System-level Projects

- Details

- Parent Category: System-level Projects

- Category: Project Fireplace

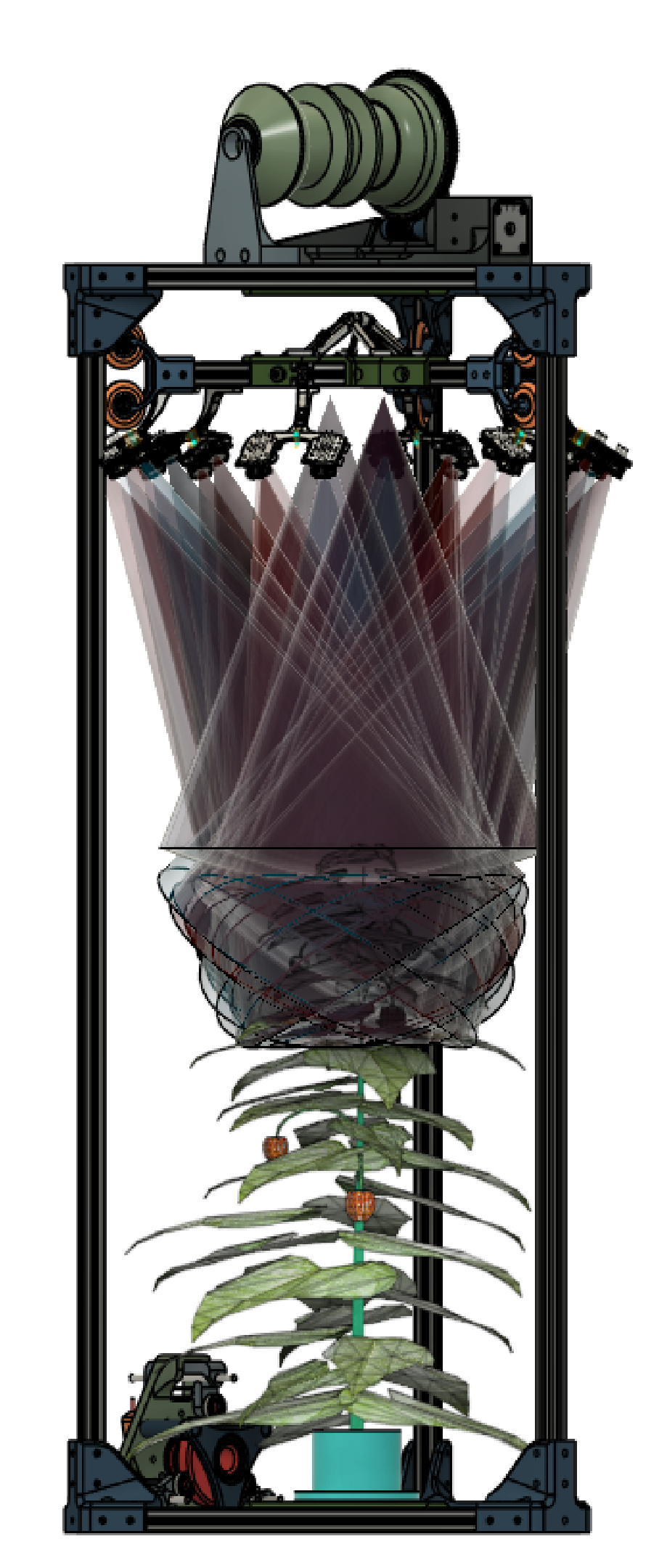

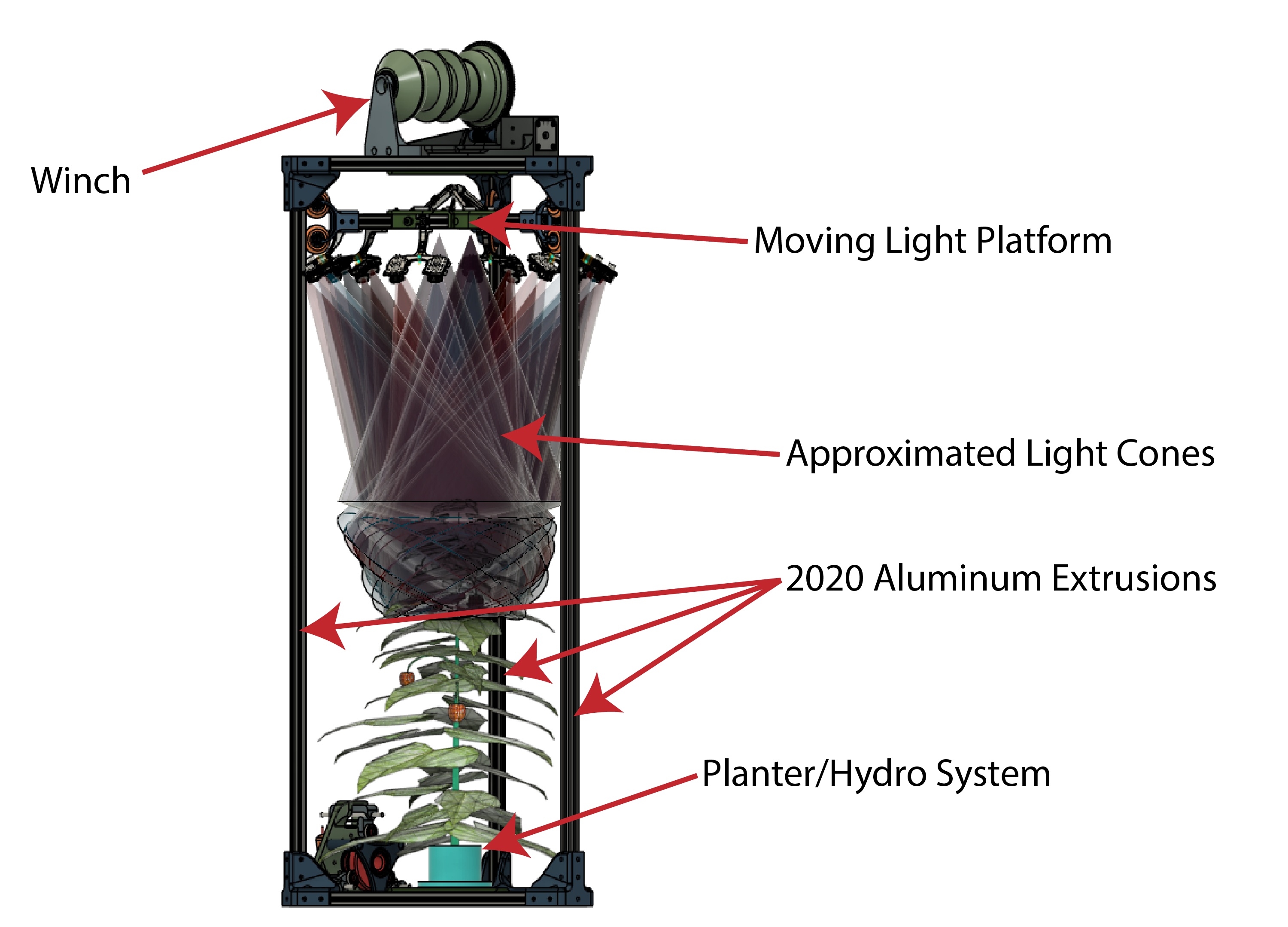

Continuing work on the Project Fireplace pepper growing system (aka, the instrumented produce-growing system(s) that will live above the fireplace). I decided the next subsystem to tackle for this build is the frame and structure for the lighting.

The main challenge for this subsystem is the need to be able to raise and lower the lighting components relative to the plant. This is important for both reducing the wasted light, but also for maintaining lighting intensity when plants are in early growth stages.

To be fair, I could kick the can on this problem, and instead try to accomplish this by moving the hydro system to move the plant instead....but as much as I love an opportunity to procastinate, that sounds like a real pain in the ass. So light moving it is.

Design Overview

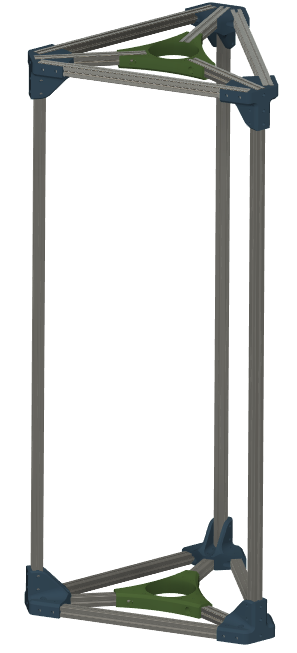

The main structure of the system will be provided by some 2020 aluminum extrusions connected by 3d printed (FDM from PETG) brackets. On top of that structure sits an admittedly oversized winch. The winch raises and lowers the moving platform that the LED clusters will be attached to.

