The goal for this build was for a fairly simple electronics enclosure. The "requirements" were:

- Provide space for 'mounting' (just using the adhesive backing) for a medium solderless breadboard

- Interior space must accommodate a USB connection to an Arduino Nano at one end of the breadboard

- At least two mount points to 2020 extrusion (or comparable M5 mount with flexible spacing)

- Integrated strain relief

- A secure form of strain relief with at least two separate 'channels'

- Prefer a 'permanent' option over integrated zip tie attach points, but not required

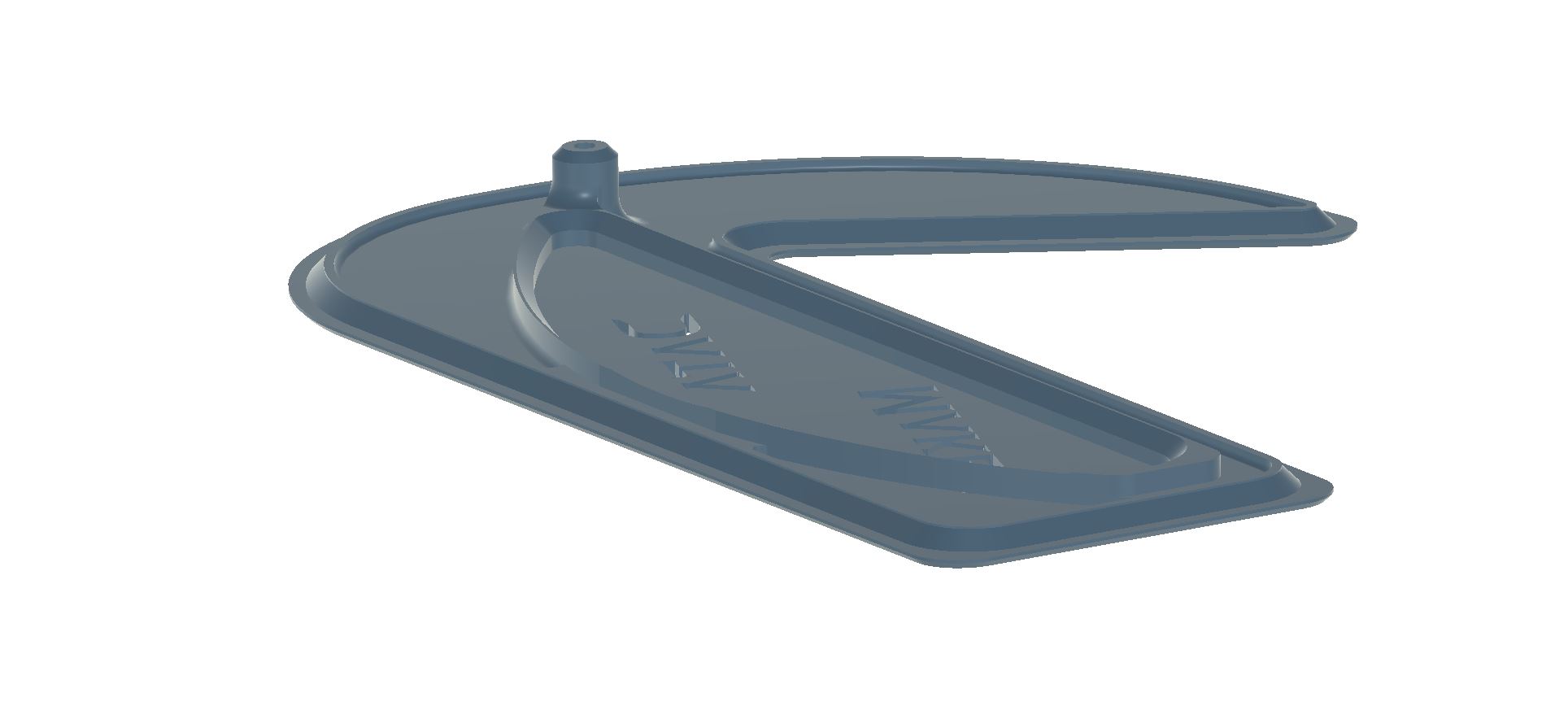

And here is what I came up with:

|

|

There is an enclosed(ish) volume that is spaced on three sides for just a conservative clearance fit, and the fourth side opens up to provide something of a conduit for the cabling. The conduit directs the cables around a 180 degree bend and then out one of three ports.

In line with each of the ports are the strain relief elements. Each strain relief hold down is secured with three, M3 fasteners....yeah....quite overkill, but I was sort of locked in on the nested aesthetic they have goin on ¯\_(ツ)_/¯. Under each hold down is a recess intended for a strip of adhesive-backed foam. This allows for a rigid hold down, and firm strain relief, but without over-constraining the cables.

The lid is secured with a single M3...yeah, was overly conservative here, after over-doing it on the strain reliefs. My bad. I added some stiffening supports on the back side of the lid, shown in the image below. It works well enough that I don't have any intentions of revising the assembly to add a second fastener point, but a second attachment point down at the bottom (assuming the orientation shown in the above pictures) would slightly improve the 'fit and finish' for the seams on the bottom side.

Parts List:

- Printed Parts - For the pictured build, I printed all of the below from Blue Overture PETG

- (1) Enclosure.stl

- (1) Lid.stl

- (3) CableHolddown.stl

- COTS

- 1/2"x1/4" Weather stripping foam - Each recess is 75mm (~3") long. So these rolls are definitely more than needed for just this project. But I find having the stuff around to be handy :)

- (9) M3x16 BHCS - The fastener only has to actually extend 10mm (nominally) through the hold down, so shorter fasteners should be fine, but I find that going a bit longer helps keep the wires where I want them as I'm securing the hold down.

- (1) M3x10 BHCS - For holding down the lid. Goes through 5mm of material.

- (10) M3x6 Heat sets - One for each hold down mount point and one for the lid.

If you're interested in the bits inside the box, or if you have any questions, let me know in the comments!