Valving

- Details

- Parent Category: Hydration and Hydroponics Projects

- Category: Valving

Overview

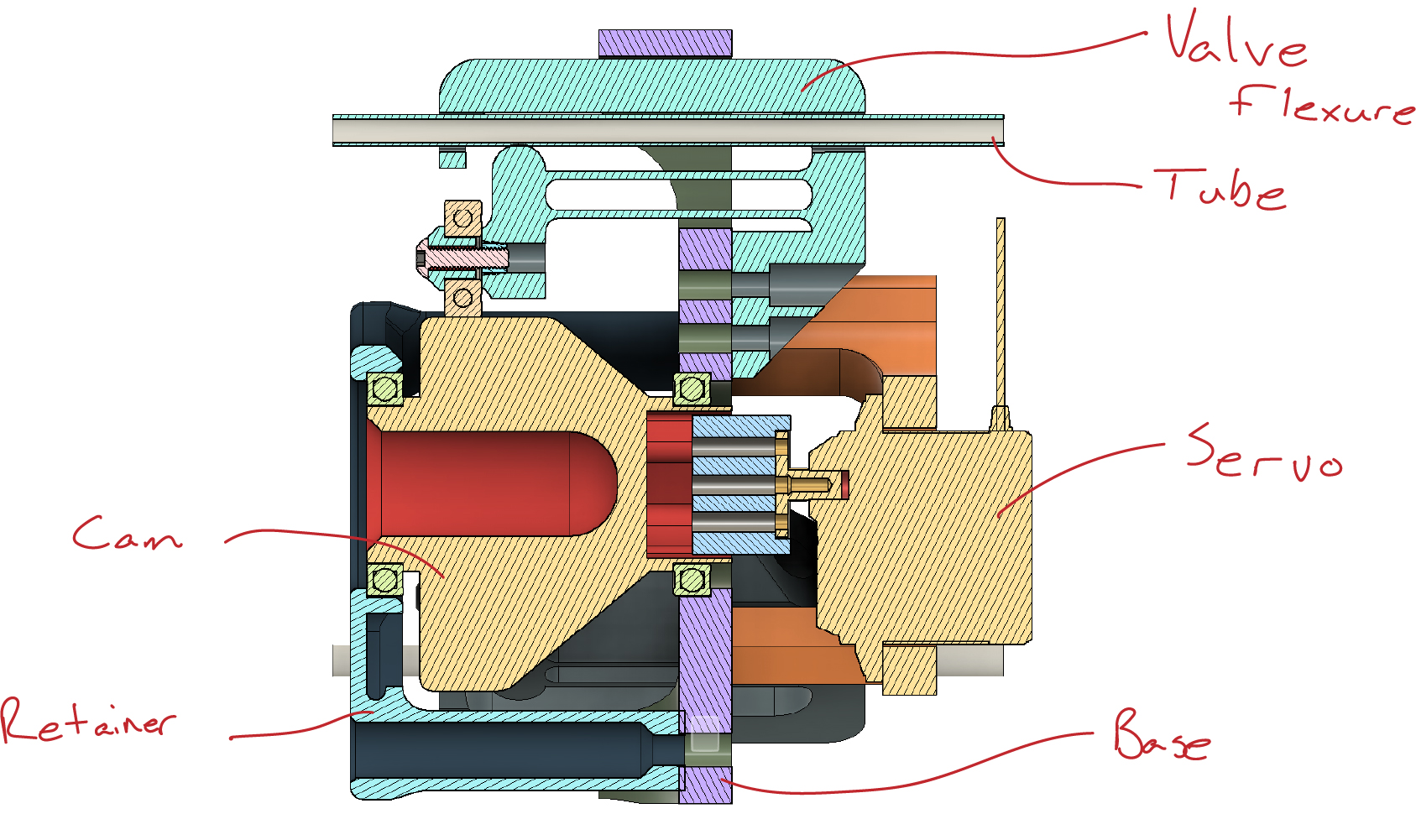

Design

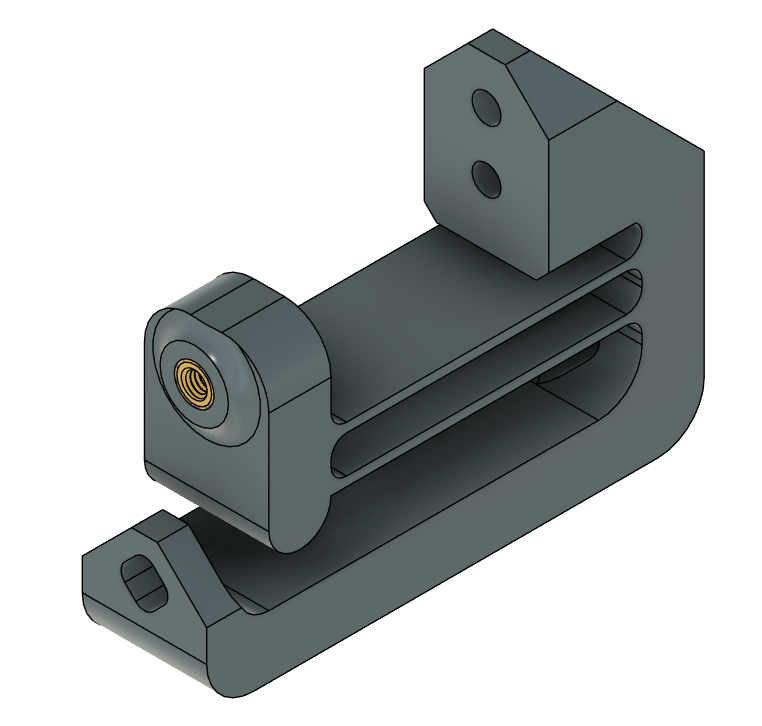

Valve Flexures

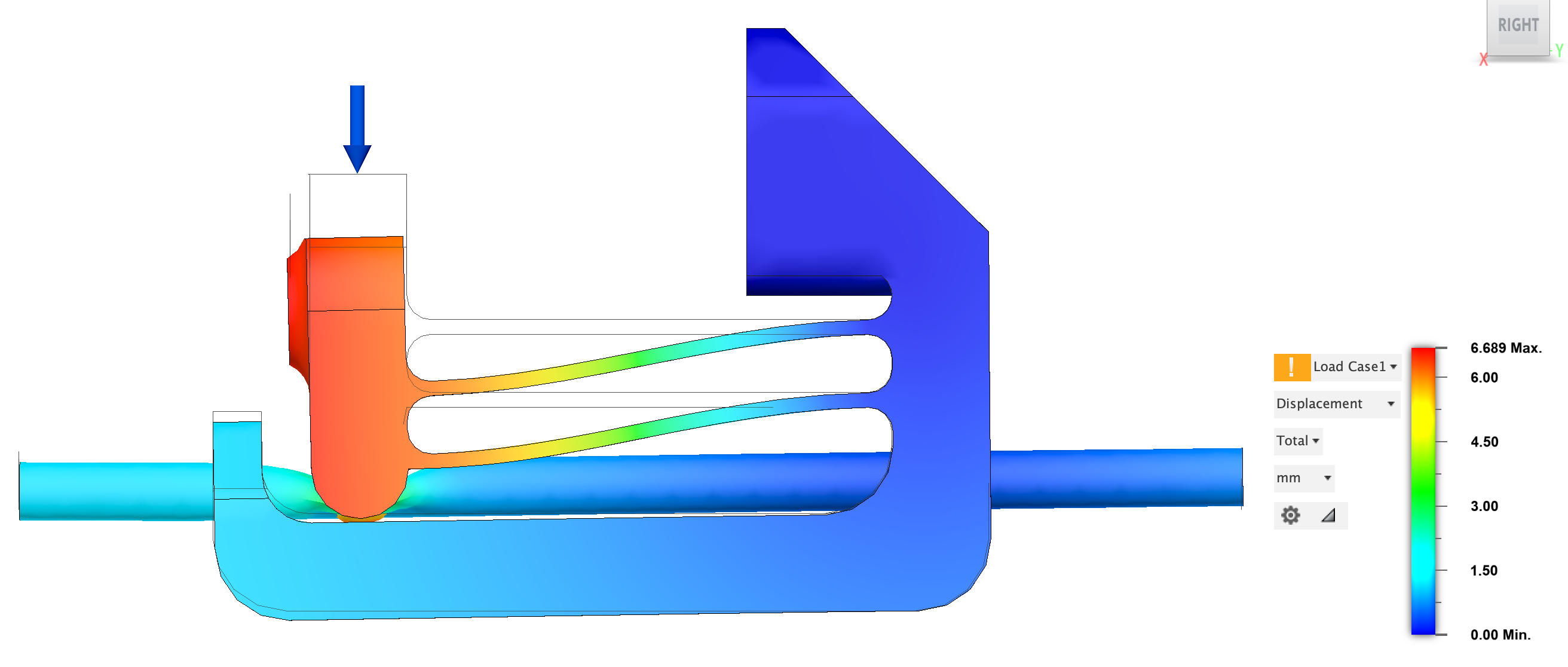

The image below shows one of the simulation results for the deflection of the valve. As the simulation shows, the “rigid” base element is expected to deflect a meaningful amount, but this is/was intentional. The idea behind allowing for this compliance was to reduce the sensitivity to tolerance stack up. The idea is that the nominal dimensioning is set to compress the tubing beyond what is actually needed by greater than the expected maximum deviation is stack up. As long as this base is substantially stiffer than the tubing, the vast majority of the deflection should be confined to the tubing until ‘lock up’ is achieved. Without compliance in the base, if the cam drove the follower beyond the lock up point of the tubing, the radial load would spike until compliance SOMEWHERE in the system accounts for this extra displacement....aka, something breaks. So, to avoid having the location of this compliance being selected for me, I opted to leave some compliance here in the rigid portion of the flexure.

In the initial testing, however, the actual relative displacement between the tubing and flexure base appears to show meaningfully more relative compliance in the flexure base than I expected. This wasn't a huge surprise, given how unpredictable printed polymers can be. So I just added some additional reinforcing to this section from the base that surrounds it in the assembly.

