Assorted connectors, brackets, and such I've made for designs using 20mm x 20mm t-slot aluminum extrusion.

Hinges/Pivots

Design gist

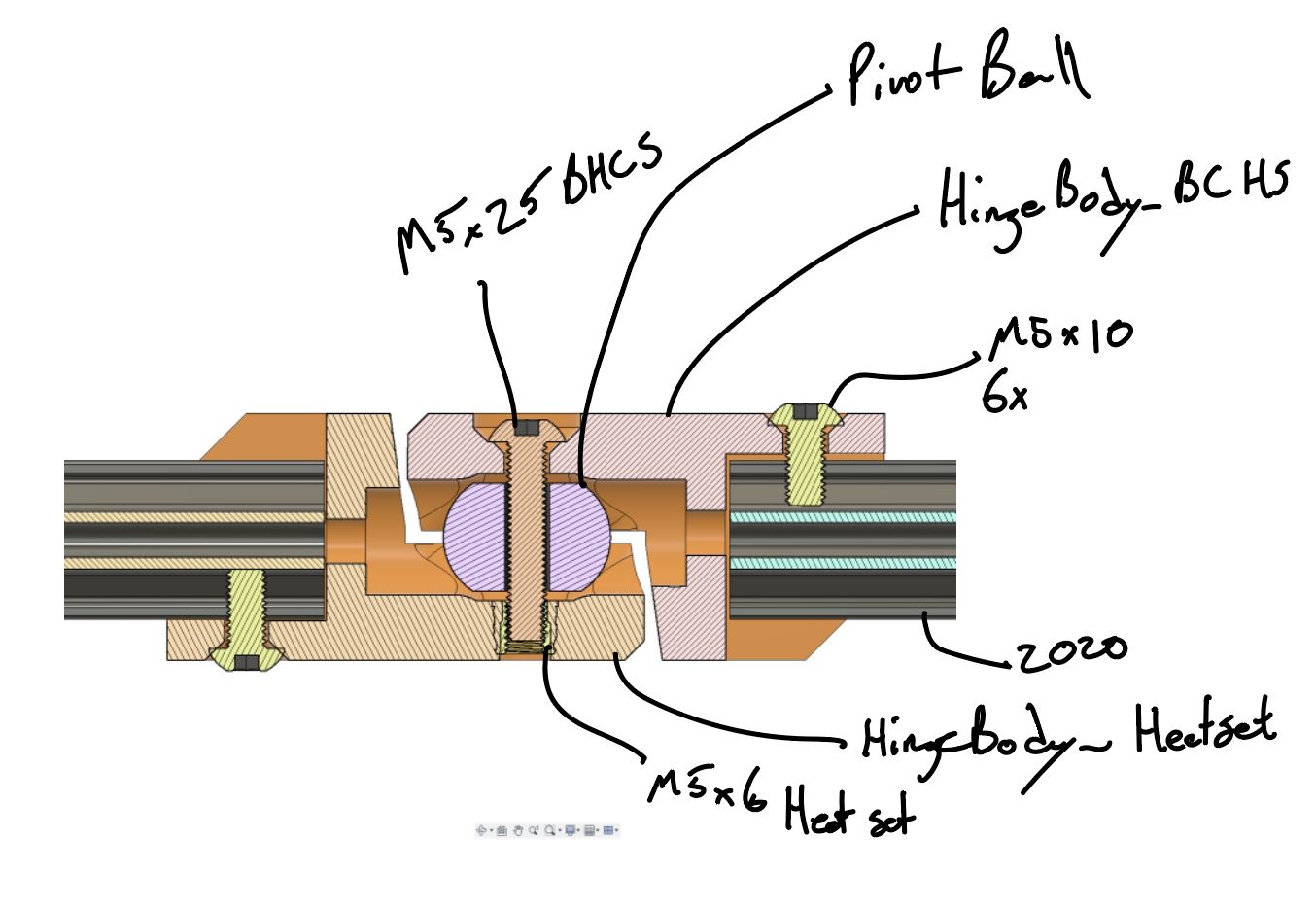

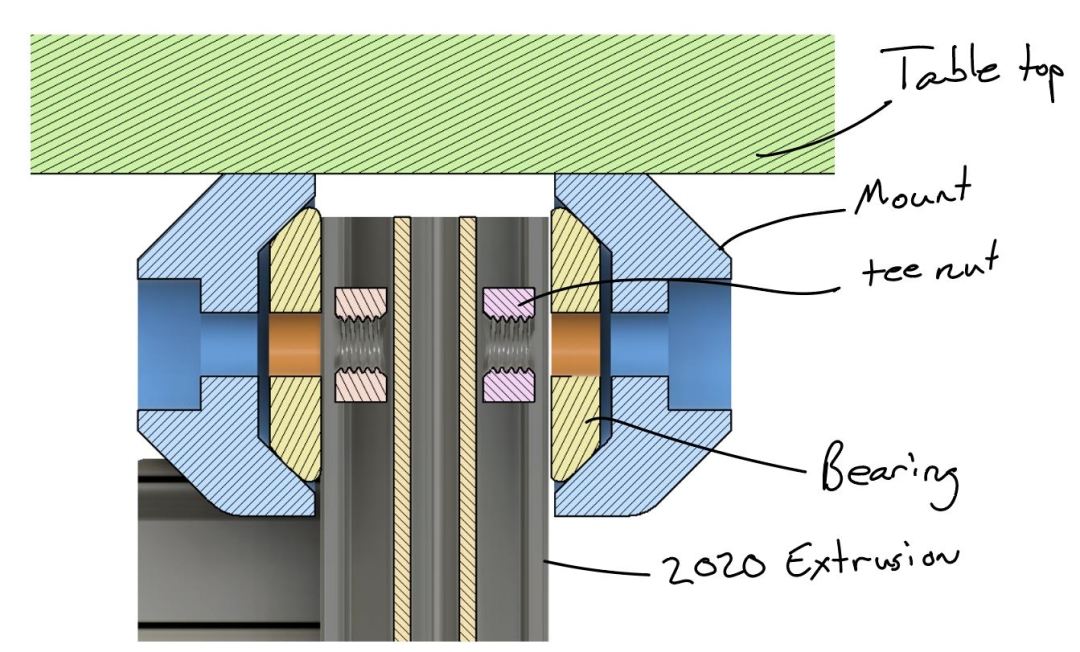

All of these pivots have the same basic design for the pivot mechanism. The annotated (at least technically, if you can read my hieroglyphs) cross section below shows the basics.