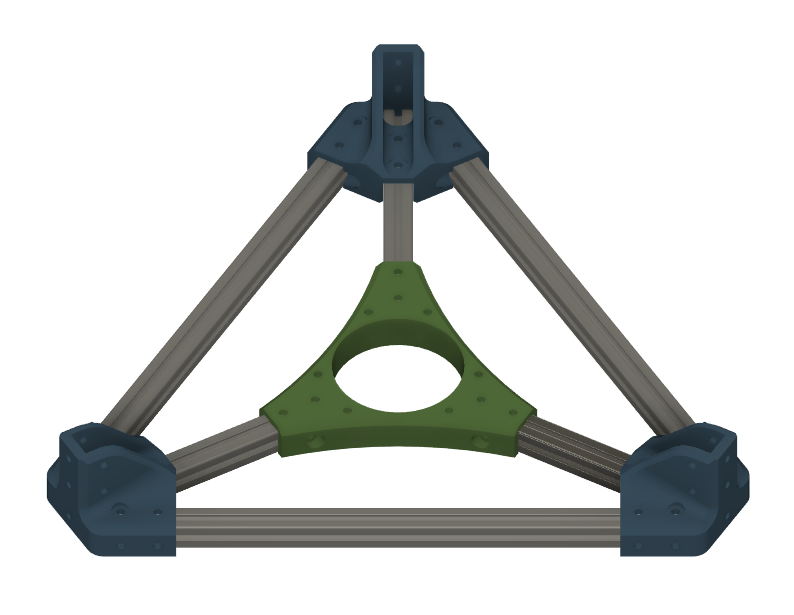

Taking a closer look at each of those, let's start with the base and top frame assemblies. Both are the same construction, shown in the image from the model shown below.

It is made up of 6 pieces of 2020, connected together with four PETG brackets. The brackets in the center provide structure and attach points for 1) the planter/hydro system on the bottom and 2) the lift system on the top. The top and bottom assemblies are connected together with a set of vertical 2020 extrusions. The length of these extrusions sets the total height of the system. I went with 1m lengths.

WORK IN PROGRESS - This article is a work in progress. If there are specific aspects of the project you're eager to know more about, feel free to drop a comment here or on my socials and I'll prioritize getting that part added!

