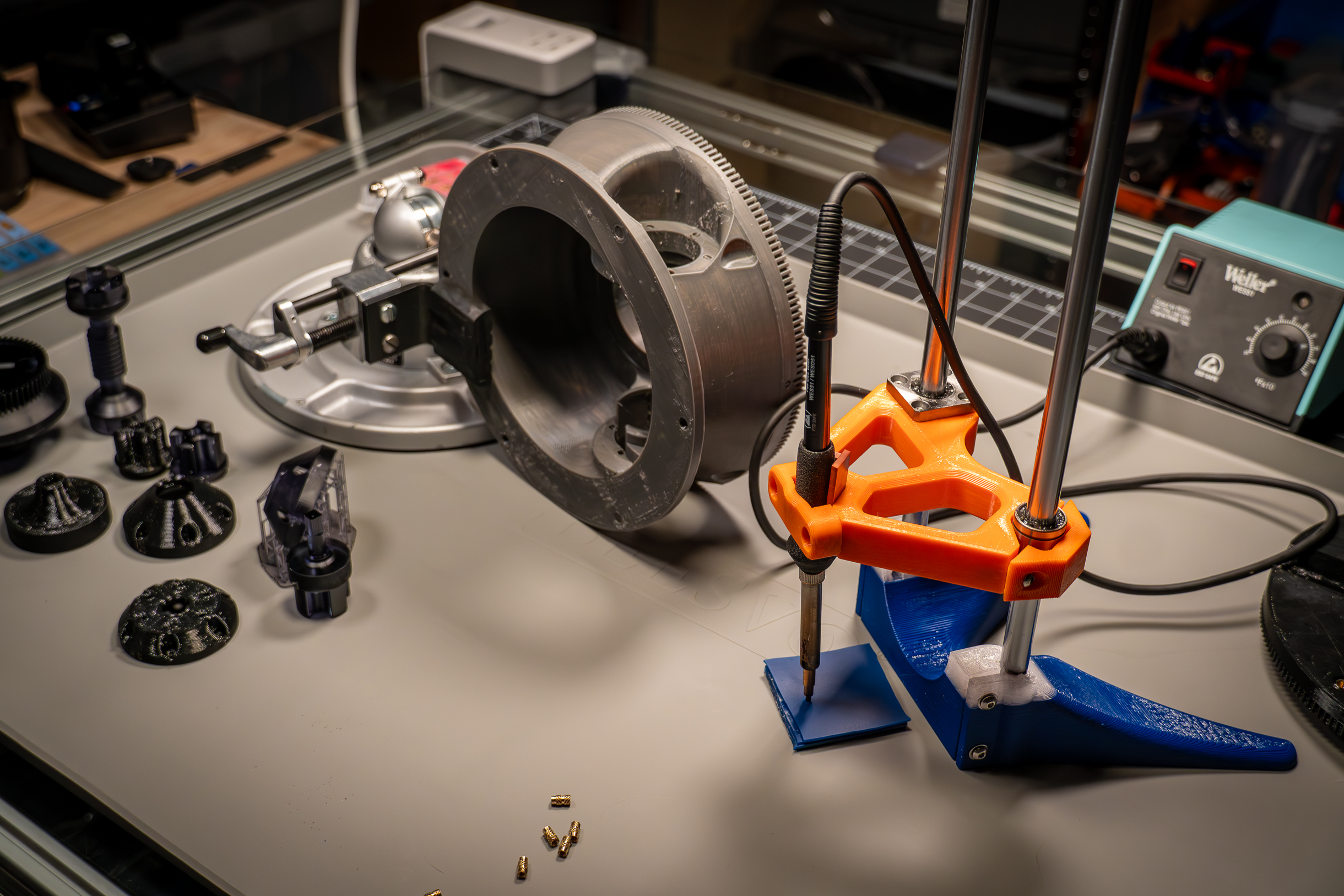

I had some extra linear rods and bearings around, and found the straightness of my heat setting skills lacking. So I tossed this guy together and have putting it to pretty steady use for the last few months. Figured if it’s proving handy for me, might as well share it.

I originally designed the clamp for use with my Hakko FX888, and more recently have been using it with my old Weller WES51. If your handle is too small, you could wrap it in some high-temp silicone.