There are three main parts to the assembly, the Pivot Ball and then two Hinge Bodies. By relying on the ball pivot within the load path, the pivot can operate more smoothly even with misalignment in the 'bearing'. Although the ball pivot does smooth the movement, I wouldn't really recommend these for any sort of regular-use hinge application. While a shoulder bolt could be swapped in place of the M5x25 to make this into a more proper hinge, it would require sliding friction between printed components. Should be fine for a hinge that is only going to see occasional use.

The main differences between the below are in the Hinge Bodies, with each having different attachments to the extrusion to enable different configurations.

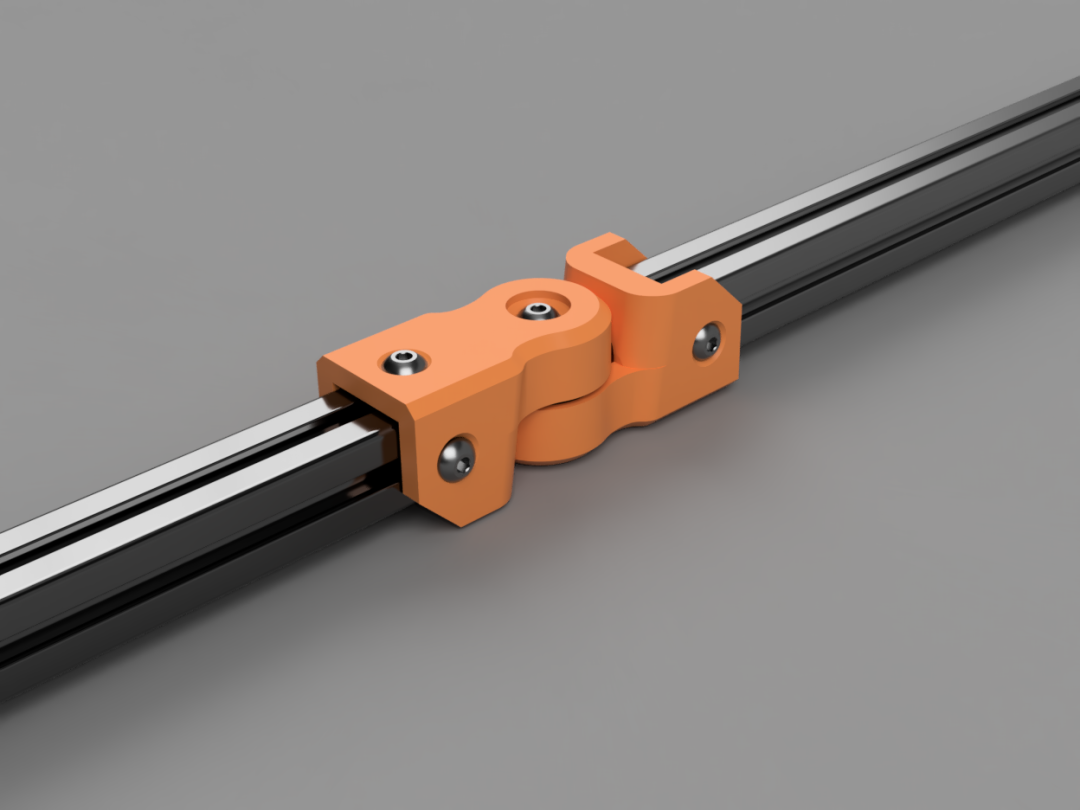

In-line - Single

|

|

This is an in-line pivot and is the simplest and most compact of these hinges (at least as of when I'm writing this). It has three fastening points on each hinge body, but all of them are in the 'end' location. So this would not be an idea choice for anything that's going to be cantilevered with any appreciable load on it. Works great for a static frame that needs to have some odd angles in it. If you don't want to use heat sets (but if not, you're really missing out :) ) you can also just print two of the 'BHCS' bodies, and use an M5x30 with a nut.

In the pictured build:

- Hinge bodies and PivotBall - Printed with 0.48 layers on 0.6 nozzle in Orange Overture PETG and Black Overture PETG

- Heat set insert - M5x6 - I've been using these, but any similar option should work.

- Fasteners - I pulled mine from this kit that I've rebought a few times now.

- M5x10 (Qty 6) - These are for the attachments to the 2020

- M5x25 (Qty 1) - For through the pivot

- 2020 Extrusion - I've bought many brands and most are all pretty much the same. I've rebought this brand several times and been happy with the price/ft compared to the others, but I know that also can change any given day....yea Amazon :)

- T-nuts - I don't buy anything other than this style of T-Nut anymore. Can be dropped in, they stay put, they are available in different fastener size options....I just love them...¯\_(ツ)_/¯ hey, we've all got our thing

90 Degree

|

|

This one is for a hinge/pivot where the extrusion being pivoted is 'normal' to the one it is being attached to...didn't make sense? Look at the picture and you figure it out! :)

The parts and materials are all the same as the ones listed about, with the exception that the printable files can be found here on Printables.

