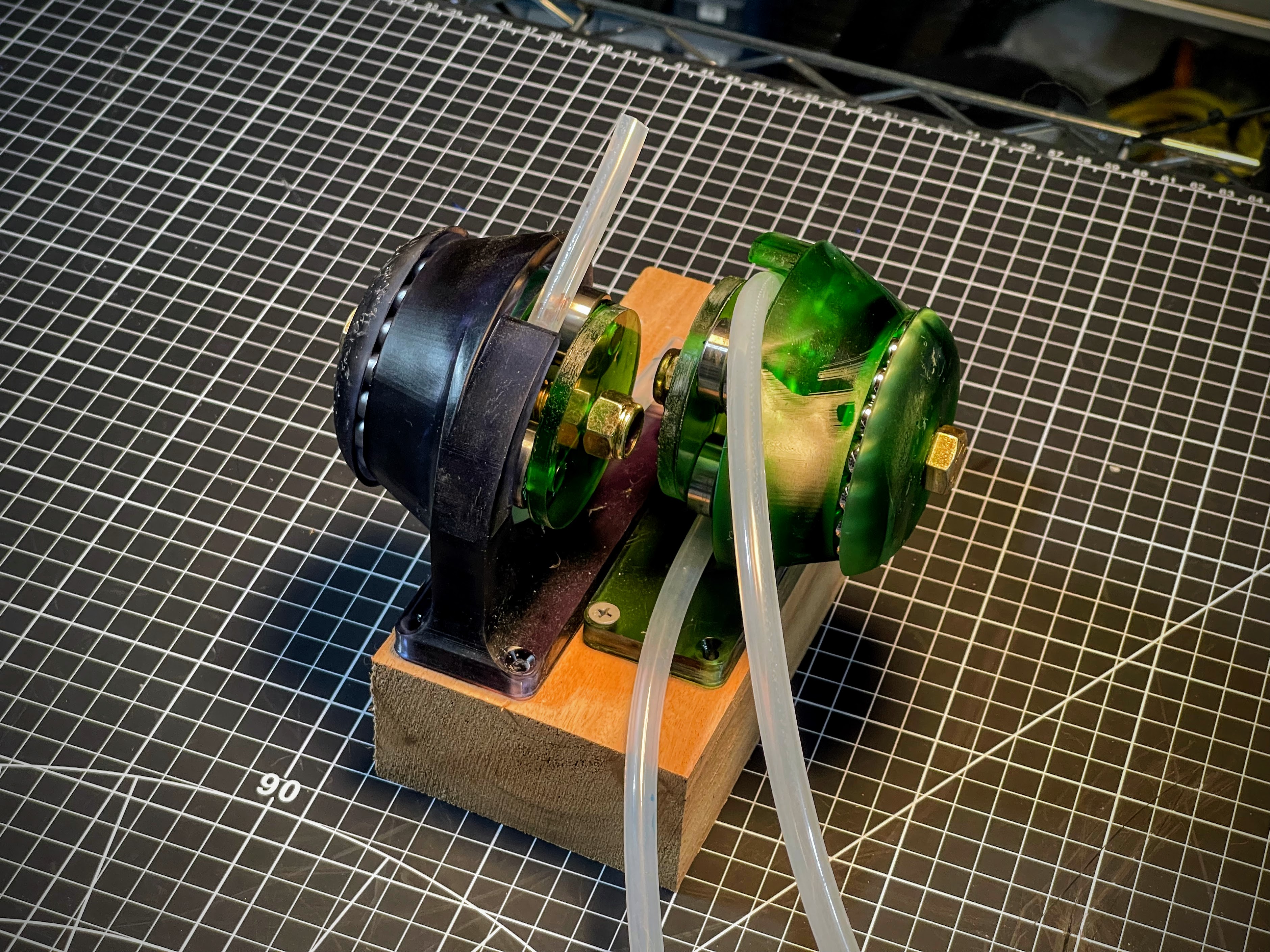

Actually, when I saw the pricing, I decided I should see if I could make myself a cheapo, manual version that I could use to just test out some basic questions on the Rail Hydro idea (mainly verifying that I could induce good material mixing in-line and that there was no cross-contamination between fluid reservoirs.) And so, ‘twas this endeavor that resulted in the pump I’m apparently referring to as “Test Build 1”

Design Objectives:

- Be a peristaltic pump

- Provide a full seal (at 100mm head)

- Be hand-cranked

- Not require any parts that would have to be ordered (I’m impatient)

The Build

She ain't pretty (especially after a good while of getting knocked around), but the pic above shows the dual pump setup I rigged up for my testing needs. I was VERY pleasantly surprised that, other than a tweak to the hand wheel, these things worked pretty damn well!