- Details

- Parent Category: System-level Projects

- Category: Project Fireplace

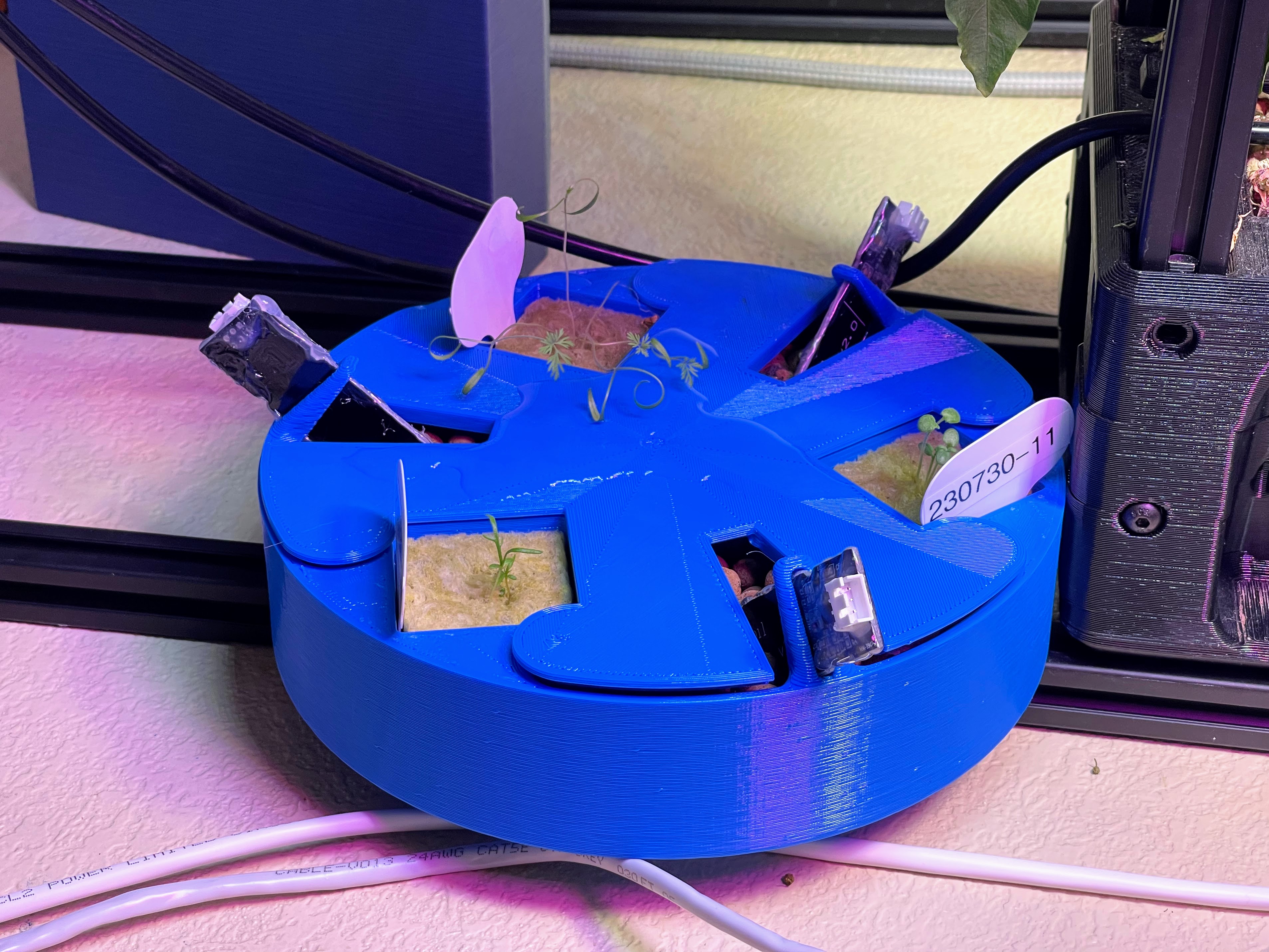

Herb Planter - 3 position

Design goals

- Provide at least 3 locations for 1.5" Rockwool cubes

- Fit within Prusa Mk3s build plate (actually limited allowable box to 200mmx200mm in XY

- Provide secure mount point to 2020 aluminum extrusion

- Integrated mounting/guiding of at least two moisture sensors.