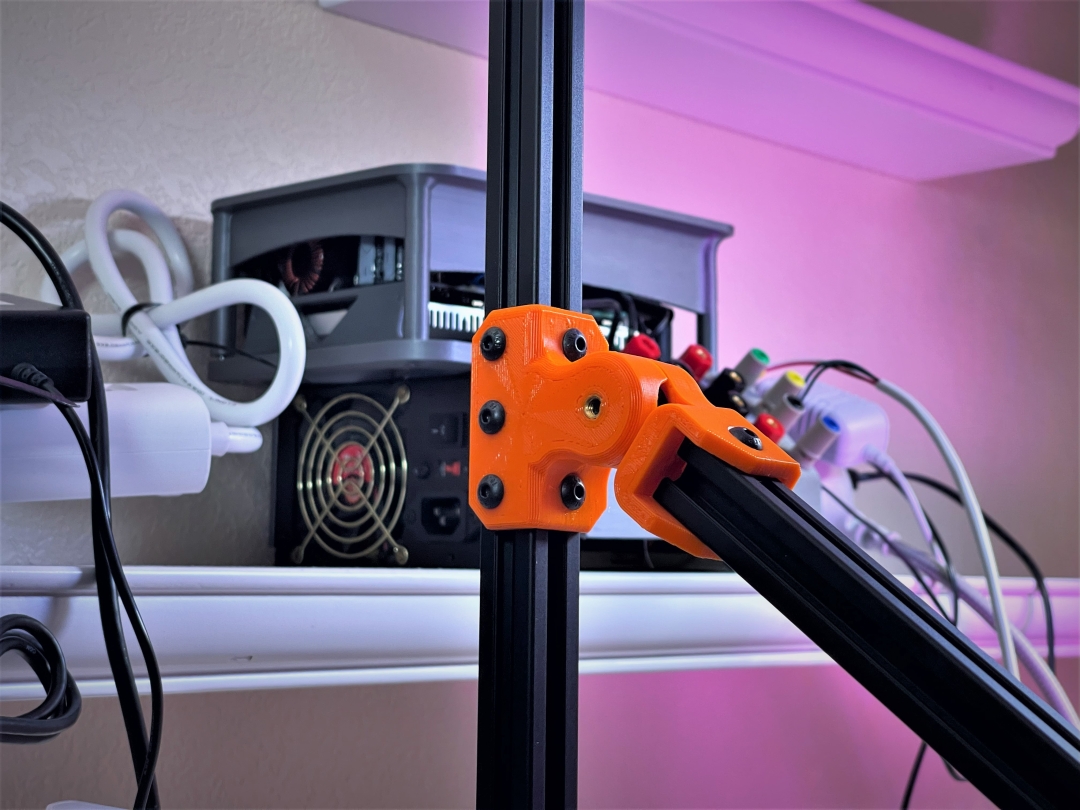

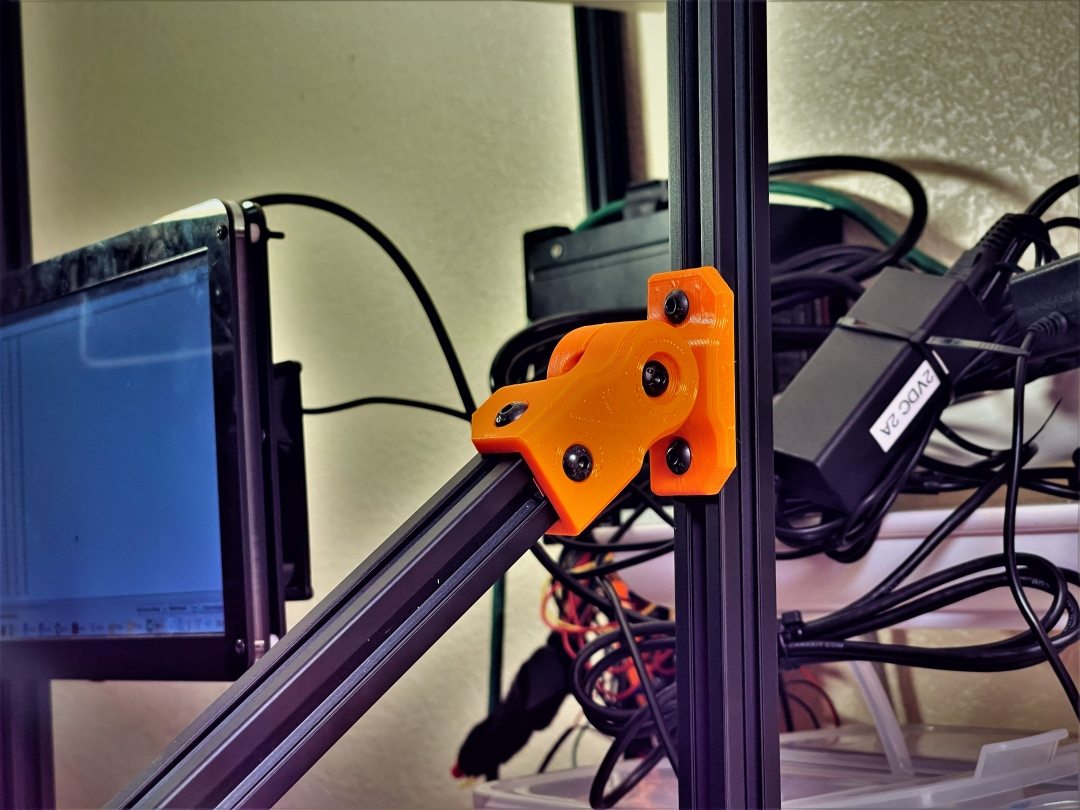

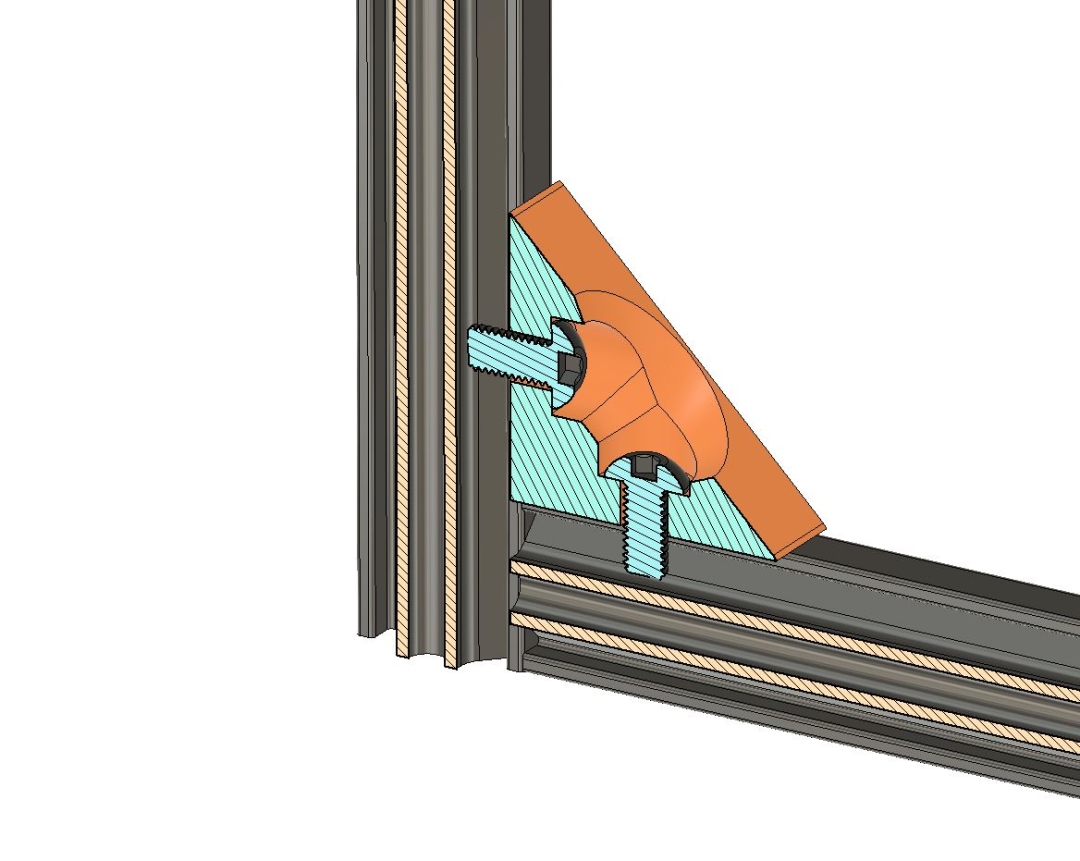

Midspan

|

|

A pivot/hinge for 2020 aluminum extrusion. The hinge is made up of three printed parts, none of which should need any supports, brims, etc. I designed it for introducing odd angles into 2020 extrusion frames. I've now made a few different variants on this pivot, this one is intended for when one frame member needs to come in at an angle, midspan of another member.

I printed mine from PETG on a 0.6mm nozzle and it takes about 2 hours for the set.

Hardware:

- HingeBody_Midspan.stl, HingeBody_BHCS.stl, and PivotBall.stl - Parts to print. I printed mine in both Orange and Black Overture PETG.

- m5x6 Heat Set insert - I used one of the 6mm lengths from this kit, but anything under 7mm length should be fine.

- m5x10 BHCS and m5 t nuts

Folding Table Hinge

Printables | Thingiverse

Details on the folding table hinge can be found here

|

|

90 Deg Elbow

|

|

Just a little 90 degree elbow. Configured for at least two M5x10 fasteners per extrusion (can be three on the long side if you also add the one in the corner, as shown in the images.)

Each prints in under a half an hour (with my settings) and shouldn't need any brims, supports, etc.

Hardware pictured:

- Corner_90.stl - I printed mine from Blue Overture PETG. Full print settings in the 3mf file available on Printables et al.

- M5x10 BHCS - The 'meat' of the plastic at the bolt interfaces is 5mm thick and the holes are nominally 5.5mm diameter...deviate as you wish :)

- M5 t-nuts - I love the little spring-loaded t-nuts that are drop in (don't have to be slid in from the end) and preloaded to stay in place.