Build

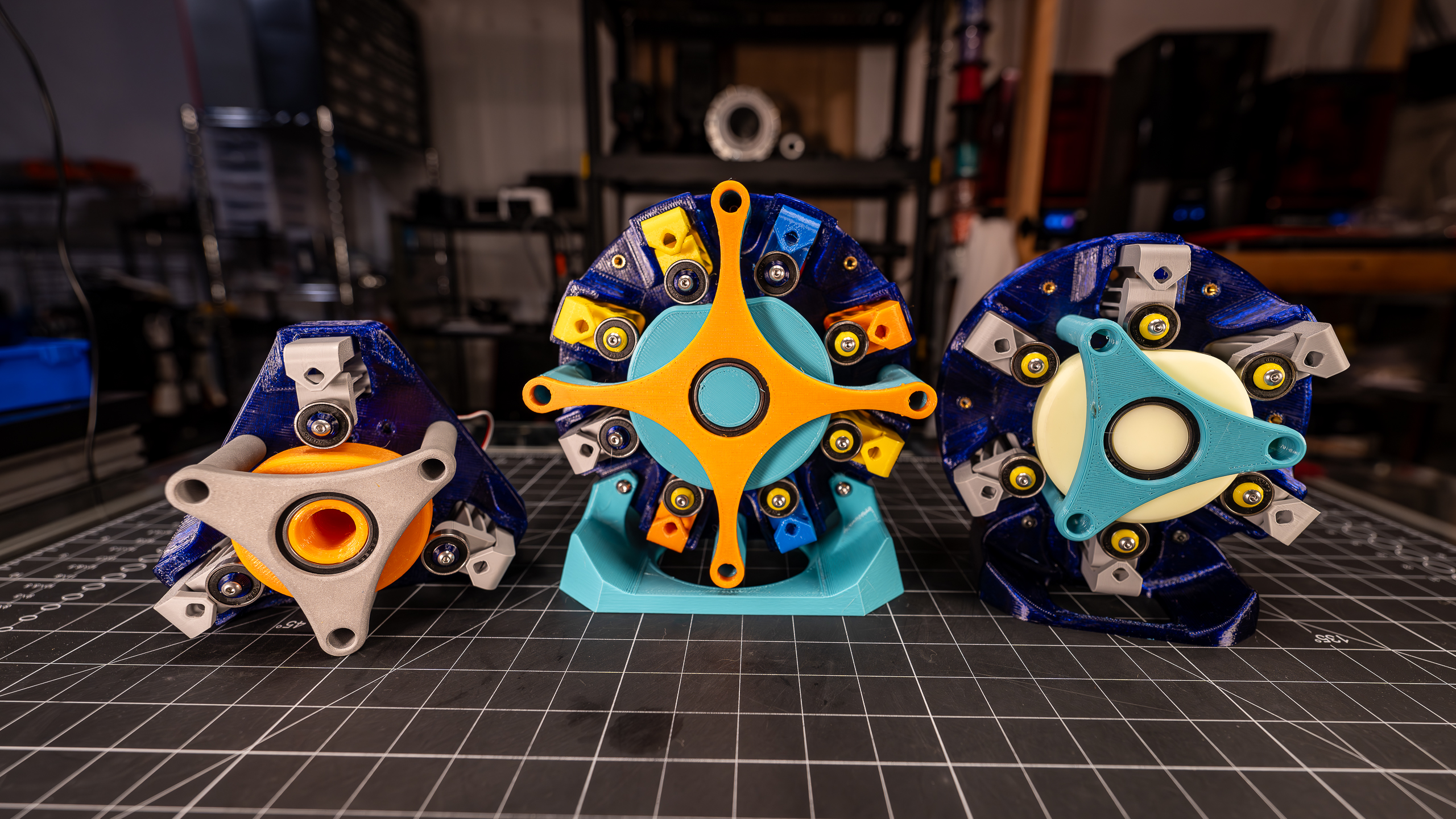

3 Channel

|

|

BOM

- Printed Parts

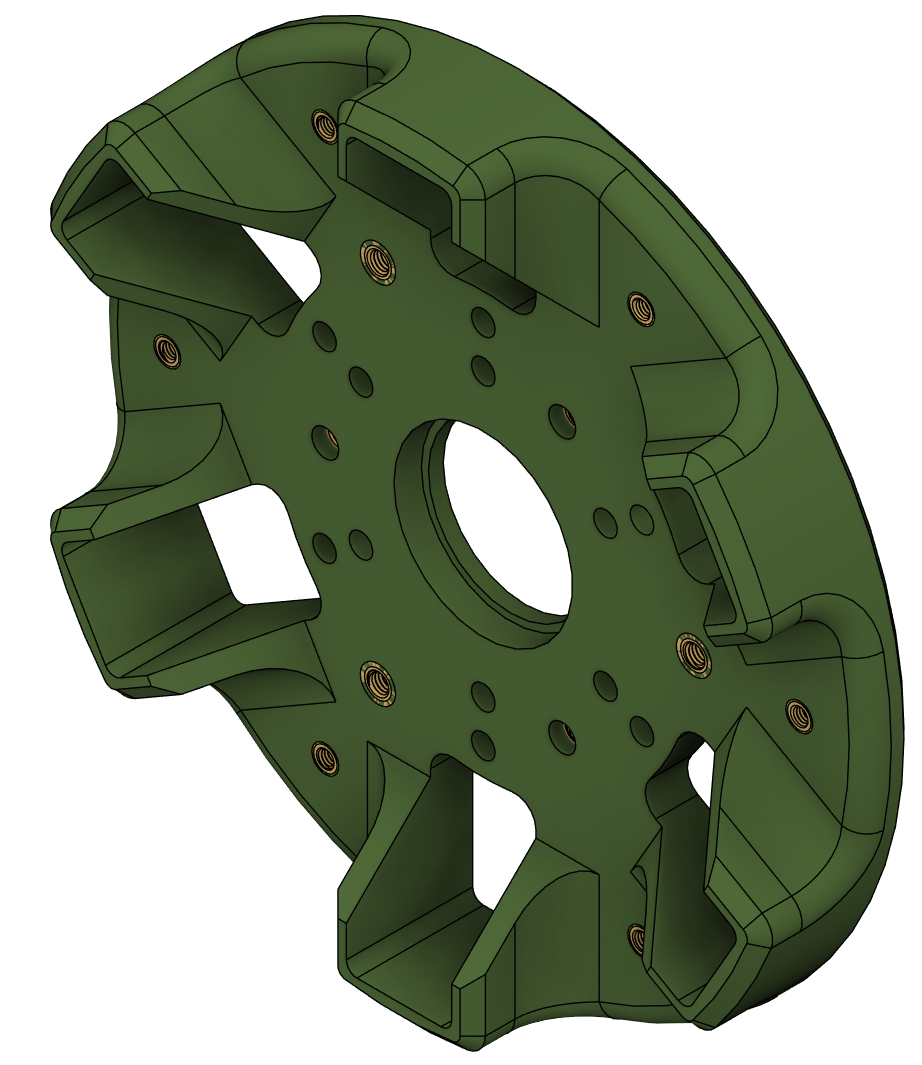

- (1) MainBody_3ch (aka "Base")

- (1) CamRetainer_3ch

- (1) Cam

- (1) Servo Mount A_3ch

- (1) Servo Mount B_3ch

- (1) Motor Coupler

- (3) Valve Flexure

- (3) Bearing Retainer

- COTs

- (17-19) M4 Heat set inserts - Min needed is 10, the 2 additional for extra mount points I included for symmetry/future uses.

- (3) M5 Heat set inserts

- (10) M4x12 BHCS fasteners - Six for attaching flexures to Base and four for attaching servo to Servo Mounts. The latter can be shortened to as short as 8mm.

- (3) M4x16 BHCS fasteners - For attaching roller bearings to flexures

- (4) M4x20 BHCS fasteners - For attaching Servo Mounts to Base. Should be ok anywhere from 18mm long to 22mm long.

- (3) M5x10 Flathead fasteners - For attaching Cam Retainer to Base. They don't need to be flatheads, that's just what I had, so what I used.

- (3-5) M3x18 BHCS fasteners - For attaching the Motor Coupler to the servo horn.

- (3) 608RS 8x22x7 Bearings - I bought this hundred pack since it makes the cost per bearing so damn lovely, but you obviously don't need nearly this many. This size bearing is the same as move roller skate bearings...FYI

- (2) 6806-2RS 30x42x7 Bearings - For supporting the Cam

- (1) 25kg RC Servo

- (1 - optional) Aluminum Servo Horn - I used these cause I had some extras from a previous project, but you could probably use the plastic one that comes with the servo if you prefer. Just have to find the right fasteners.

- Silicone Tubing - I've been using this aquirium air line tubing for a number of these projects recently. It's cheap and has seemed to work fine for me, but it's not technically made for liquids...so consider yourself informed. If you happen to know any reason I shouldn't be trusting this tubing, please do feel free to let me know!