- Printed Parts

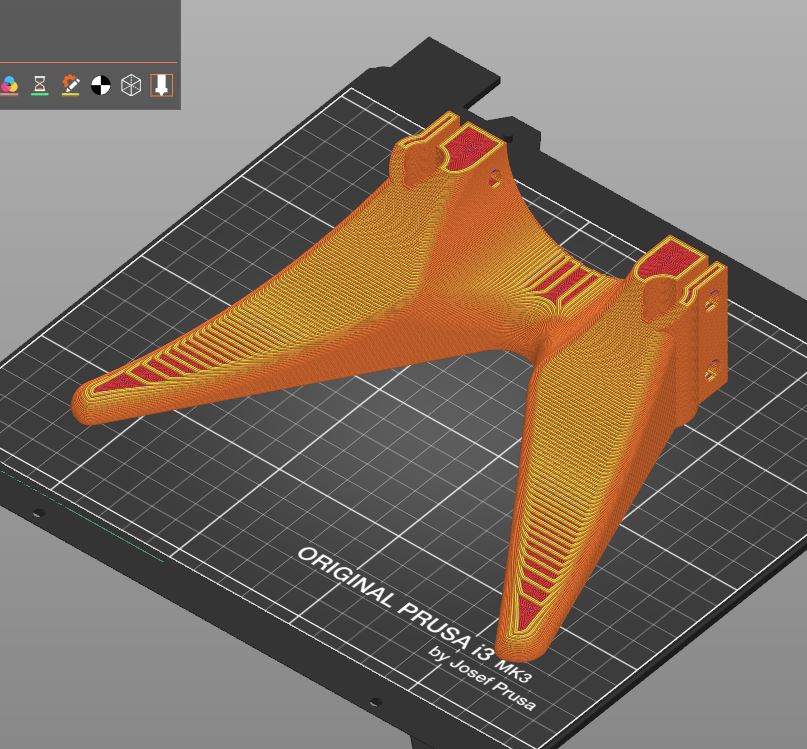

- (1) Base - 155g

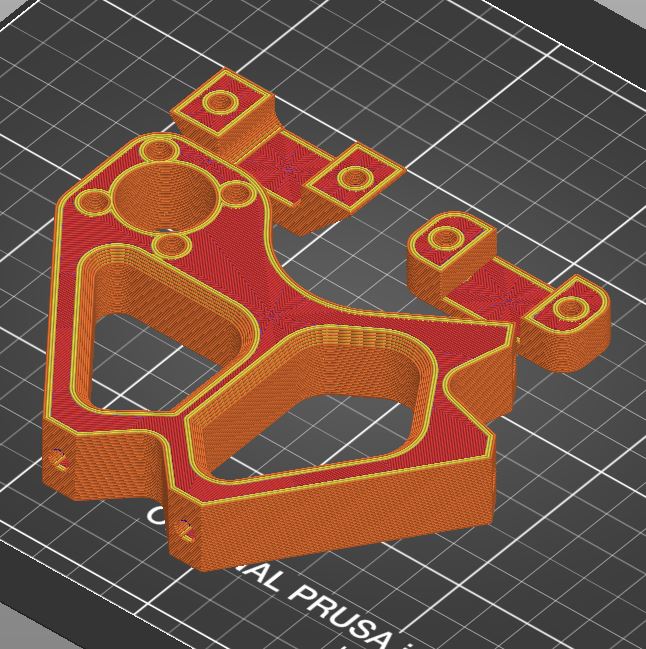

- (1) Carriage - 70g

- (1) IronCap - 8g

- (1) BearingCap - 8g

- COTs

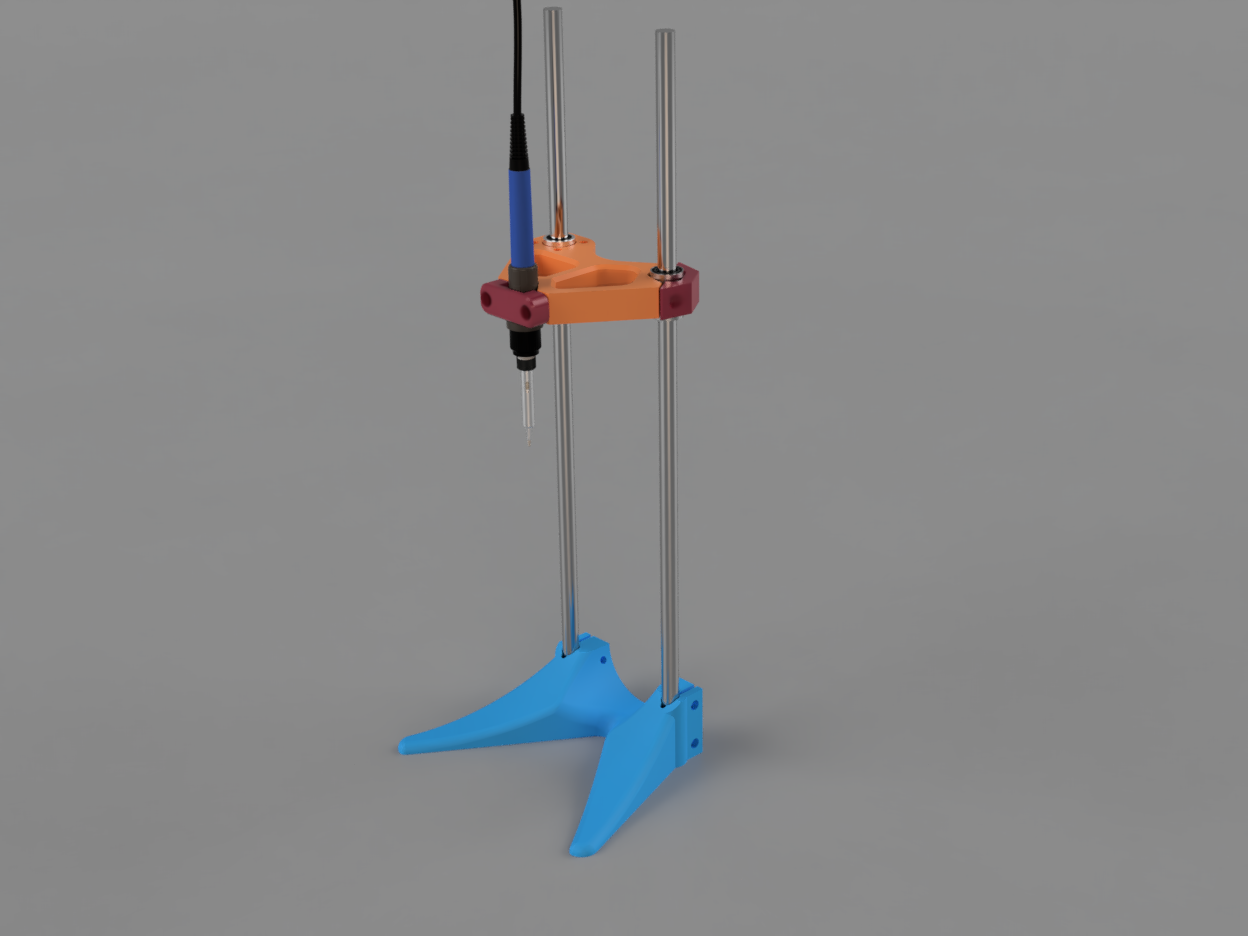

- (2) Linear Rods - I used these 12mm x 500mm rods (~$20)