Tees

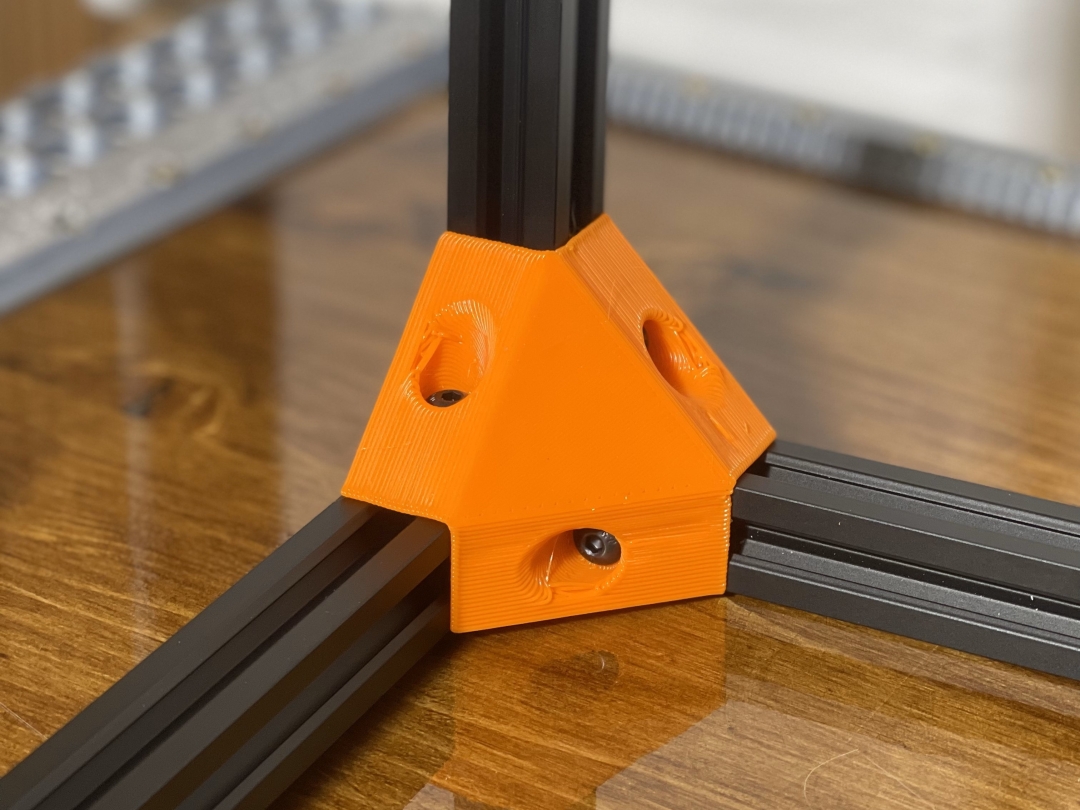

3-way Tee

|

|

A 3-way tee for 2020 aluminum t-slot extrusions. Provides a sturdy, square corner for frames and the like.

Each one takes about 30 min with my slice settings (0.48 layers on a 0.6 nozzle, full settings in 3mf file on Printables)

Pictured hardware

- Tee_3-way.stl - Pictured one was printed in Orange Overture PETG.

- M5x10 BHCS - Should work fine with any M5x10, but I sized it with BHCS in mind.

- 2020 Extrusion - I've bought many brands and most are all pretty much the same. I've rebought this brand several times and been happy with the price/ft compared to the others, but I know that also can change any given day....yea Amazon :)

- T-nuts - I don't buy anything other than this style of T-Nut anymore. Can be dropped in, they stay put, they are available in different fastener size options....I just love them...¯\_(ツ)_/¯ hey, we've all got our thing