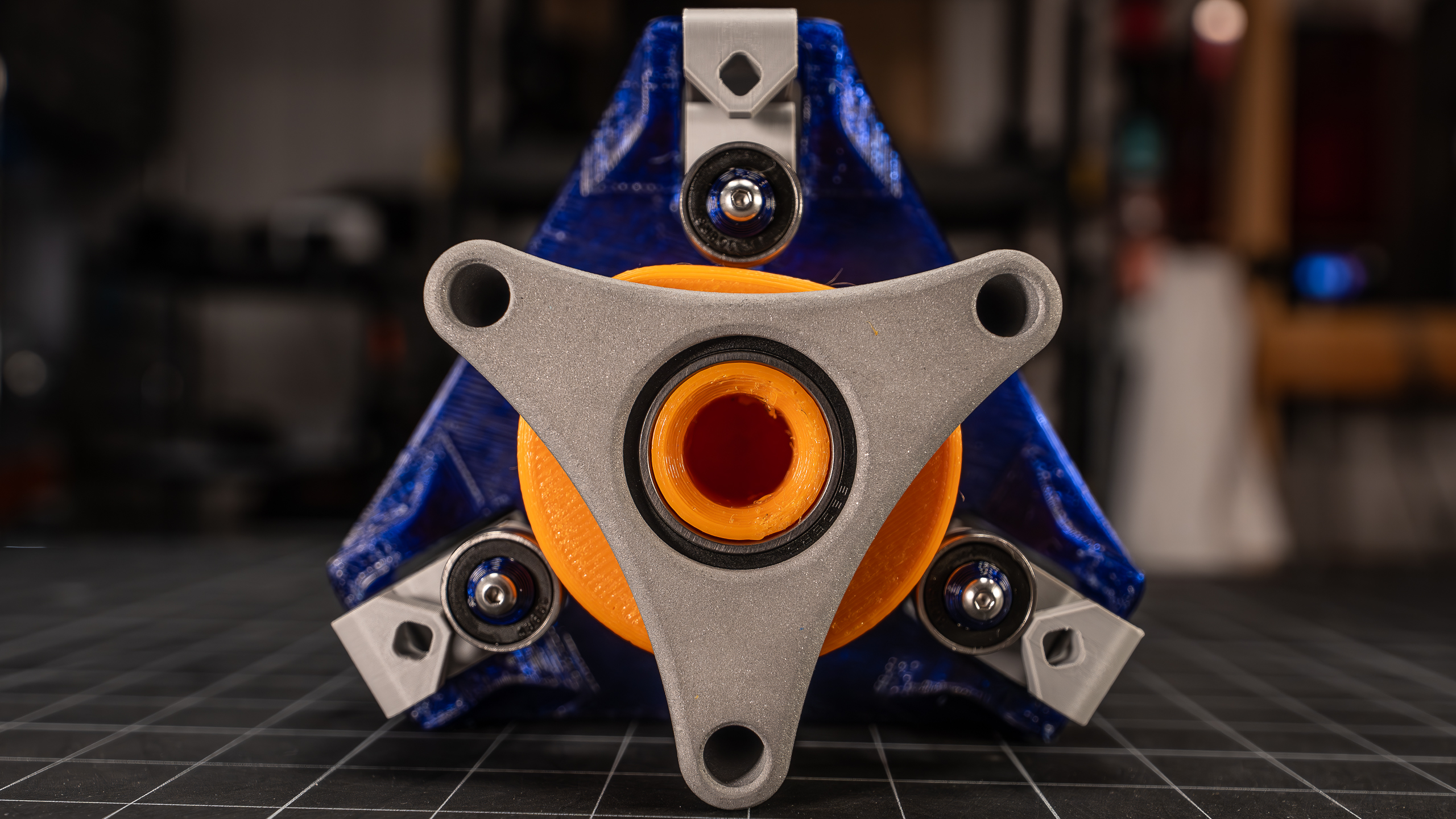

FRONT |

BACK |

|

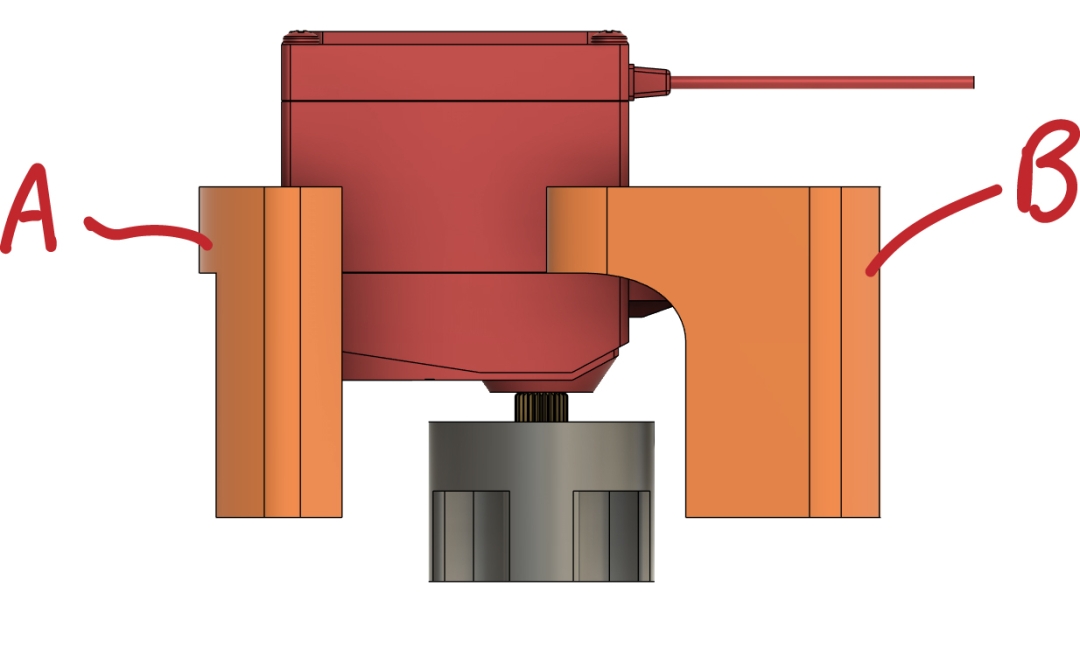

Mount A

|

Mount B

|

|

|

|

|

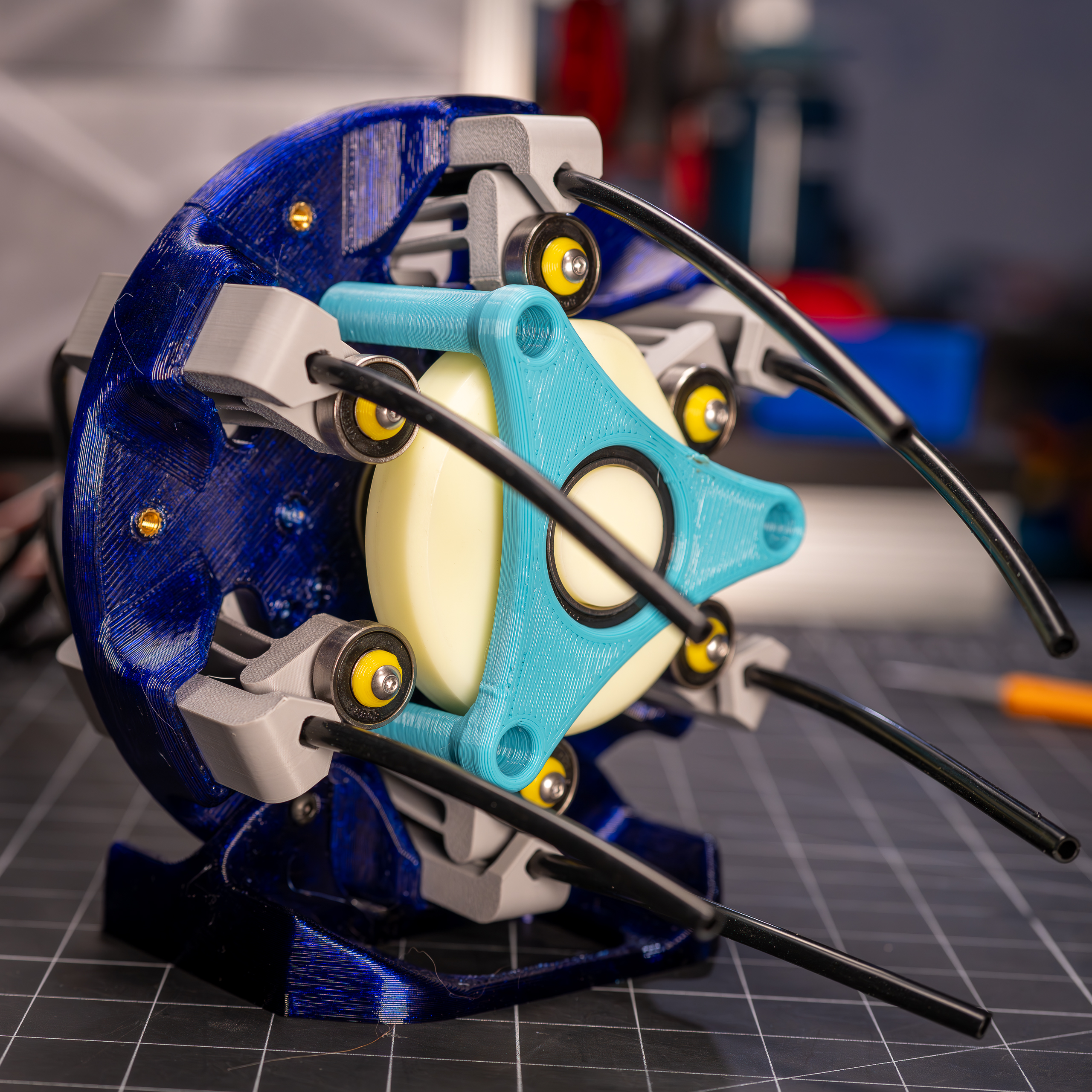

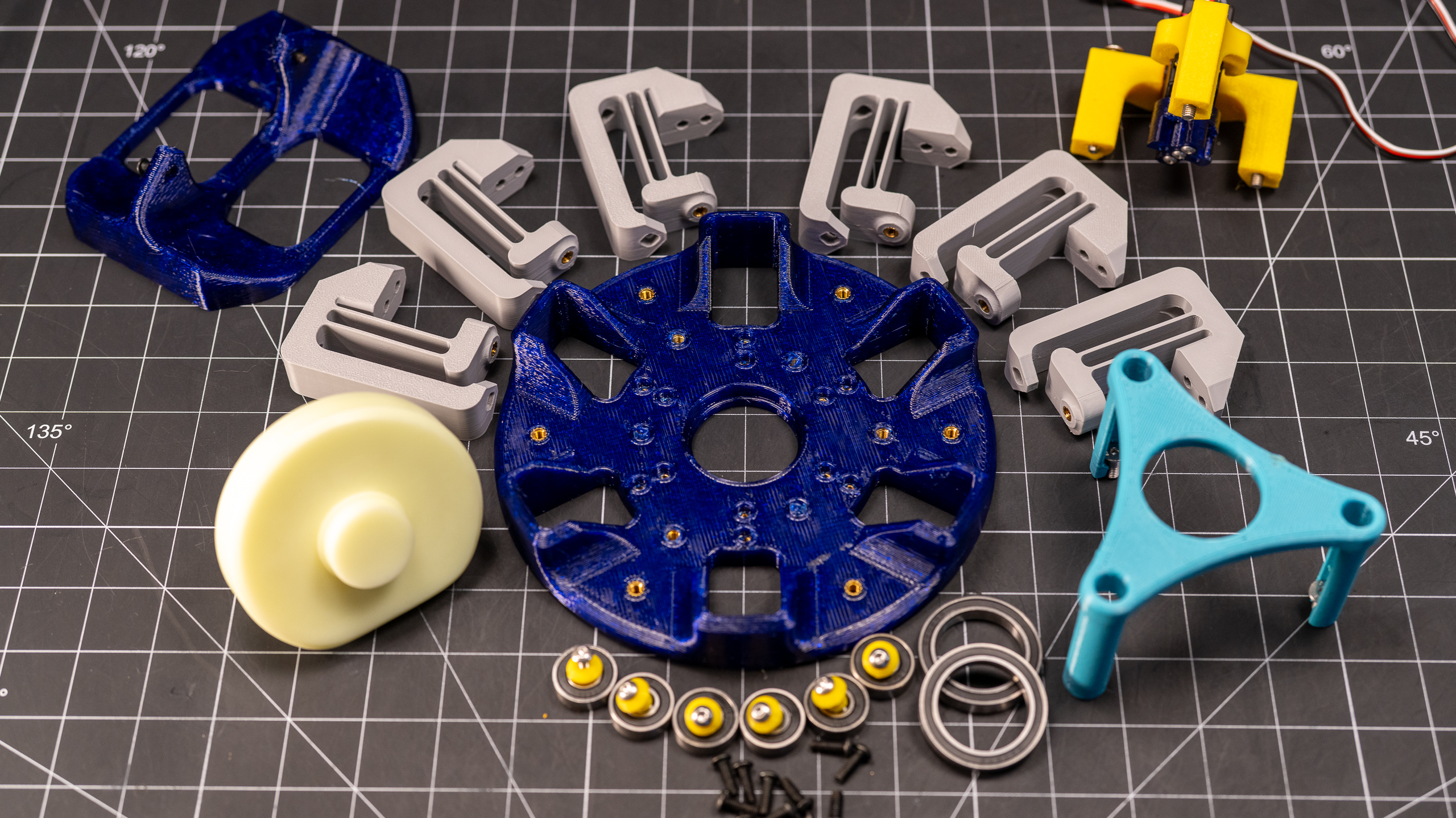

6 Channel

|

|

BOM

-

- Printed Parts

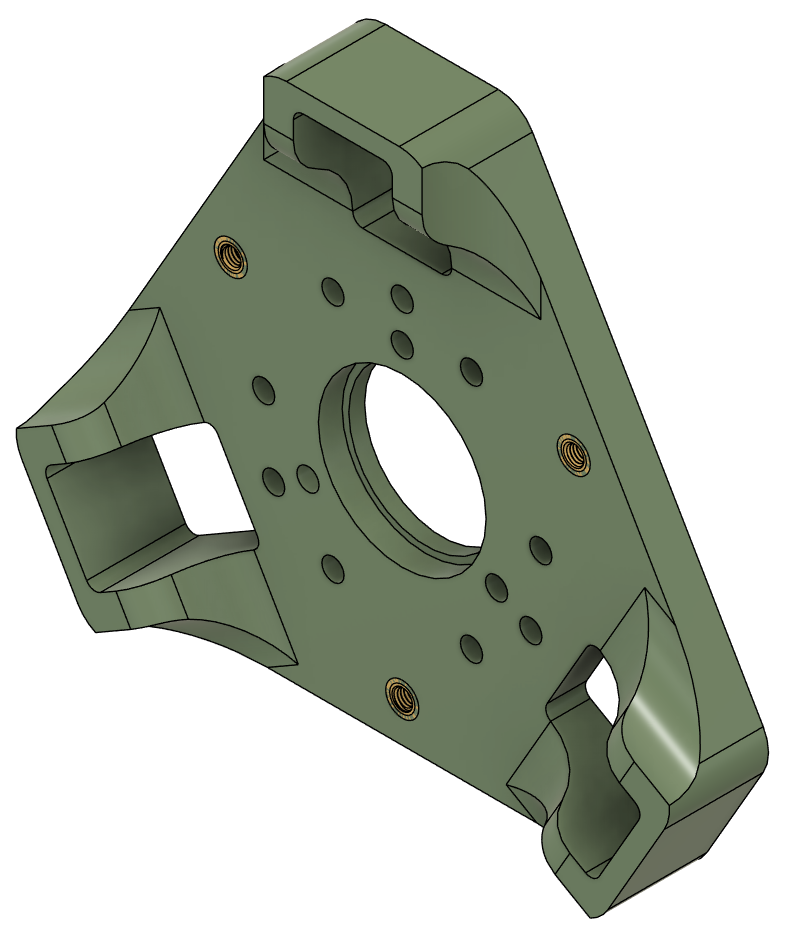

- (1) MainBody_6ch (aka "Base")

- (1) CamRetainer_6ch

- (1) Cam

- (1) Servo Mount A_6ch

- (1) Servo Mount B_6ch

- (1) Motor Coupler

- (6) Valve Flexure

- (6) Bearing Retainer

- COTs

- (28) M4 Heat set inserts

- (6) M5 Heat set inserts

- (16) M4x12 BHCS fasteners - Twelve for attaching flexures to Base and four for attaching servo to Servo Mounts. The latter can be shortened to as short as 8mm.

- (6) M4x16 BHCS fasteners - For attaching roller bearings to flexures

- (3) M5x45 BHCS fasteners - For attaching Servo Mounts to Base

- (3) M5x10 Flathead fasteners - For attaching Cam Retainer to Base. They don't need to be flatheads, that's just what I had, so what I used.

- (3-5) M3x20 BHCS fasteners - For attaching the Motor Coupler to the servo horn.

- (6) 608RS 8x22x7 Bearings - I bought this hundred pack since it makes the cost per bearing so damn lovely, but you obviously don't need nearly this many. This size bearing is the same as move roller skate bearings...FYI

- (2) 6806-2RS 30x42x7 Bearings - For supporting the Cam

- (1) 25kg RC Servo

- (1 - optional) Aluminum Servo Horn - I used these cause I had some extras from a previous project, but you could probably use the plastic one that comes with the servo if you prefer. Just have to find the right fasteners.

- Silicone Tubing - I've been using this aquirium air line tubing for a number of these projects recently. It's cheap and has seemed to work fine for me, but it's not technically made for liquids...so consider yourself informed. If you happen to know any reason I shouldn't be trusting this tubing, please do feel free to let me know!