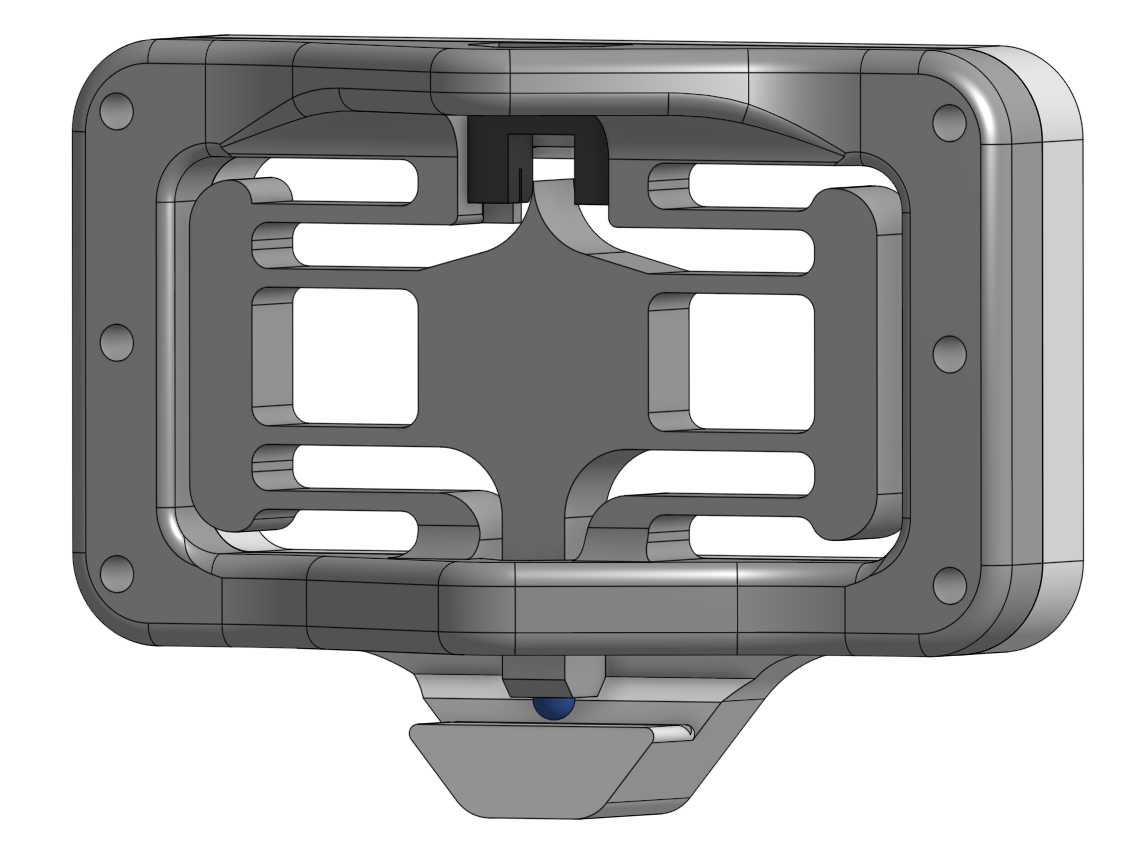

I decided upfront that I was going to go with a resin printed build, because I thought the high stiffness and good surface finish throughout the 'pinch region' would give me a better chance. Since I was already going to have the good surface roughness, I might as well also integrate the main bearing into the printed parts.

In the image of the model, below, the Stator is the part shown in green, and the Rotor is shown in blue(ish.) Riding on the rotor are roller skate bearings to provide the contact with the tube. Race 1 has v-grooves on both sides of the race, providing the main constraint for locating the rotor, and Race 2 has a v-groove on the Stator, but only a single plane of contact on the Rotor side. This keeps from over-constraining the bearing.

|

|

The absurdly overkill bolt running through the center is a real showcase of "using what I had on hand" :) in that these were the only bolt/nut sets I had on hand with the length I was looking for.