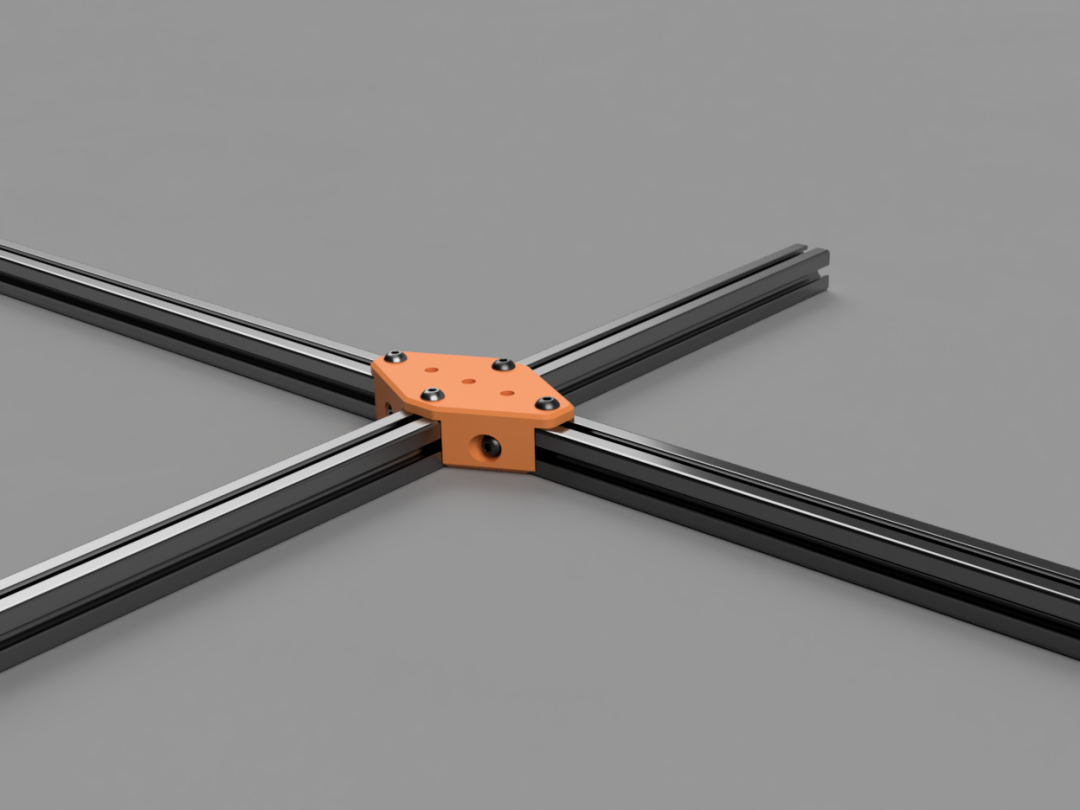

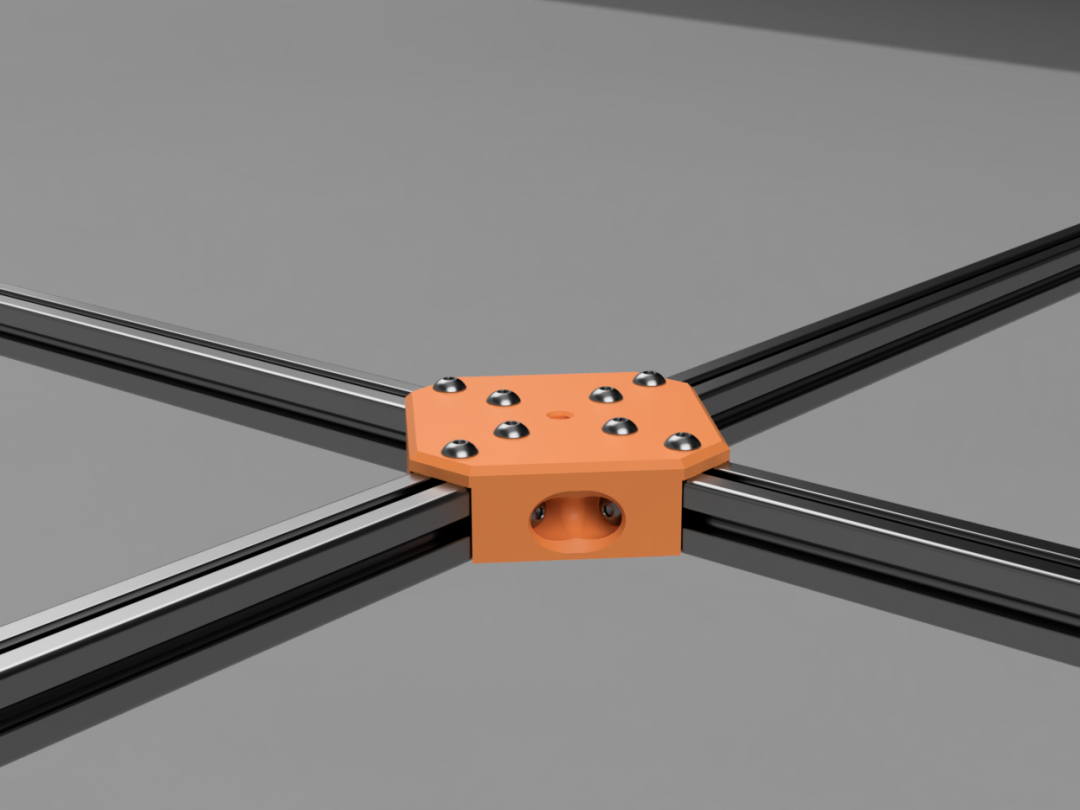

4-way Tee

|

|

A 4-way tee for 2020 aluminum t-slot extrusions. Provides a sturdy, square corner for frames and the like.

Each one takes about an hour with my slice settings (0.48 layers on a 0.6 nozzle, full settings in 3mf file on Printables)

Pictured hardware

- Tee_3-way.stl - Pictured one was printed in Orange Overture PETG.

- M5x10 BHCS - Should work fine with any M5x10, but I sized it with BHCS in mind.

- 2020 Extrusion - I've bought many brands and most are all pretty much the same. I've rebought this brand several times and been happy with the price/ft compared to the others, but I know that also can change any given day....yea Amazon :)

- T-nuts - I don't buy anything other than this style of T-Nut anymore. Can be dropped in, they stay put, they are available in different fastener size options....I just love them...¯\_(ツ)_/¯ hey, we've all got our thing

4-way Tee - Full

A 4-way tee for 2020 aluminum t-slot extrusions. Provides sturdy corner for bringing 4 extrusions to a square corner.

Each one takes about an hour and a half with my slice settings (0.48 layers on a 0.6 nozzle, full settings in the attached 3mf file.)

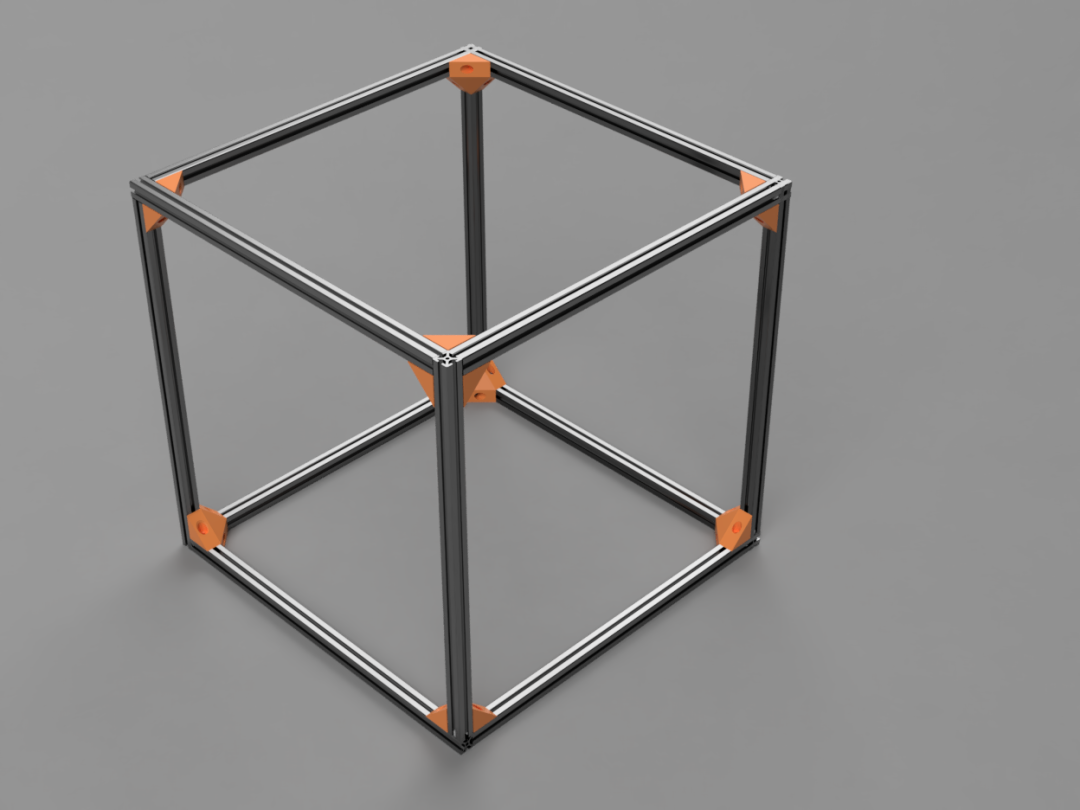

Corners

Square Corner

|

|

Designed to fasten 2020 Aluminum Extrusions to make cubes with flush edges. Not intended to be particularly high load capacity, but I've built quite a few frames from this general design, and they are working just fine for my needs! Holes are designed for M5x16 BHCS fasteners, but slightly shorter (maybe down to 12mm...maybe...?) should work.