- Printed Parts

|

FRONT

|

REAR

|

8 Channel

|

|

BOM

-

- Printed Parts

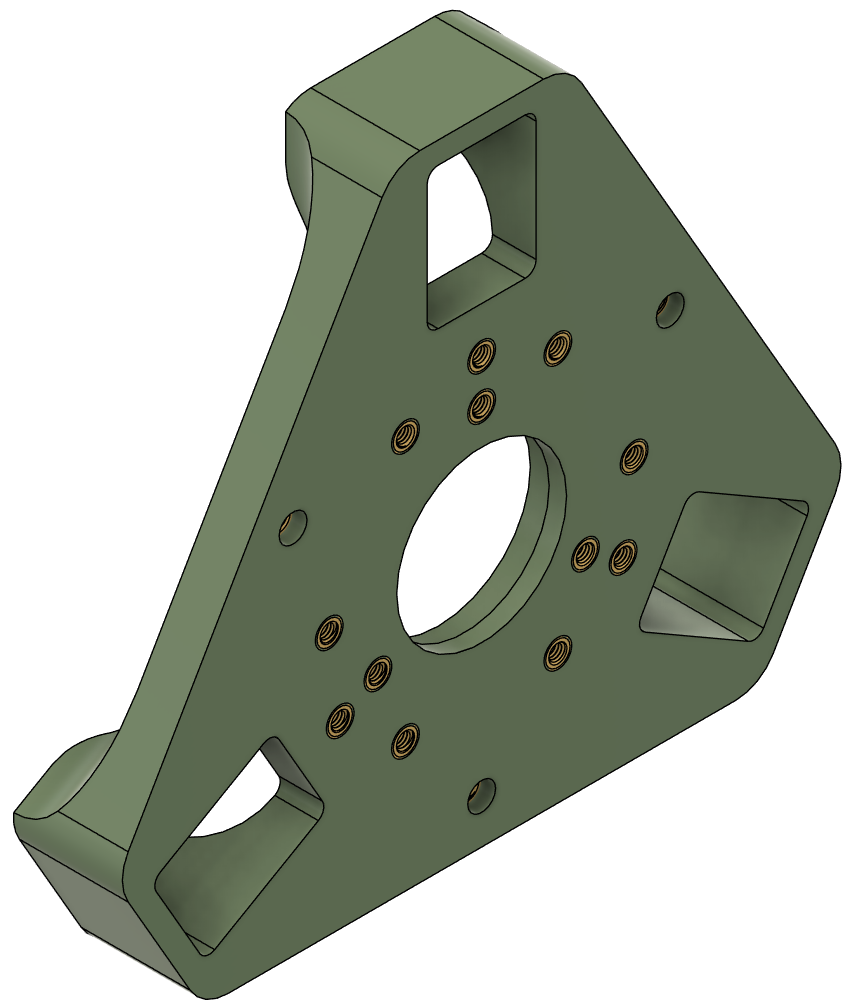

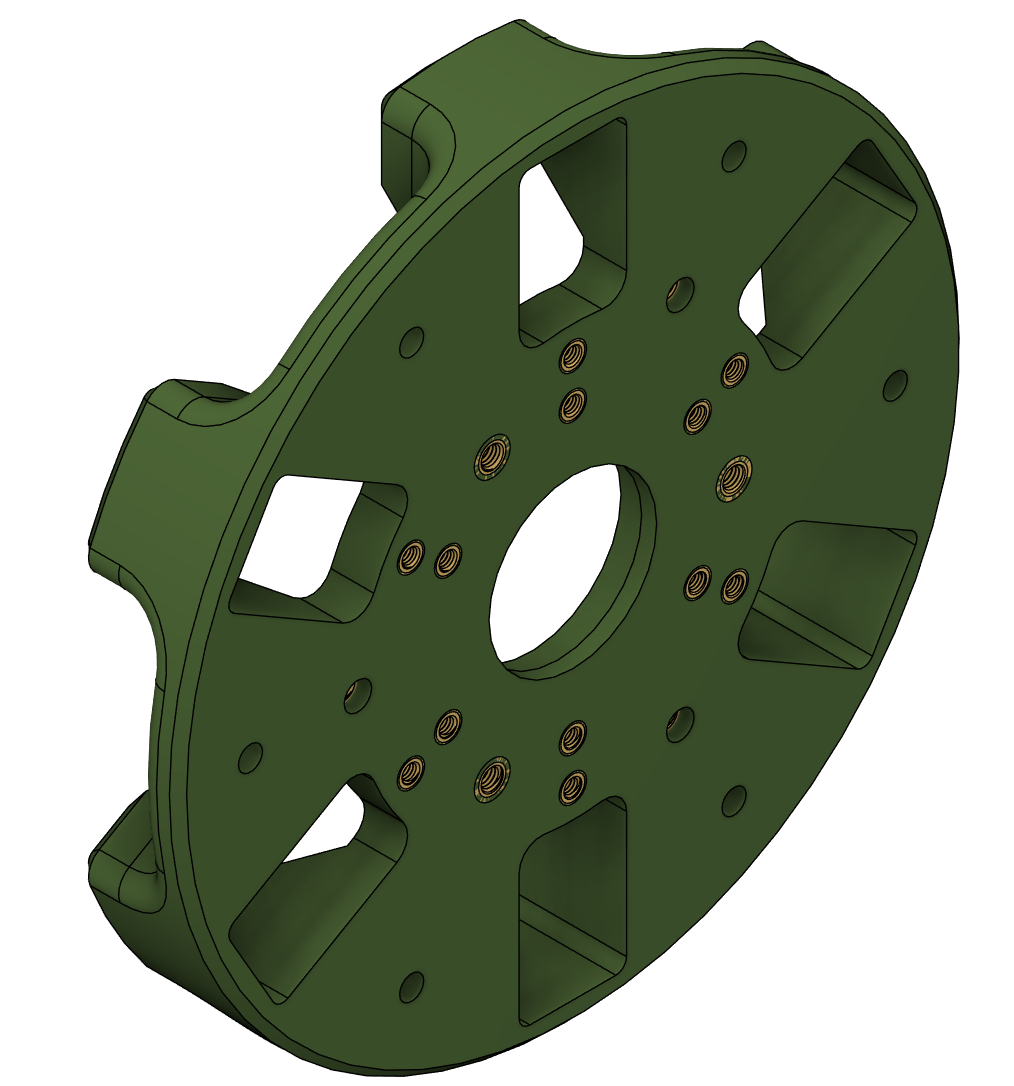

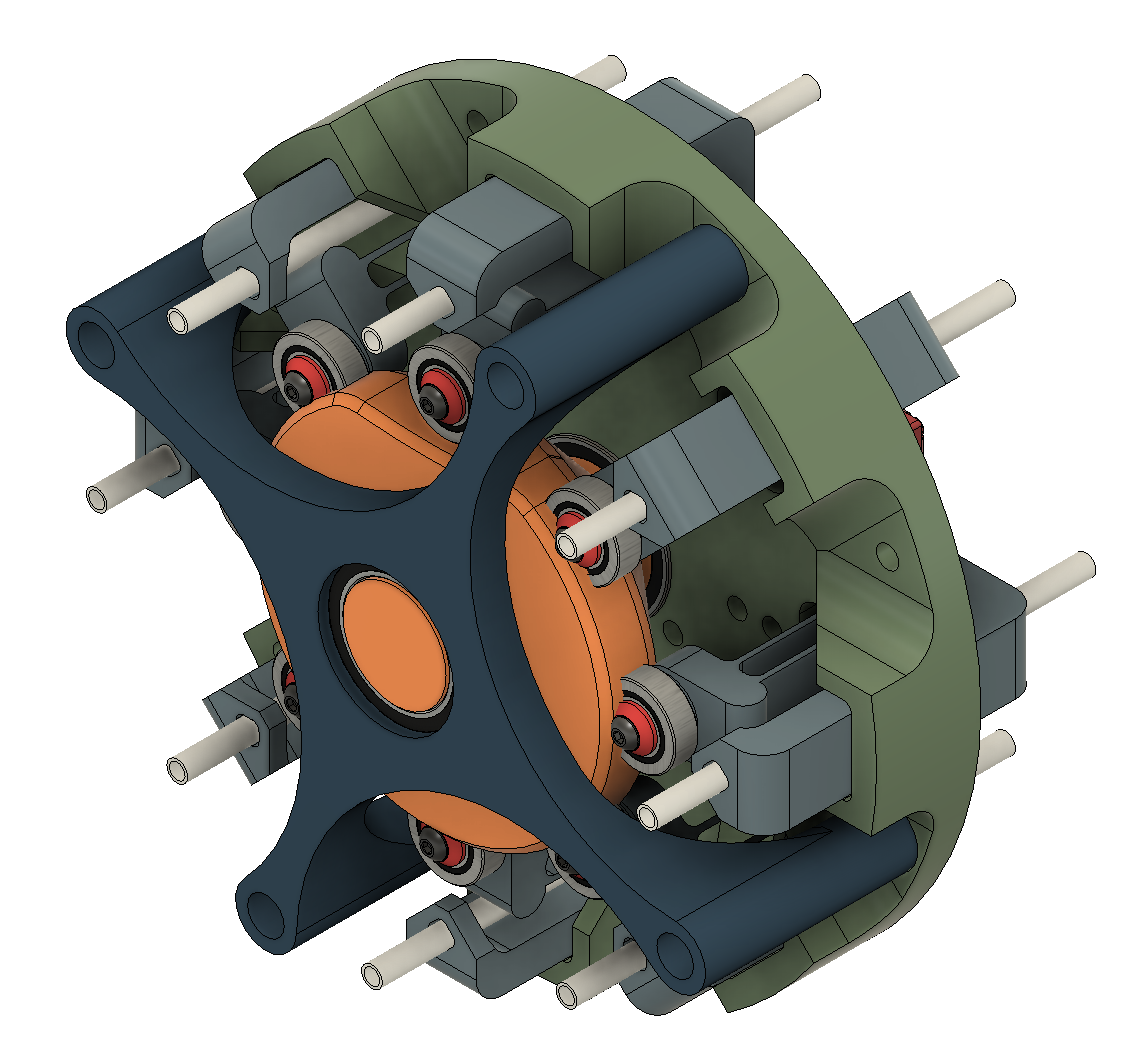

- (1) MainBody_8ch (aka "Base")

- (1) CamRetainer_8ch

- (1) Cam

- (1) Servo Mount A_8ch

- (1) Servo Mount B_8ch

- (1) Motor Coupler

- (8) Valve Flexure

- (8) Bearing Retainer

- COTs

- (32) M4 Heat set inserts

- (8) M5 Heat set inserts

- (20) M4x12 BHCS fasteners - Sixteen for attaching flexures to Base and four for attaching servo to Servo Mounts. The latter can be shortened to as short as 8mm.

- (8) M4x16 BHCS fasteners - For attaching roller bearings to flexures

- (4) M4x40 BHCS fasteners - For attaching Servo Mounts to Base

- (3) M5x10 Flathead fasteners - For attaching Cam Retainer to Base. They don't need to be flatheads, that's just what I had, so what I used.

- (3-5) M3x20 BHCS fasteners - For attaching the Motor Coupler to the servo horn.

- (8) 608RS 8x22x7 Bearings - I bought this hundred pack since it makes the cost per bearing so damn lovely, but you obviously don't need nearly this many. This size bearing is the same as move roller skate bearings...FYI

- (2) 6806-2RS 30x42x7 Bearings - For supporting the Cam

- (1) 45kg RC Servo - I originally assembled this with the same 25kg servo used on the others, but it struggled to rotated the cam consistently. So I swapped it with this 45kg one I had on hand that has the same outer dimensions. It's probably overkill, but it gets the job done.

- (1 - optional) Aluminum Servo Horn - I used these cause I had some extras from a previous project, but you could probably use the plastic one that comes with the servo if you prefer. Just have to find the right fasteners.

- Silicone Tubing - I've been using this aquirium air line tubing for a number of these projects recently. It's cheap and has seemed to work fine for me, but it's not technically made for liquids...so consider yourself informed. If you happen to know any reason I shouldn't be trusting this tubing, please do feel free to let me know!