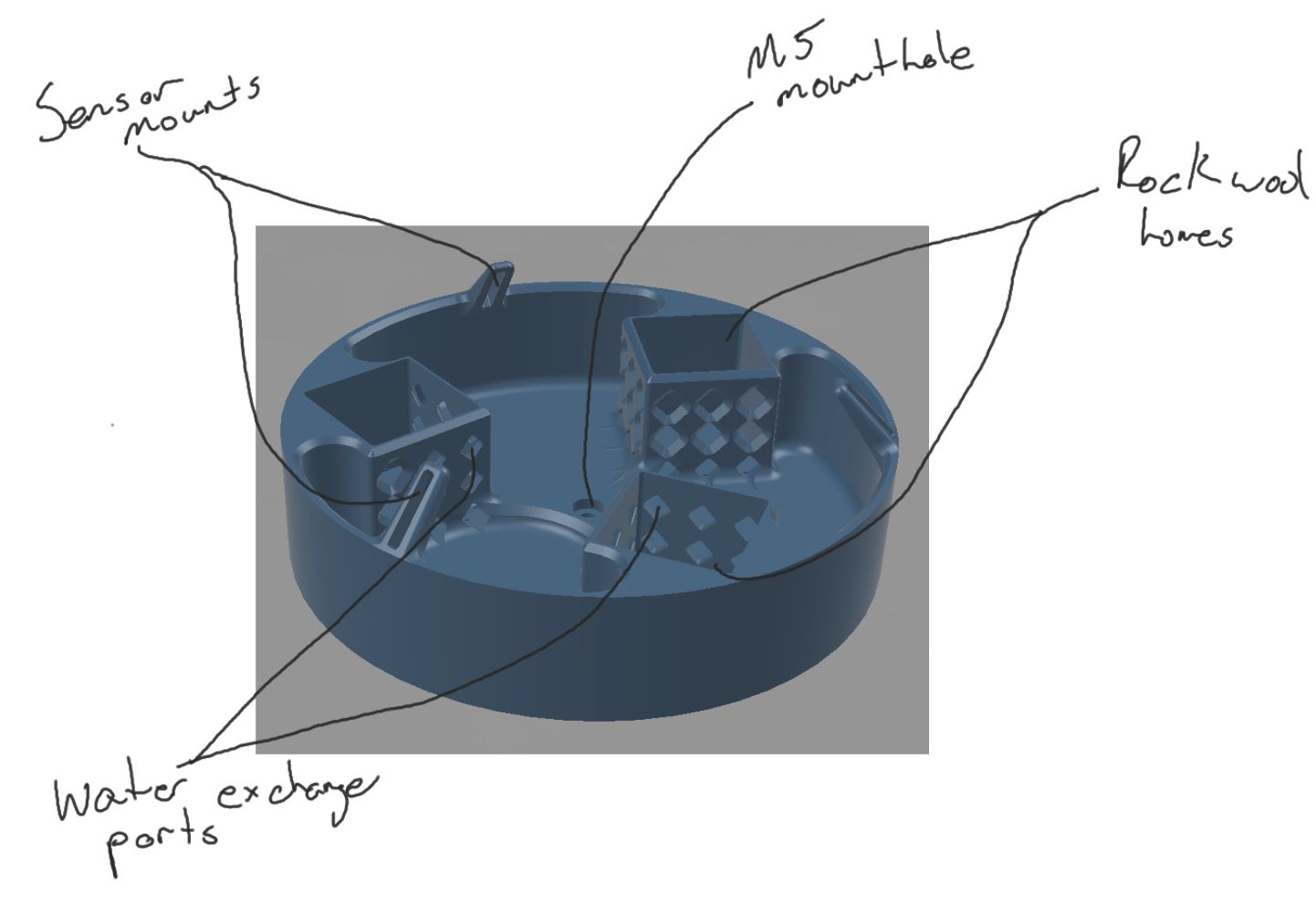

The design concept I settled on is a circular footprint with the three cube locations evenly spaced at 120 degrees. To help improve moisture retention, I decided to have the center region open, and filled with expanded clay pellets (aka hydroton). So the inner walls of the cube holders are 'vented' with relatively large diamond-shaped openings in the hopes of getting intimate contact between the rockwool and the hydroton.

The planter is secured to 2020 extrusion via a single M5 mount hole in the center of the part. The intent (and implementation) is to secure the planter in location, and then fill/seal it with hot glue prior to filling with hydroton. This planter is intended only for use in a flat orientation, and no real dynamic loads (other than some light wind load). So this single M5 should be plenty to handle any asymmetric loading caused by different plant sizes at this size.

I have used these capacitive soil moisture sensors for previous builds using hyrdoton as the grow medium, so I know they can give a usable signal for closed-loop control. In my initial tests, I wasn't sure if it would work since there are air gaps caused by the spherical pellets limited packing factor. That being said, I'd LOVE to find a better, more scalable option for moisture sensing. The linked sensors are fine, but each needs to be sealed (the driver circuit is fully exposed, and the sides of the boards are raw-cut PCB, which will uptake water over time) and their form factor isn't always ideal. But I digress...

To locate the sensors within the assembly, I added some slotted risers on the sides. The slots are oriented at 45 degrees, partially to make them printable without supports, but primarily because the 'nose' of the sensor is a right angle. So by having the slot at 45, the edge of the sensor should sit flush against the base of the planter. Between the slot and the planter base, this provides a reasonably repeatable constraint for the sensor.

The reason I care about having the positioning of the sensor somewhat repeatable/consistent within the planter, is because the moisture readings are very sensitive to their depth within the medium. So the goal with this constraint scheme is 1) to try to reduce sensor drift by limiting physical movement within the medium, and 2) to try to improve the interchangeability of the sensors and be able to compare channels directly...This second goal is less of a driver, since my experience with these sensors is that there are MANY factors that contribute to the sensors response curve (another reason I'd really like to find an alternative tech for this.)