Mine have printed fine without supports, brims, etc.

I printed these in Orange Overture PETG with 0.48 layers on a 0.6mm Revo nozzle.

Other Stuff

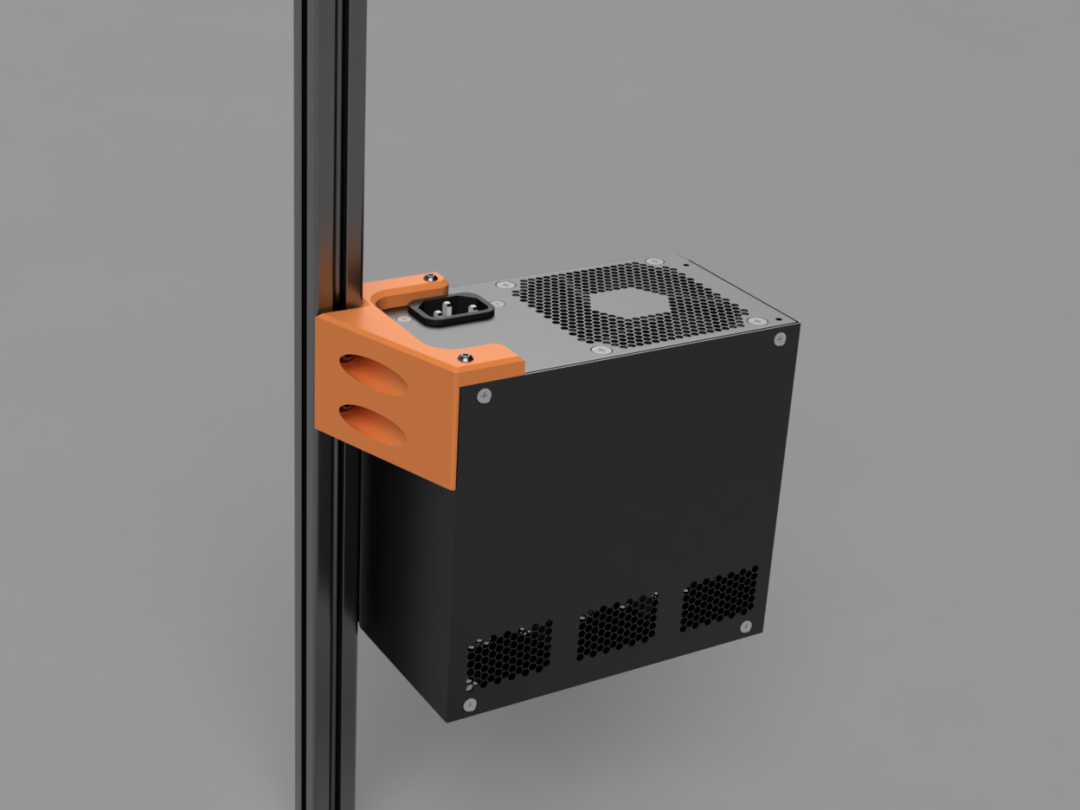

PSU to 2020 Mount

|

|

A bracket for attaching an ATX (regular ol' computer power supply) to 2020 extrusion, but please note, although I show it suspended in a vertical orientation with just this bracket, I wouldn't recommend it! This was designed, and is currently used, with an additional support below the supply. This bracket will support the weight of the supply by itself, but my concern is whether that would stay stable long term, after exposure to heat from the PSU.

Should print fine without supports, brims, etc.

I printed the one shown with 0.48mm layers out of Black Overture PETG.