- Printed Parts

- Details

- Parent Category: Hydration and Hydroponics Projects

- Category: Valving

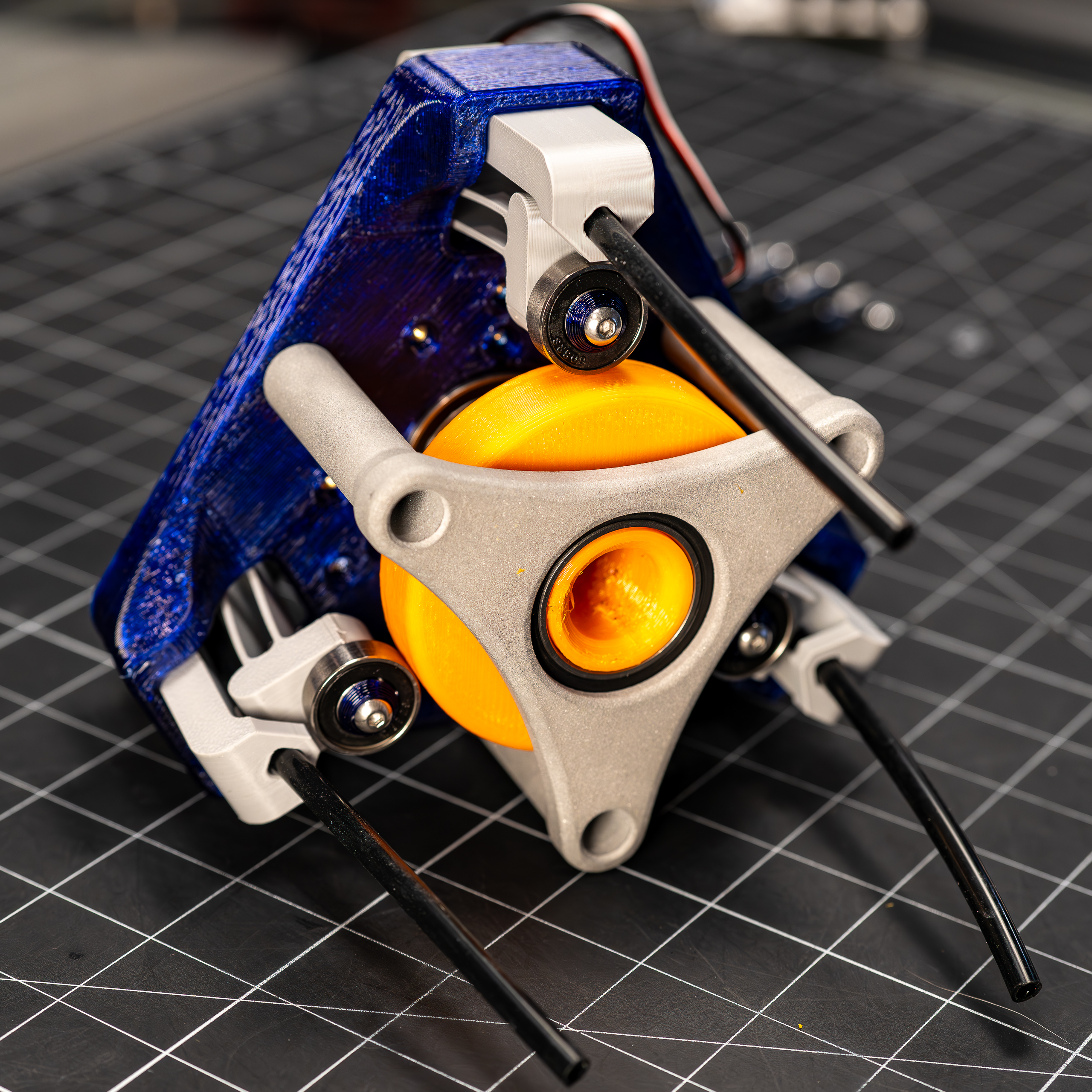

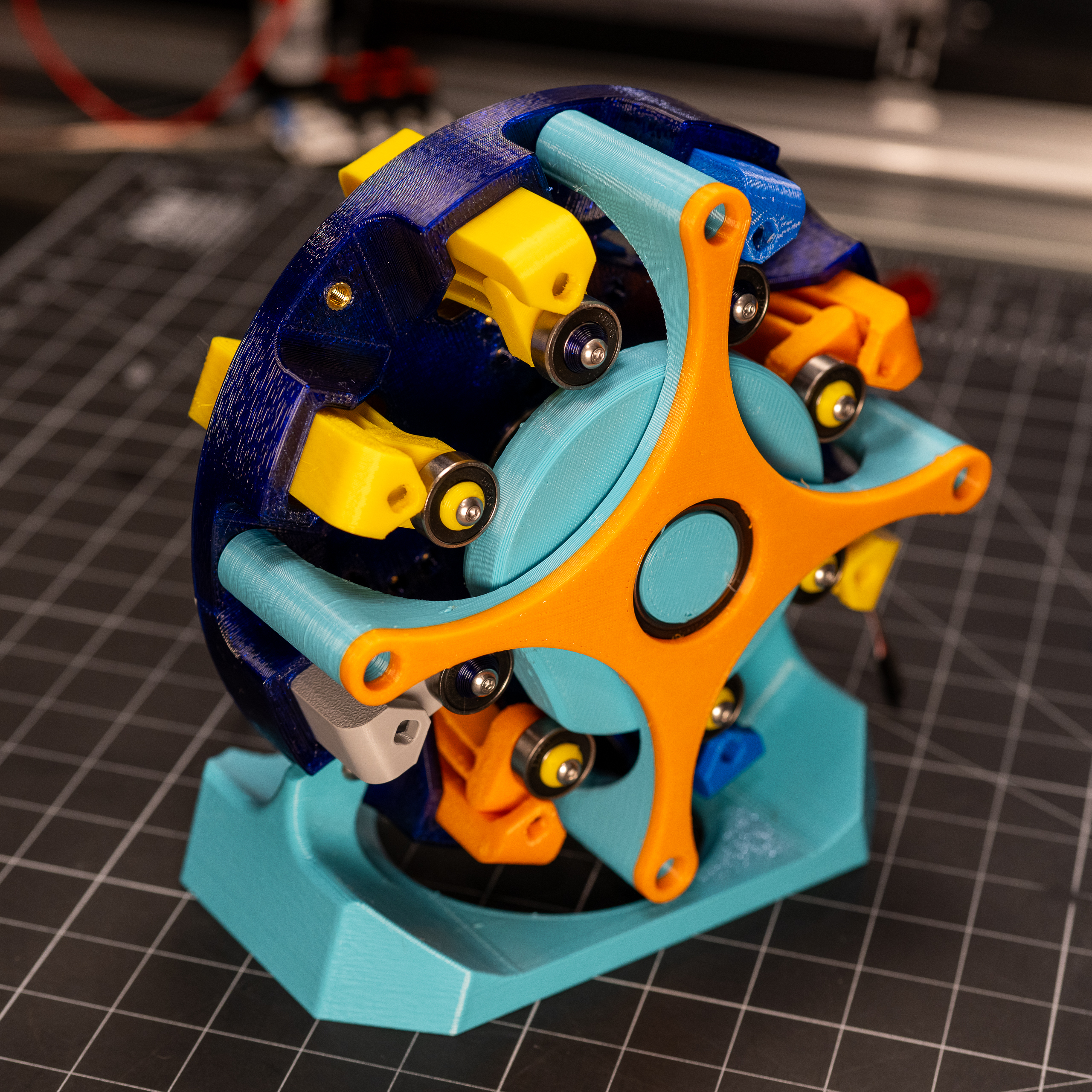

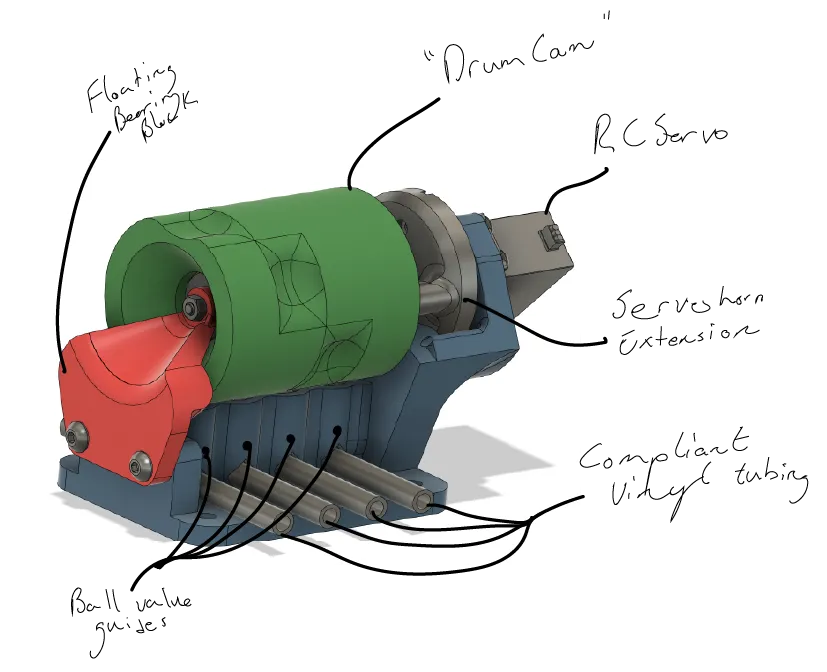

In my seemingly-endless tinkering with Peristaltic pumps, it occurred to me that the same concept used in a peristaltic pump to move fluid, could also be used to create a valve mechanism. So I decided to give it a shot, and it actually works pretty well!