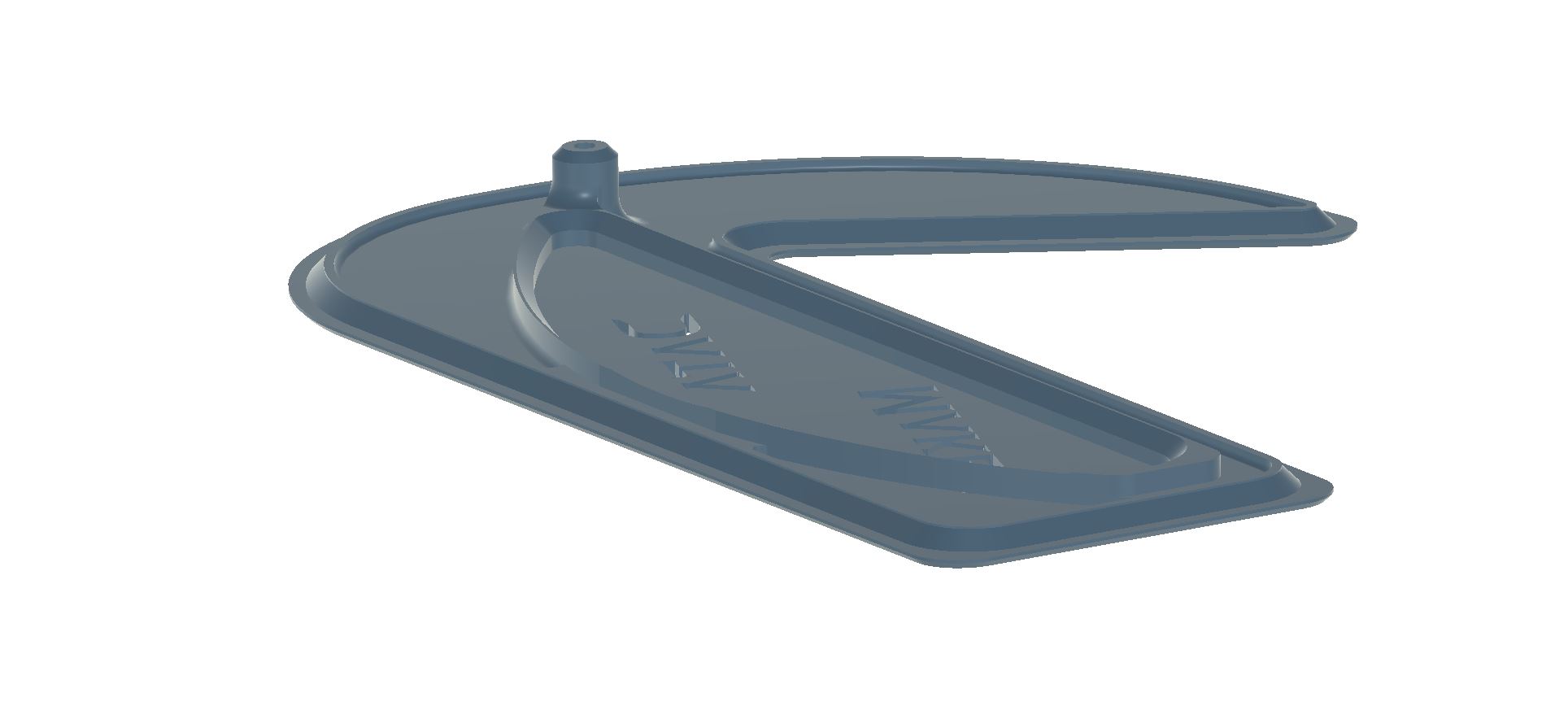

And finally, I added a lid to help reduce the rate of water loss and to reduce the growth of unwanted extras in my grow medium.