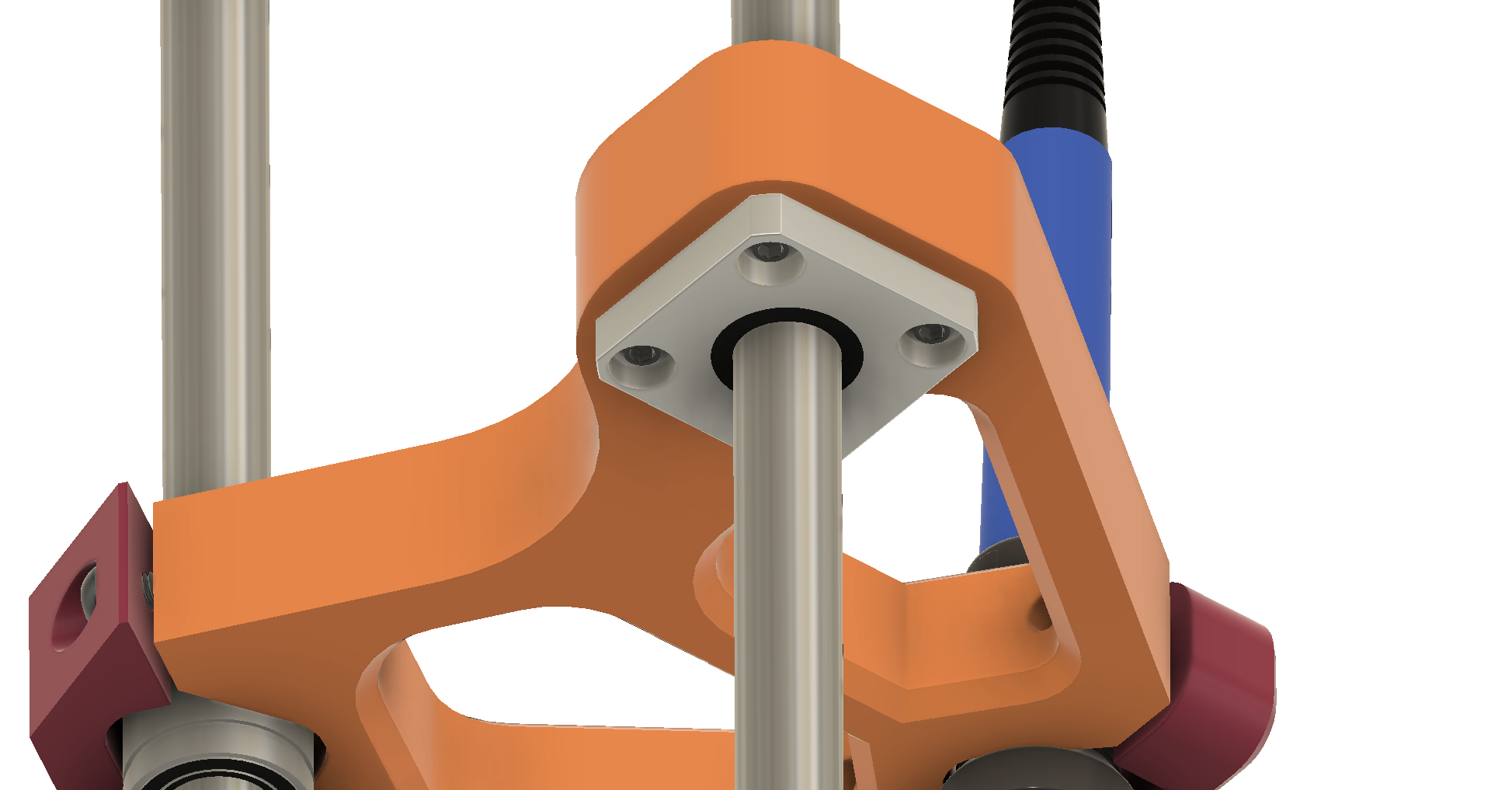

- (1) Linear Bearing w/Flange - I used one out of this set of 4 for ~ $17

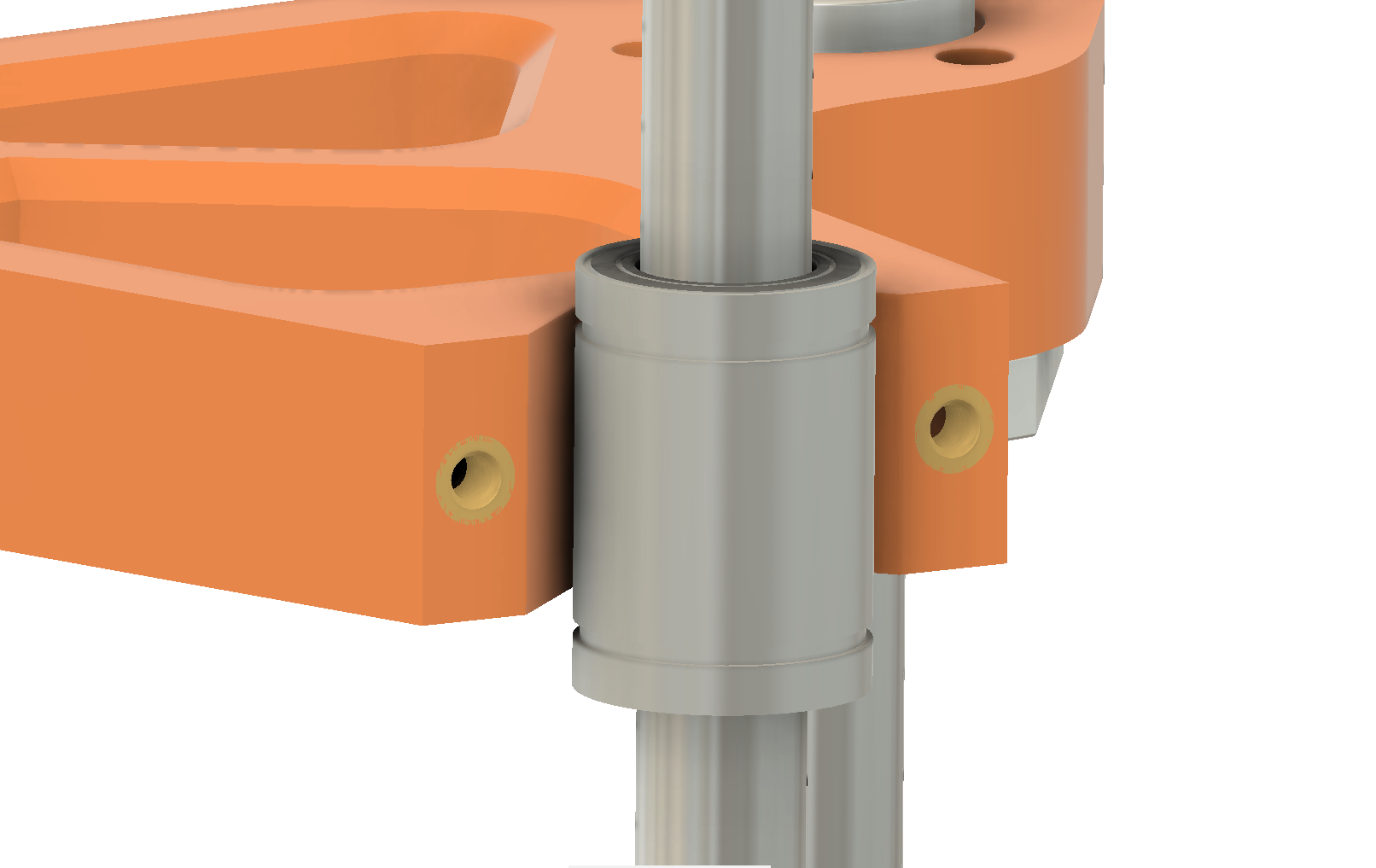

- (1) Linear Bearing - I used one from this set of 4, ~$12. You could probably also just replace this with another of the one above. They have the same OD, and so should work just fine in the clamp.