Design

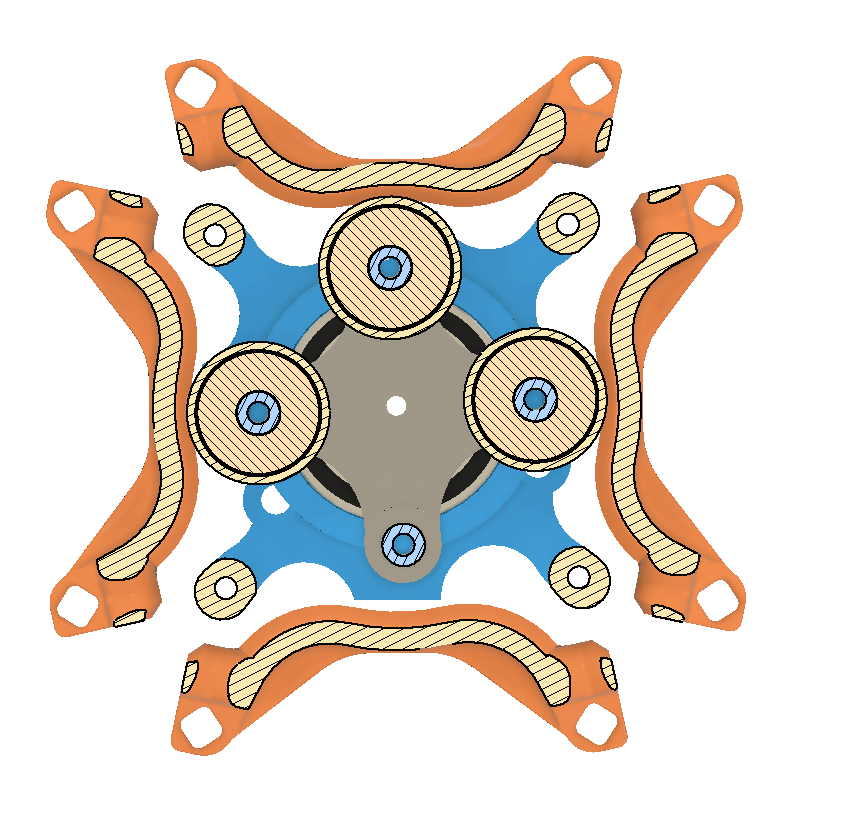

|

|

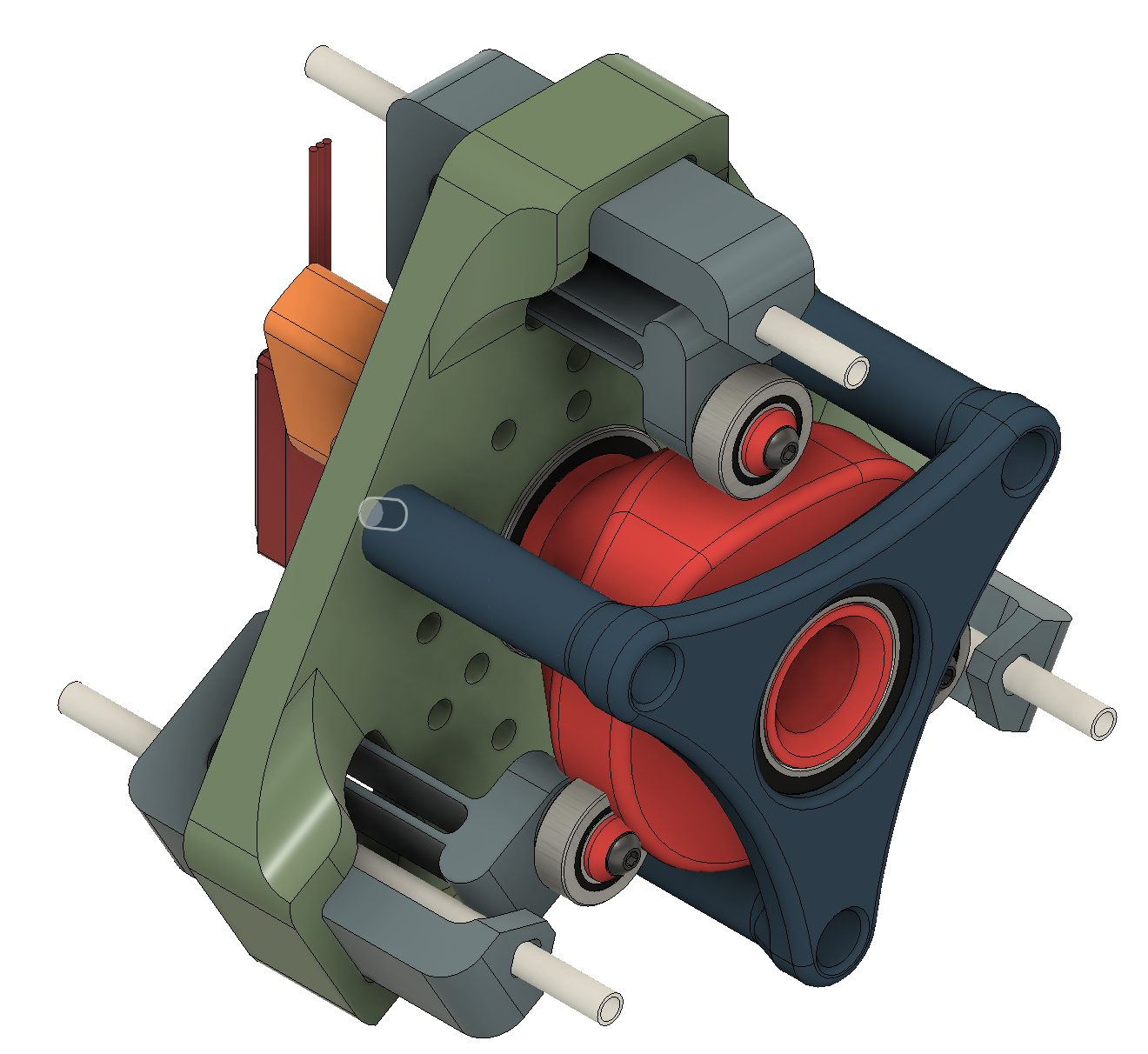

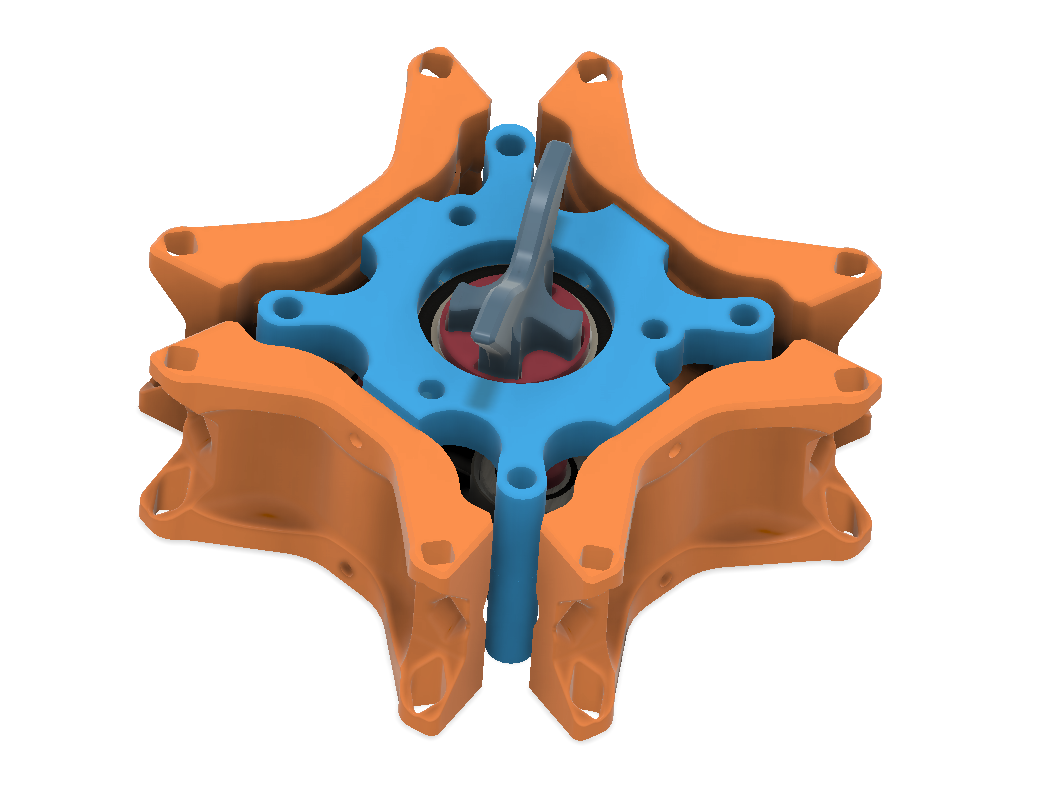

There are three main elements to the design:

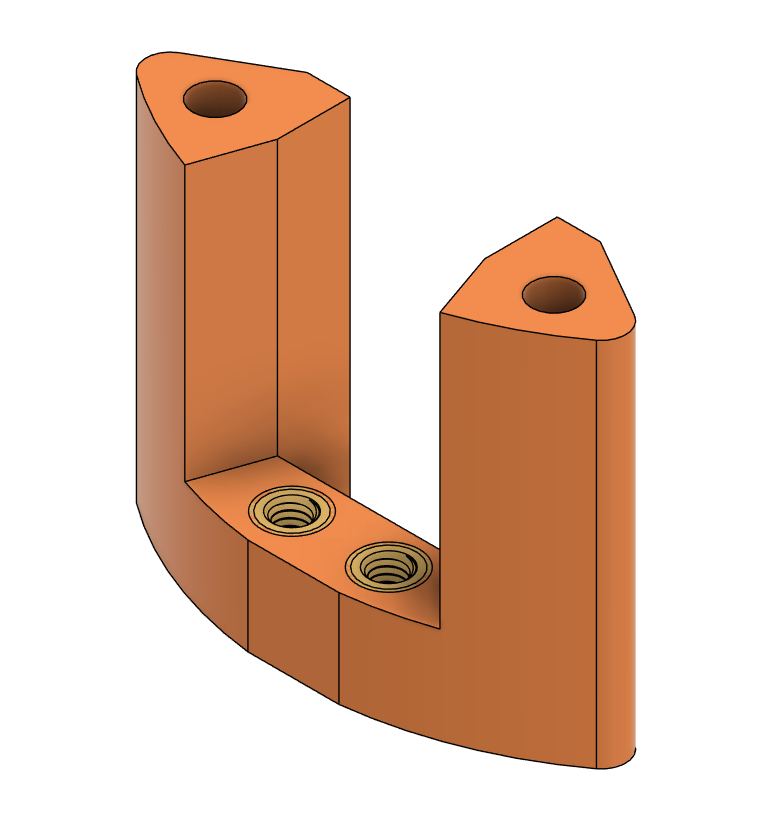

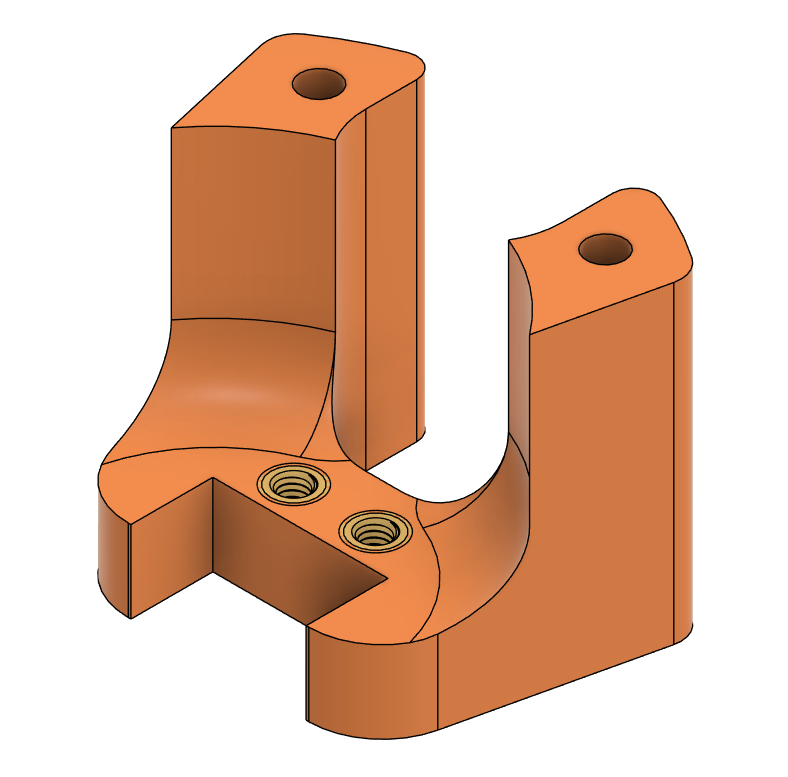

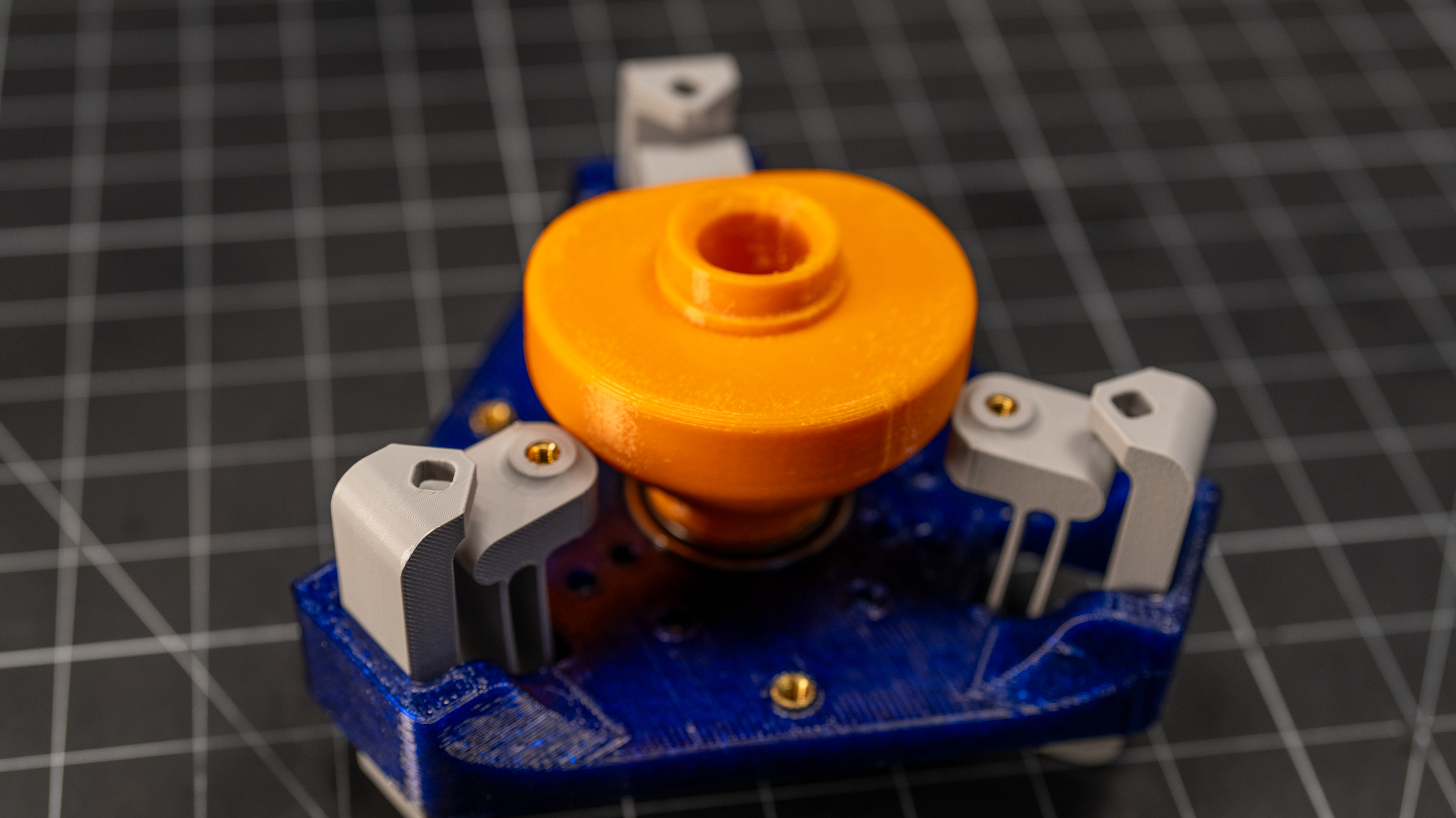

- The Shoes - These are shown in orange in the above images. These parts include the guides for the tubing, and the wall that the tube will be compressed against when closed. There is one shoe for each tube/channel that is being valved.

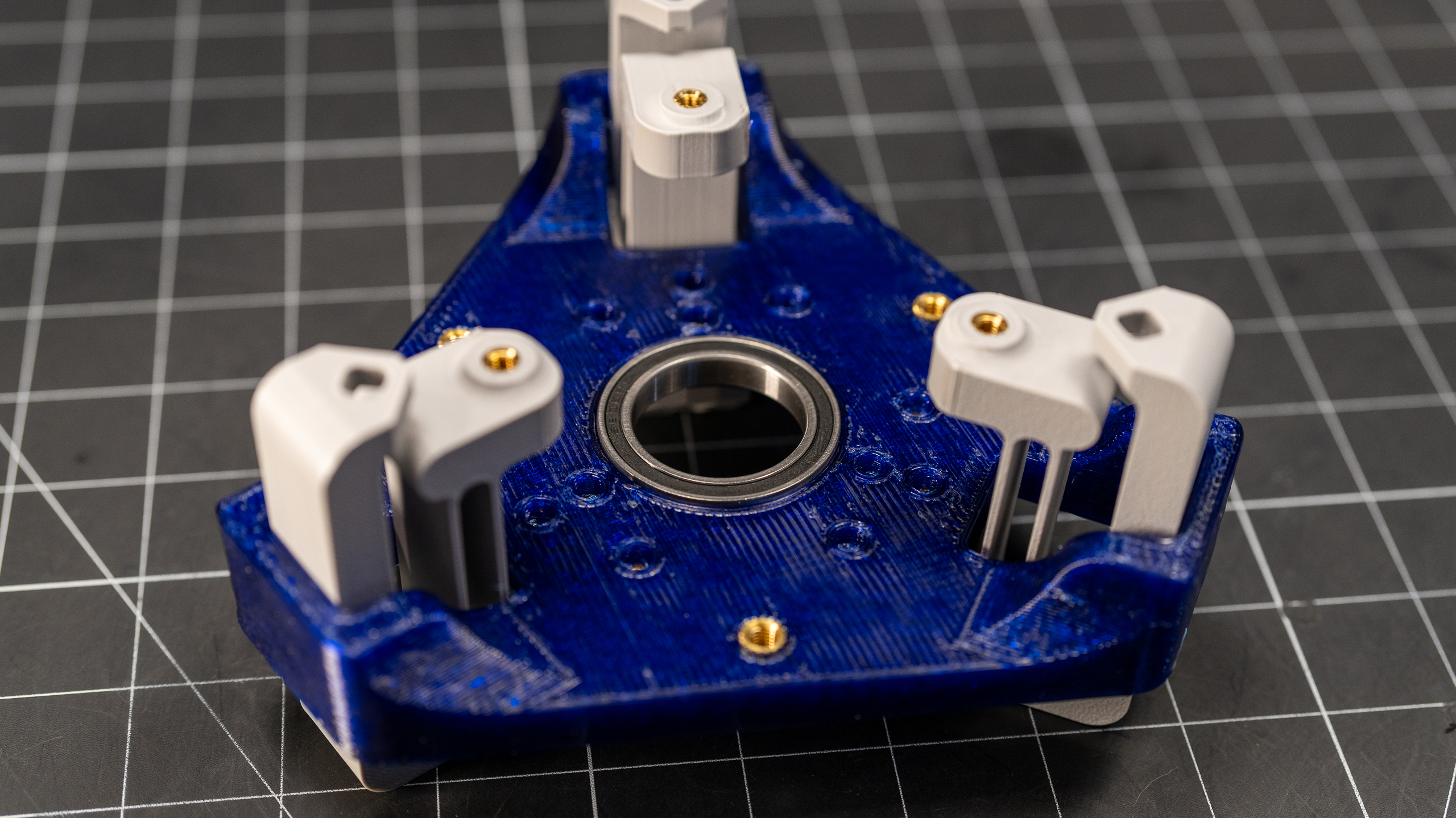

- The Stator(s) - Shown in electric blue in the images. These two parts bolt together, clamshell style, and act as the frame. They also house the main bearing journals that support the rotor.