The Build

The build on this one is pretty straight forward, I suppose, but here goes :)

BOM:

- Printed Parts - I printed mine from Blue Overture PETG

- Planter Body (aka "Circular_3loc_1p5cube.stl")

- Lid (aka "Lid.stl" ¯\_(ツ)_/¯)

- COTS

- (Qty 3) 1.5" Rockwool cubes

- Expanded clay pellets

- (Qty 3 or less) Moisture sensors

- M5 fastener of your choice, if you're mounting it to something (could also just seal up the hole and have it lay flat on a surface ifn ya want)

- Hot glue or other sealing material of your choice (just make sure you're ok with that sealant coming into contact with your food...or at least the food of your food, but transitive property, ya know)

When printing the Planter, I'd recommend at least 3 perimeters to improve water retention.

My order of operations was:

- Secure planter to frame with M5 fastener in a t-nut. Then seal up counterbore with hot glue.

- Insert rockwool cubes with seedlings (would presumably be easy enough to set these up as seed starters, but I started mine separately.)

- Seal up soil moisture sensors and then put them in their respective homes.

- Soak, drain, and rinse clay pellets, then add to planter.

- Add lid

However, for future assemblies, I'll likely change that order to 1, 3, 4, 5, 2. There is no reason the plants can't be put in last, and this reduces the risk of accidental damage when putting on the lid.

The sensor wires run to a small board to consolidate them down to a single, Cat5 cable that then heads over to the Data Maker Electronics Enclosure.

Thoughts/Notes

One major omission I've discovered was on the irrigation supply side...guess I got stuck on the 'feedback' side of things, and kind of forgot the other, somewhat crucial side of a closed-loop system :) Luckily, I think this omission may be something I can integrate well into a revision of just the lid.

Although I didn't want to give up the 'wet volume', I think if I do a full rev of this planter (although I don't currently plan to) and in future, related builds I will go with fastening points outside of the sealed region. It hasn't been an issue for me yet, but just in assembling them I was imaging me frustrated at not being able to easily reposition the planters on their rails without having to empty and dry out the clay pellets.

- Details

- Parent Category: System-level Projects

- Category: Project Fireplace

The goal for this build was for a fairly simple electronics enclosure. The "requirements" were:

- Provide space for 'mounting' (just using the adhesive backing) for a medium solderless breadboard

- Interior space must accommodate a USB connection to an Arduino Nano at one end of the breadboard

- At least two mount points to 2020 extrusion (or comparable M5 mount with flexible spacing)

- Integrated strain relief

- A secure form of strain relief with at least two separate 'channels'

- Prefer a 'permanent' option over integrated zip tie attach points, but not required

And here is what I came up with:

|

|

There is an enclosed(ish) volume that is spaced on three sides for just a conservative clearance fit, and the fourth side opens up to provide something of a conduit for the cabling. The conduit directs the cables around a 180 degree bend and then out one of three ports.

In line with each of the ports are the strain relief elements. Each strain relief hold down is secured with three, M3 fasteners....yeah....quite overkill, but I was sort of locked in on the nested aesthetic they have goin on ¯\_(ツ)_/¯. Under each hold down is a recess intended for a strip of adhesive-backed foam. This allows for a rigid hold down, and firm strain relief, but without over-constraining the cables.

The lid is secured with a single M3...yeah, was overly conservative here, after over-doing it on the strain reliefs. My bad. I added some stiffening supports on the back side of the lid, shown in the image below. It works well enough that I don't have any intentions of revising the assembly to add a second fastener point, but a second attachment point down at the bottom (assuming the orientation shown in the above pictures) would slightly improve the 'fit and finish' for the seams on the bottom side.

Parts List:

- Printed Parts - For the pictured build, I printed all of the below from Blue Overture PETG

- (1) Enclosure.stl

- (1) Lid.stl

- (3) CableHolddown.stl

- COTS

- 1/2"x1/4" Weather stripping foam - Each recess is 75mm (~3") long. So these rolls are definitely more than needed for just this project. But I find having the stuff around to be handy :)

- (9) M3x16 BHCS - The fastener only has to actually extend 10mm (nominally) through the hold down, so shorter fasteners should be fine, but I find that going a bit longer helps keep the wires where I want them as I'm securing the hold down.

- (1) M3x10 BHCS - For holding down the lid. Goes through 5mm of material.

- (10) M3x6 Heat sets - One for each hold down mount point and one for the lid.

If you're interested in the bits inside the box, or if you have any questions, let me know in the comments!