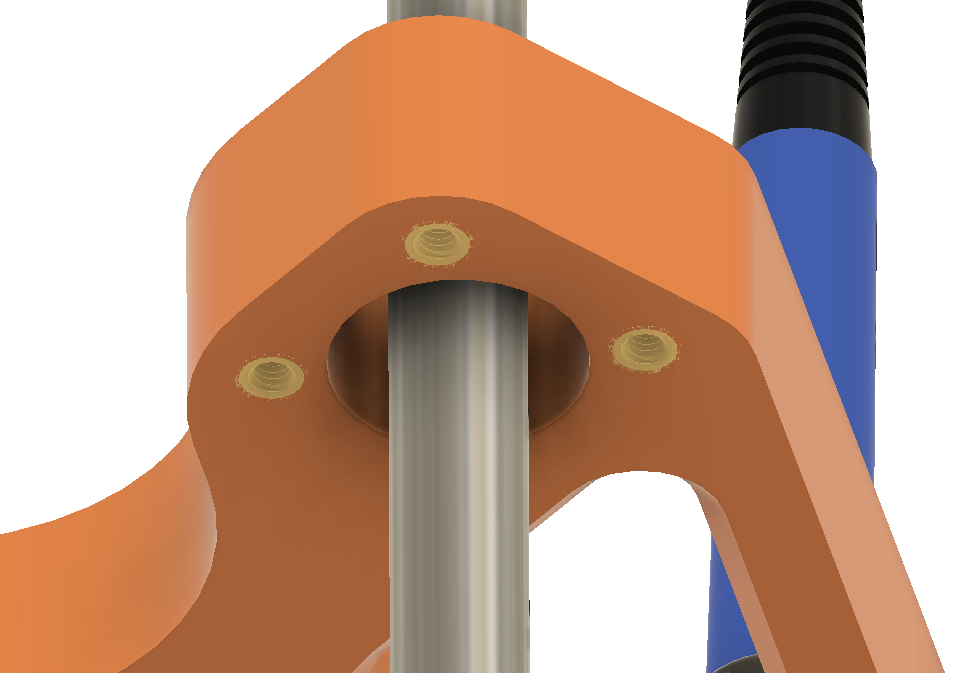

- (16) M4 Heat set inserts....the irony. I used some of these ruthex ones.

- (8) M4x10 BHCS - I got mine from this kit. For almost any of these you could use anywhere from a 10 to at least a 16.

- (8) M4x16 BHCS - Down to a length of 12 and no real bound on the top end.

- (4) M4 Washers - These shouldn't be entirely necessary, but if you have em handy, I'd recommend ya add them for the extra safety.