- The Rotor(s) - Red and grey in the images. Both ends of the rotor have a motor coupler bearing journal. The rotors also have the attachment points for the bearings that will compress the tubing.

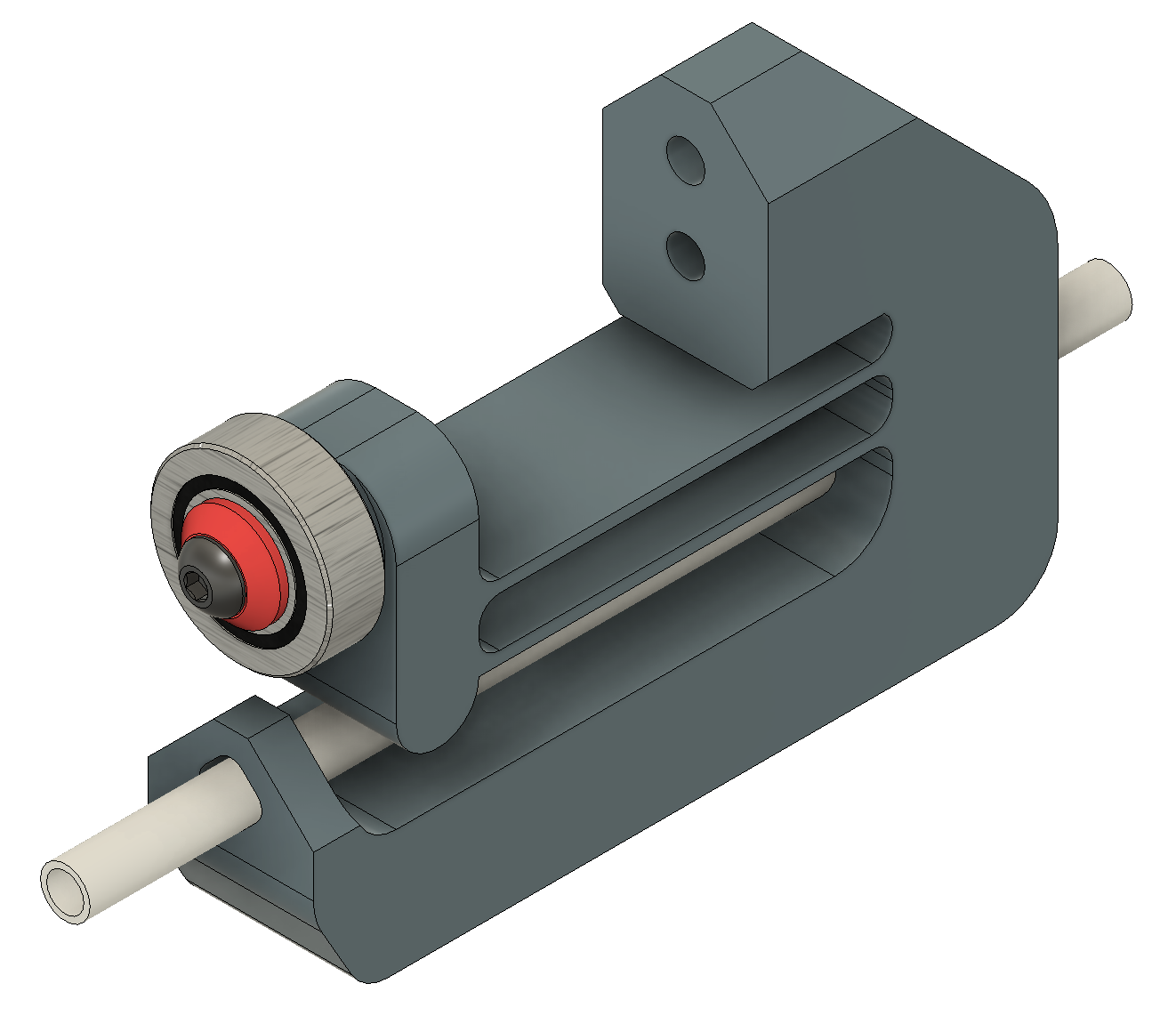

BOM

- Printed Parts

- (Qty 2) Frame.stl - These make the Stator

- (Qty 1) Rotor_Upper.stl

- (Qty 1) Rotor_Lower.stl

- (Qty 4) Shoe.stl

- (Qty 3) BearingCap.stl - These extend the contact patch for the bearing to cover the full tube and also can be easily swapped to vary the compression gap for different tubing and/or seal.

- (Qty 1) HandCrank.stl - To manually operate the valve - There are also mount locations on the Frame parts to attach a servo, but currently the drive torque required seems prohibitive (in my opinion)

- COTS

- (Qty 2) 6806-2RS Bearings / 30x42x7 - The 'main bearings'

- (Qty 3) 608-2RS Bearings / 8x22x7 - Aka roller skate bearings. These are the compressors (or so I will now call them)

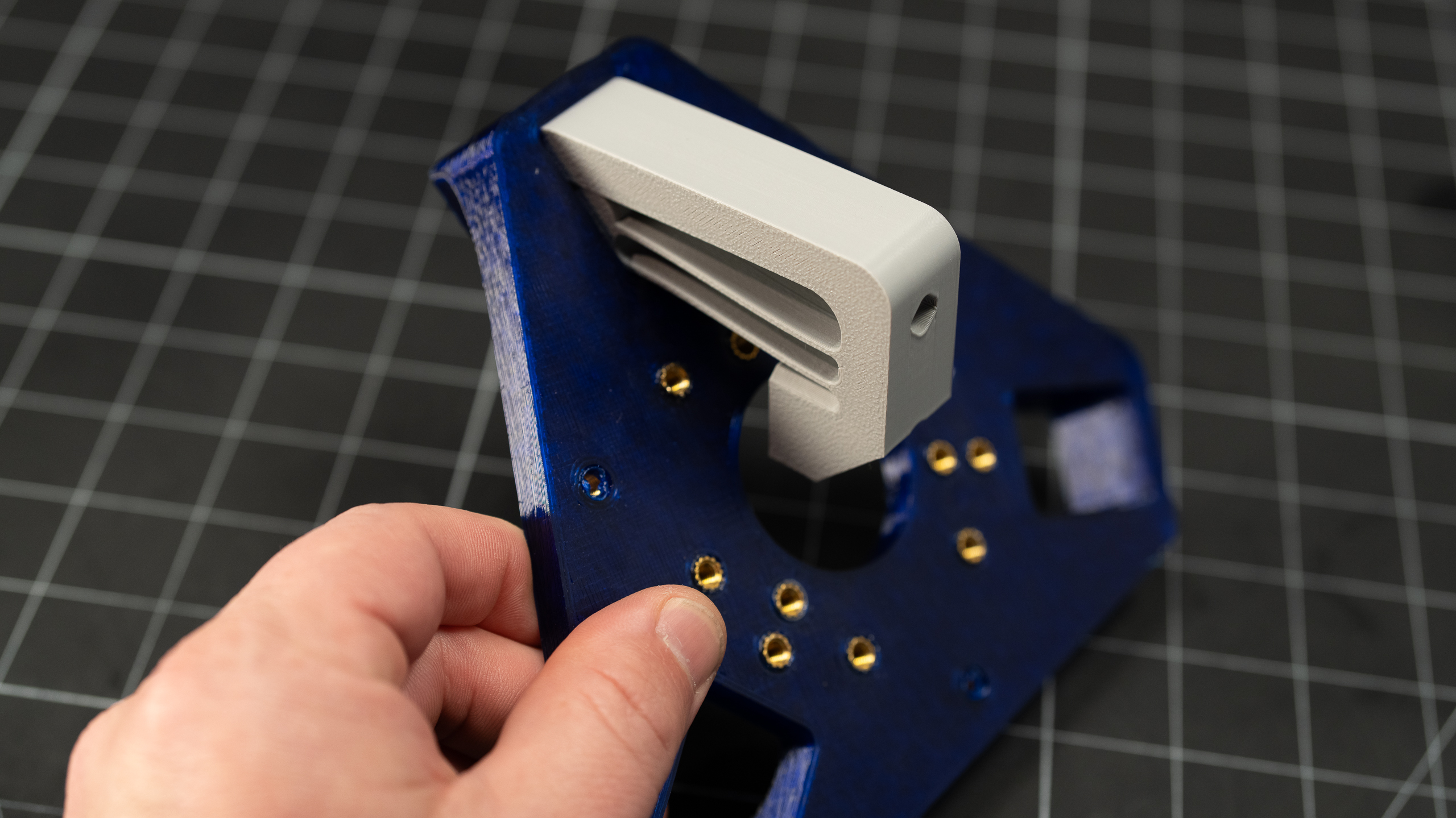

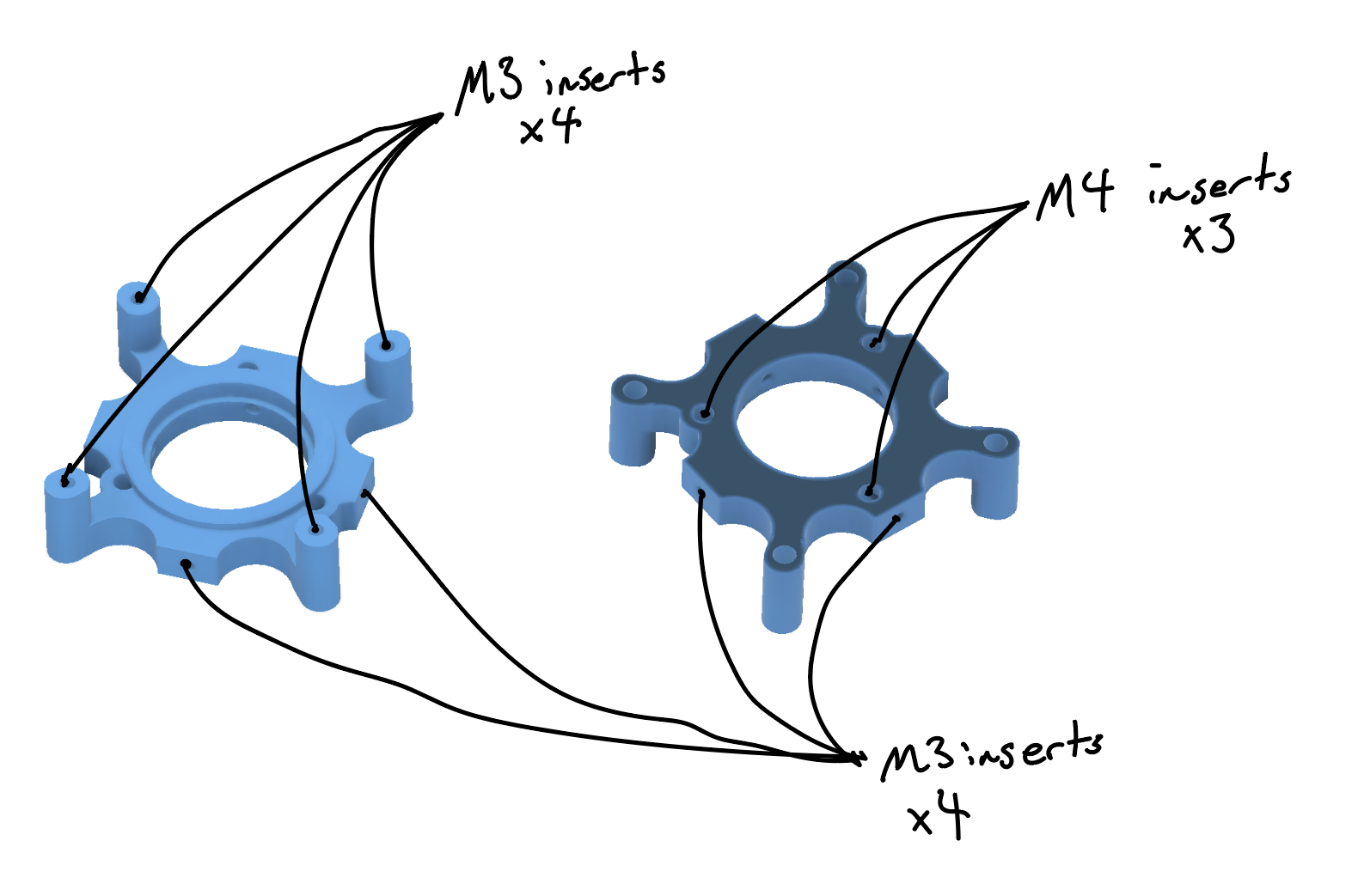

- (Qty 16) M3 Heat Set Inserts - Numerous spots, see below images.