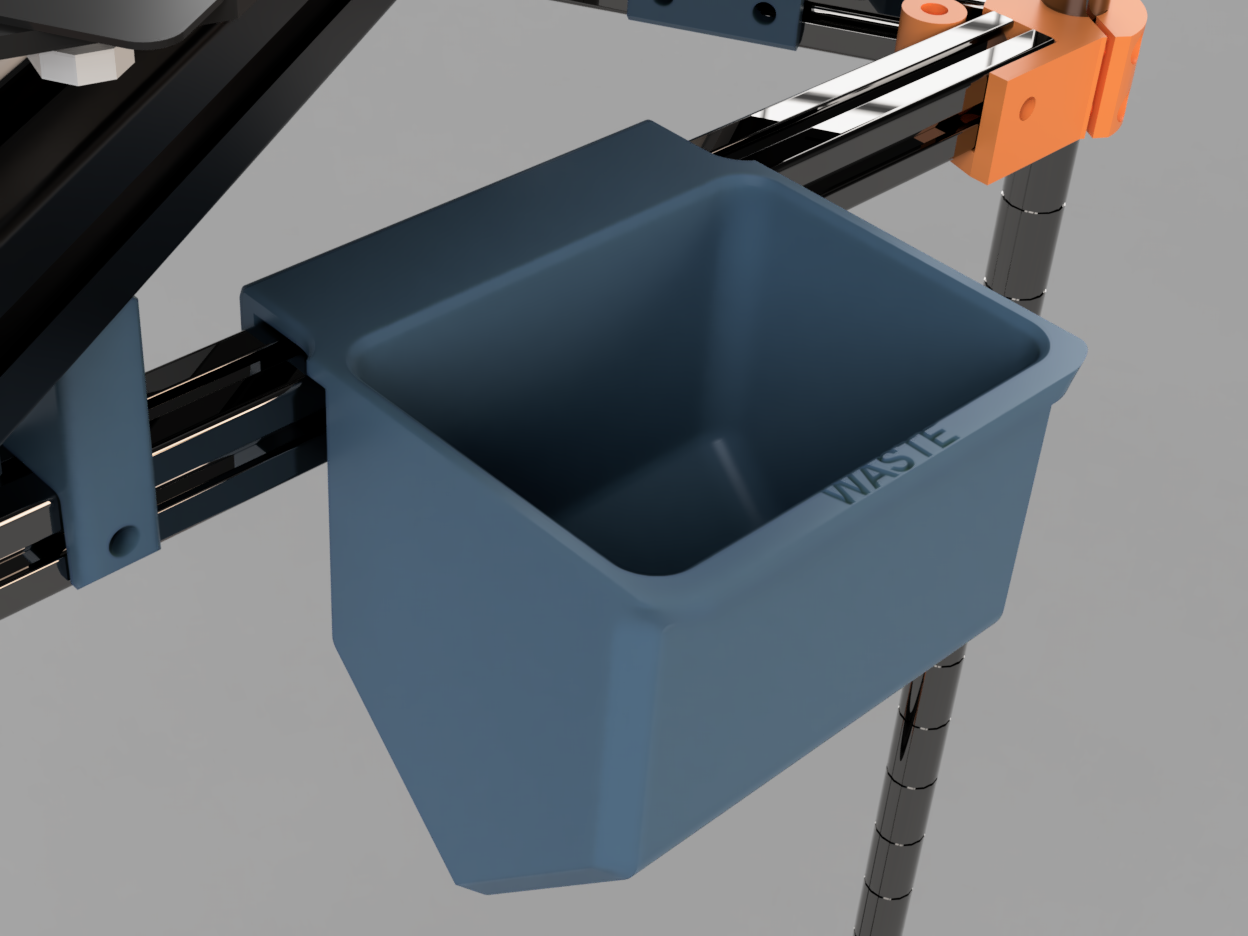

Waste Bin

|

|

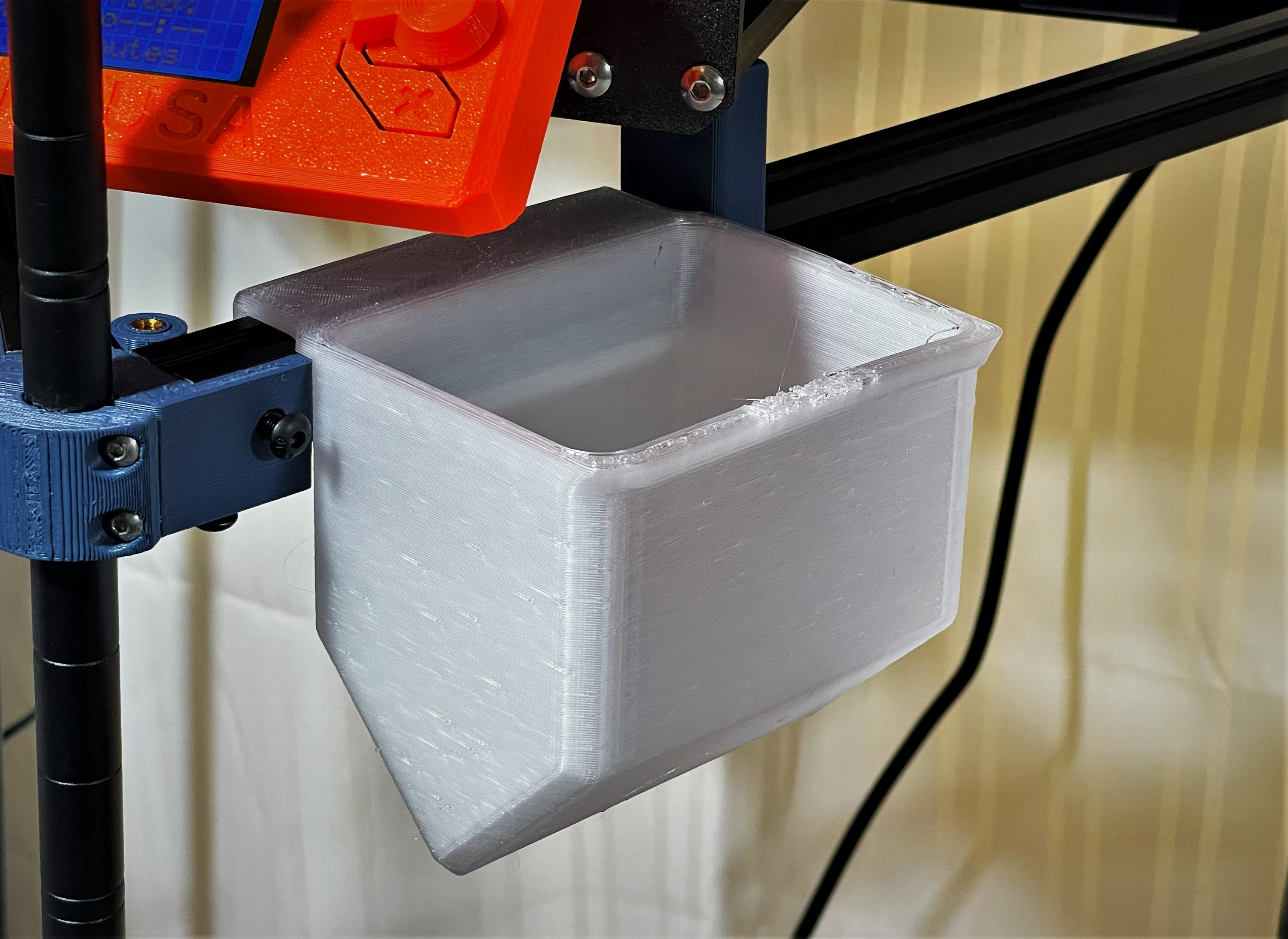

A simple waste bin that hangs from 2020 extrusion, intended as a convenient spot for tossing purge lines, brims, and the other assorted scraps/trash that accompany extrusion printing.

Prints without supports and took about 3.5 hours with the attached slicer config (0.6 nozzle), but I should point out that the lettering on my print came outa little lackluster.

I printed mine in Overture clear PETG

Simple Hook

A simple, quick-printing hook for hanging accessories and such from 2020 extrusions. I'm using several of them quite happily on my i3 printer tower.