|

|

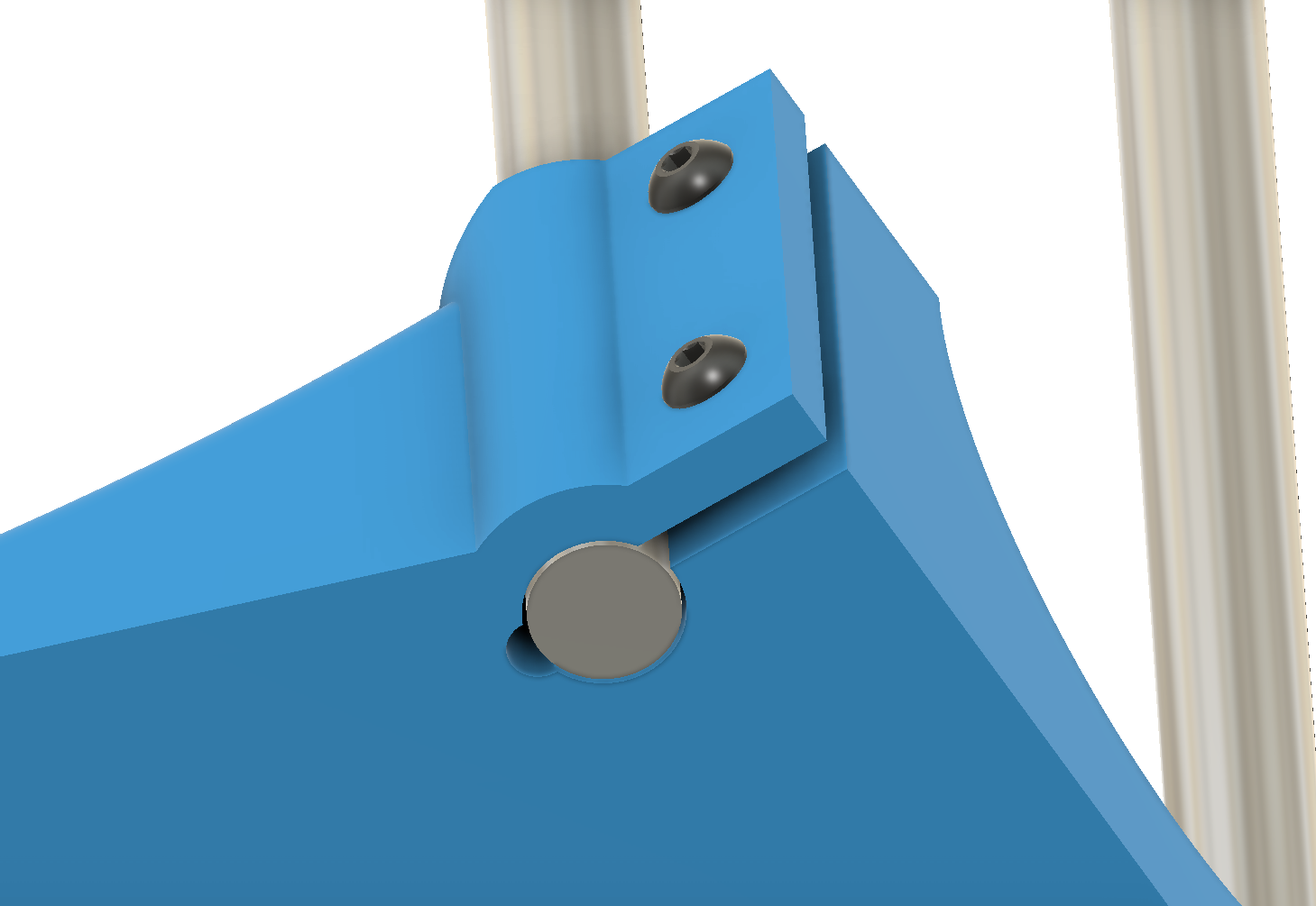

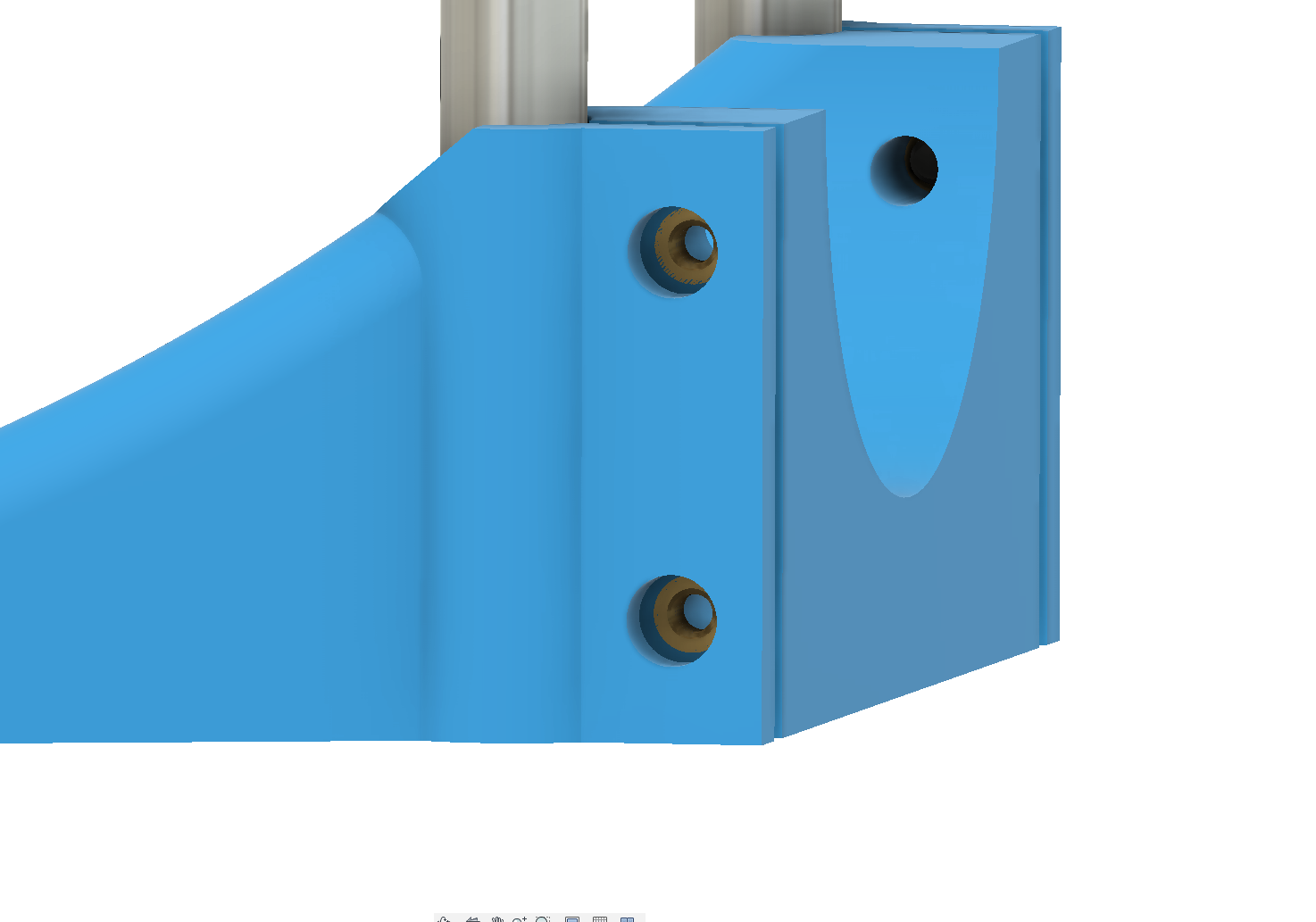

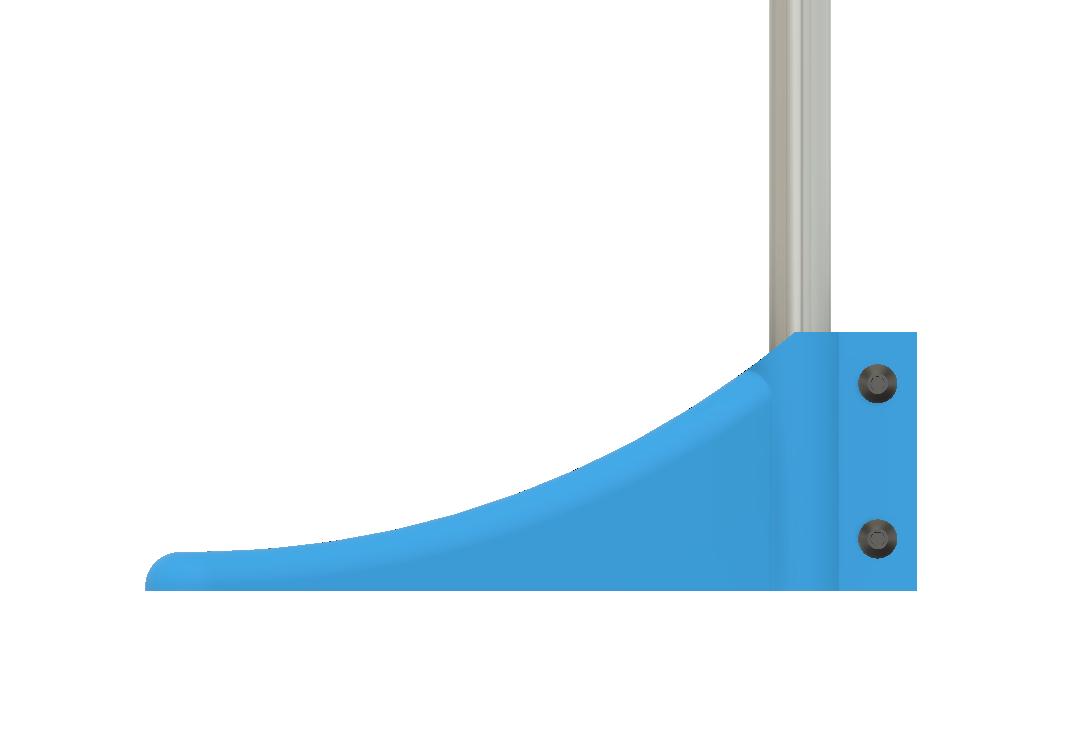

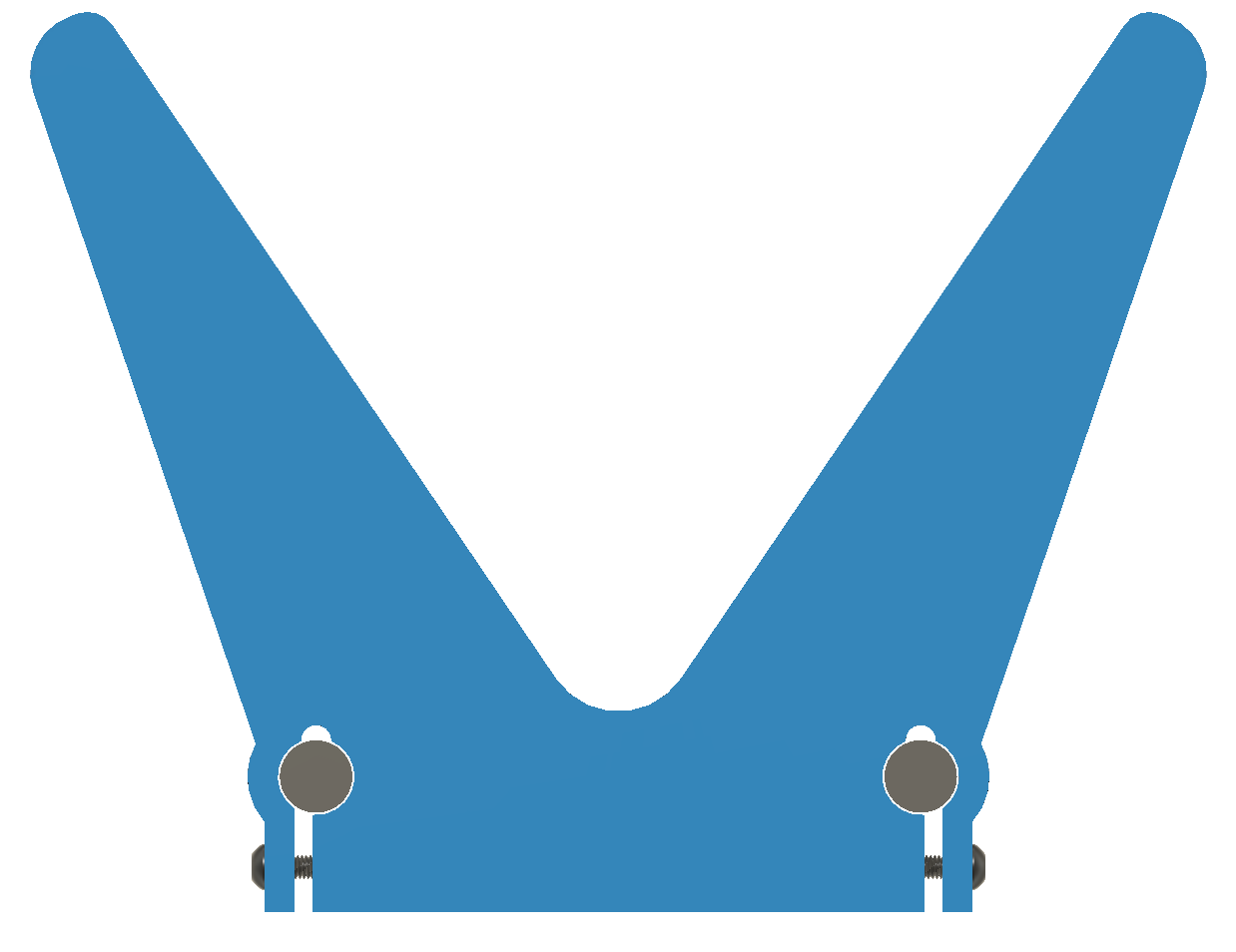

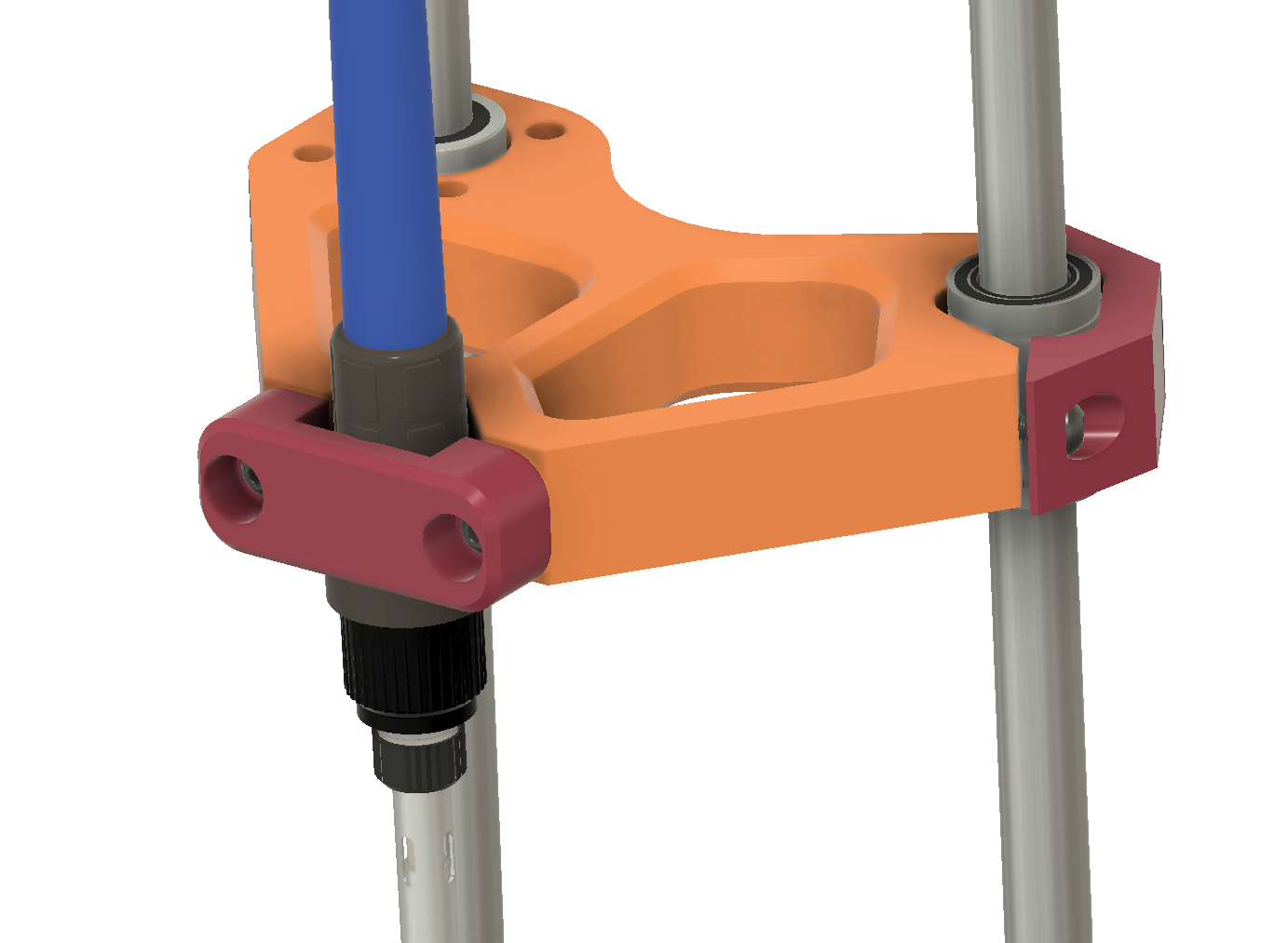

The linear rails are held in the split clamps shown below (and for this reason, I'd recommend printing them in PETG.)

Putting in these heat sets in the Base is a little tricky since the iron needs to go through the clearance hole for the fastener. But as long as you're careful, you shouldn't end up with a messy tip...nobody likes a messy tip.

|

|

On the Carriage side, all of the inserts should be pretty straightforward. I just set it up in the Panavise and went ta town.

|

|

|

|