- (Qty 6 - Optional) - M4 Heat set inserts - These are for the top and bottom mount locations intended for motor mounts.

Heat set locations

One of the frames will have four, M3 heat sets inserted for attaching the frames together. These should be inserted from the inside (the smaller diameter).

Both frames will get four, M3 heat sets inserted around the perimeter, for attaching the shoes.

If you are going to insert the M4s into the frames, be careful when inserting the M3s to not obstruct the one M4 hole that intersects. You may want to use a shorter M3 for these holes.

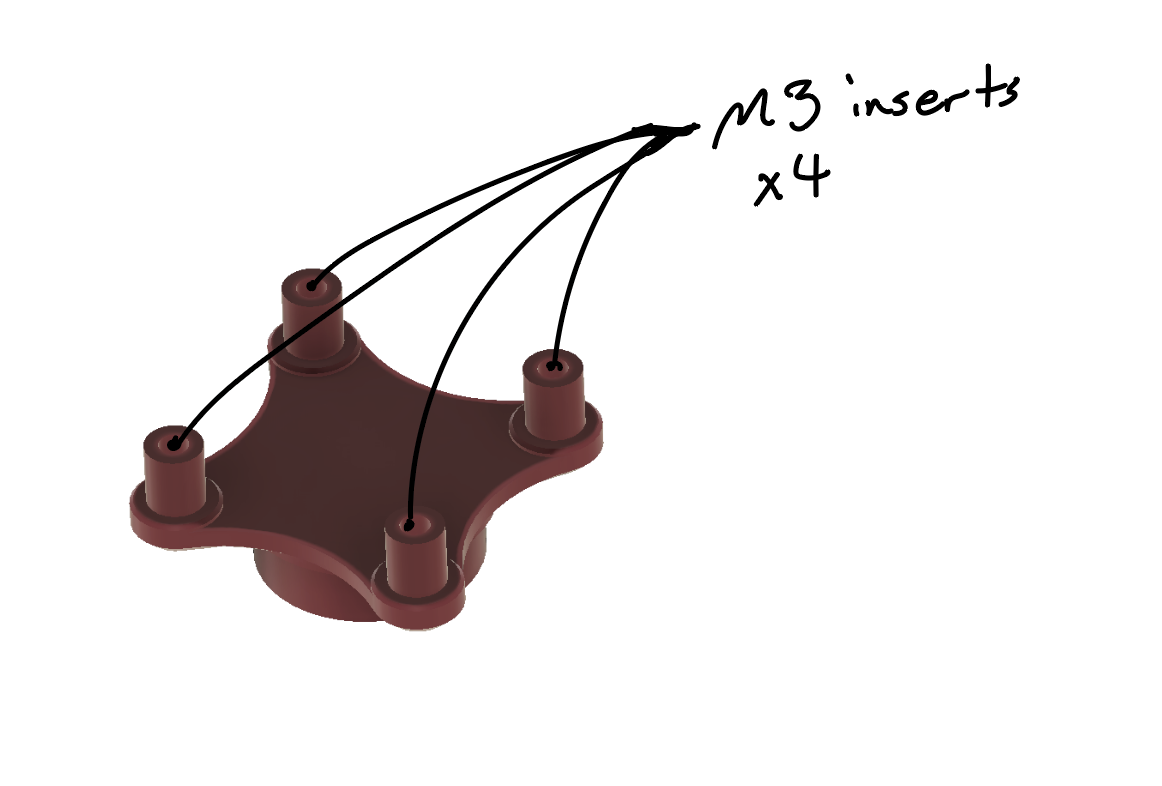

The final M3s go into the Rotor_Upper. I was wanting to test using the expansion of the post when inserting the heat set to make an interference fit with the bearing, but I was too conservative on my post diameter. So no need to have the bearings in place when inserting the heat sets.

|

|

- Details

- Parent Category: Hydration and Hydroponics Projects

- Category: Valving

This design is for a digitally-controlled, four ‘channel’ valve assembly. I designed this specifically for the application shown in the picture above, where I wanted to be able to controllably dose from individual reservoirs to individual target plants. By combining a couple of these valves with a peristaltic pump, I could supply four plants from up to three reservoirs.

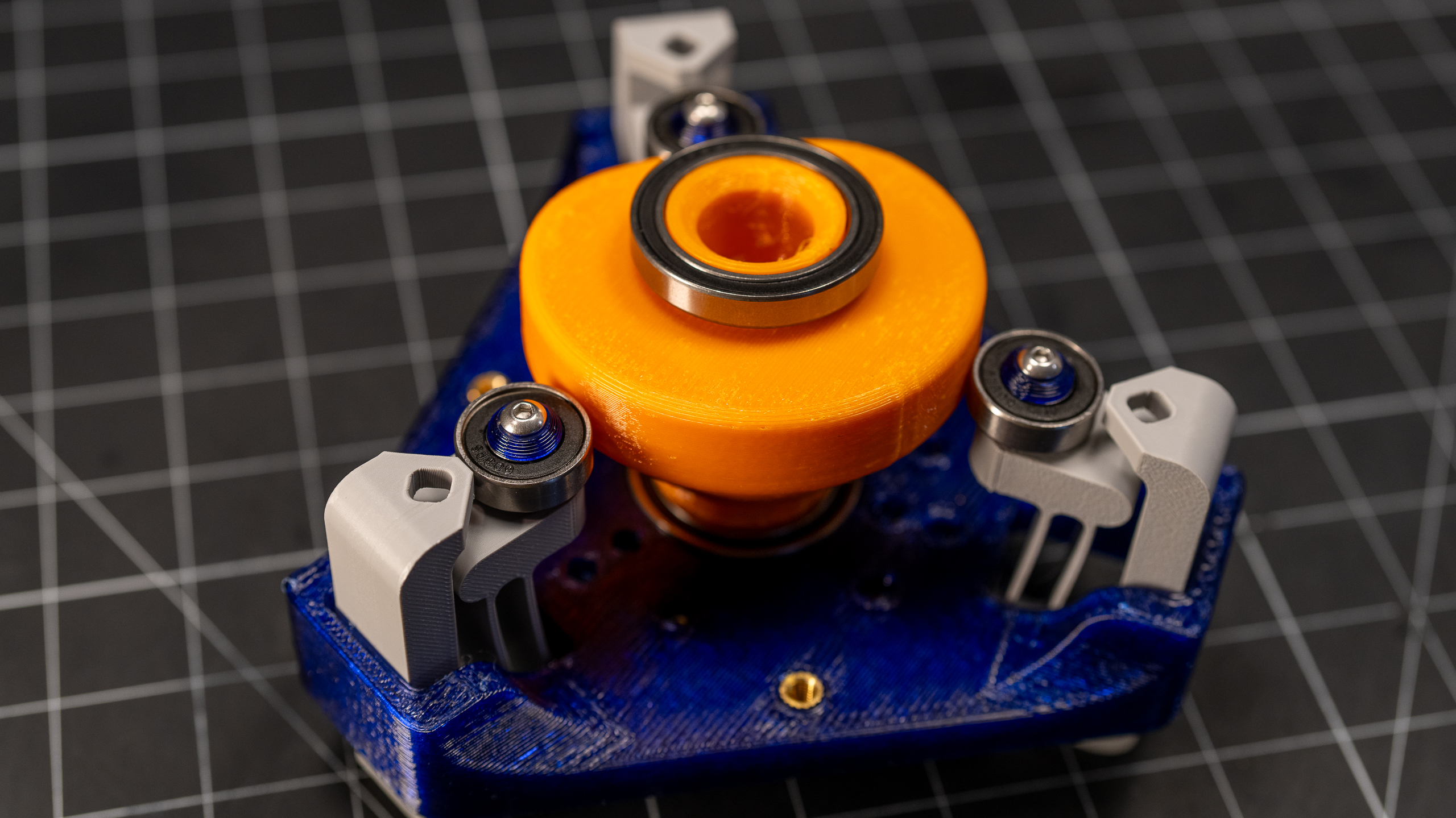

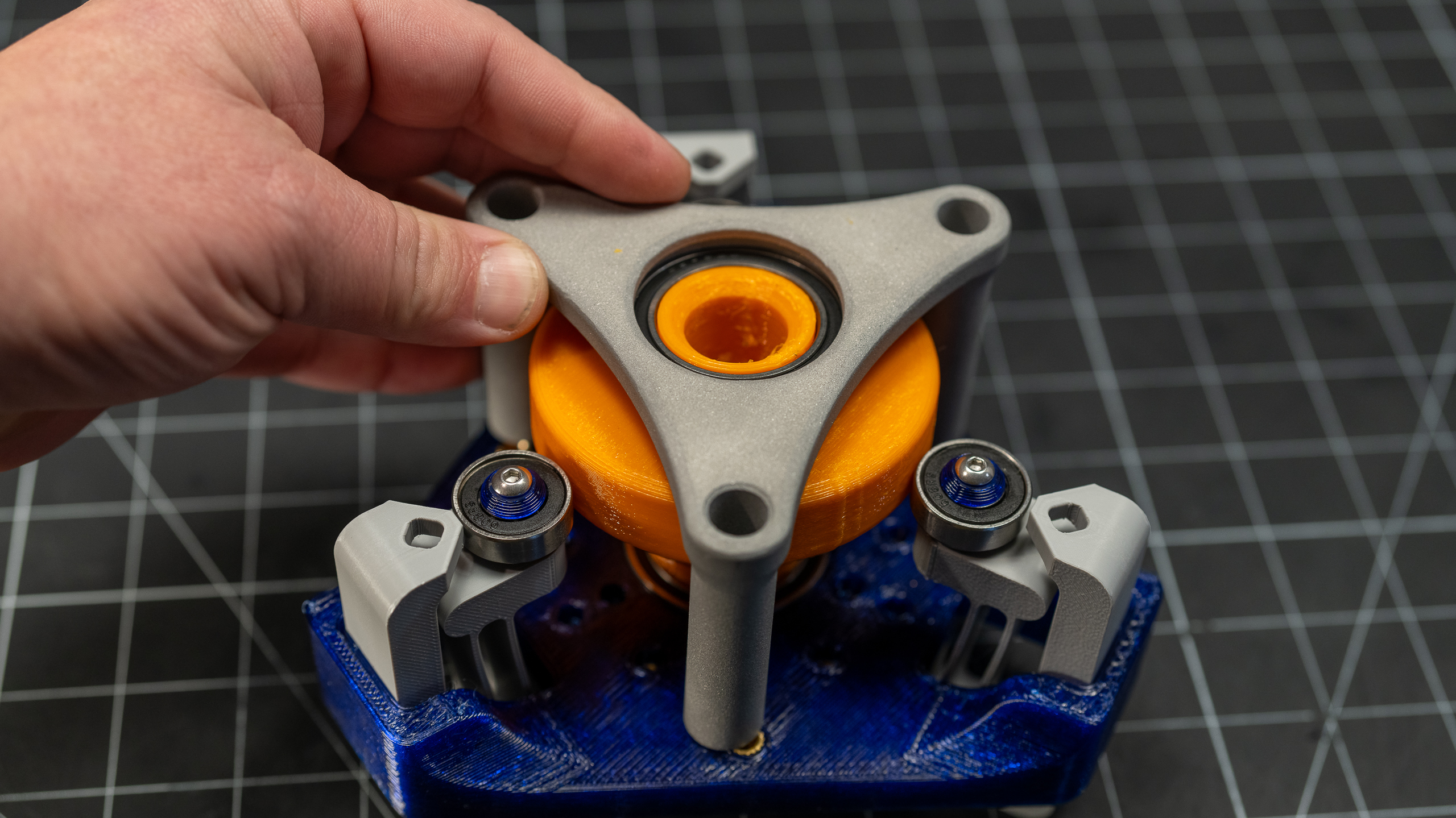

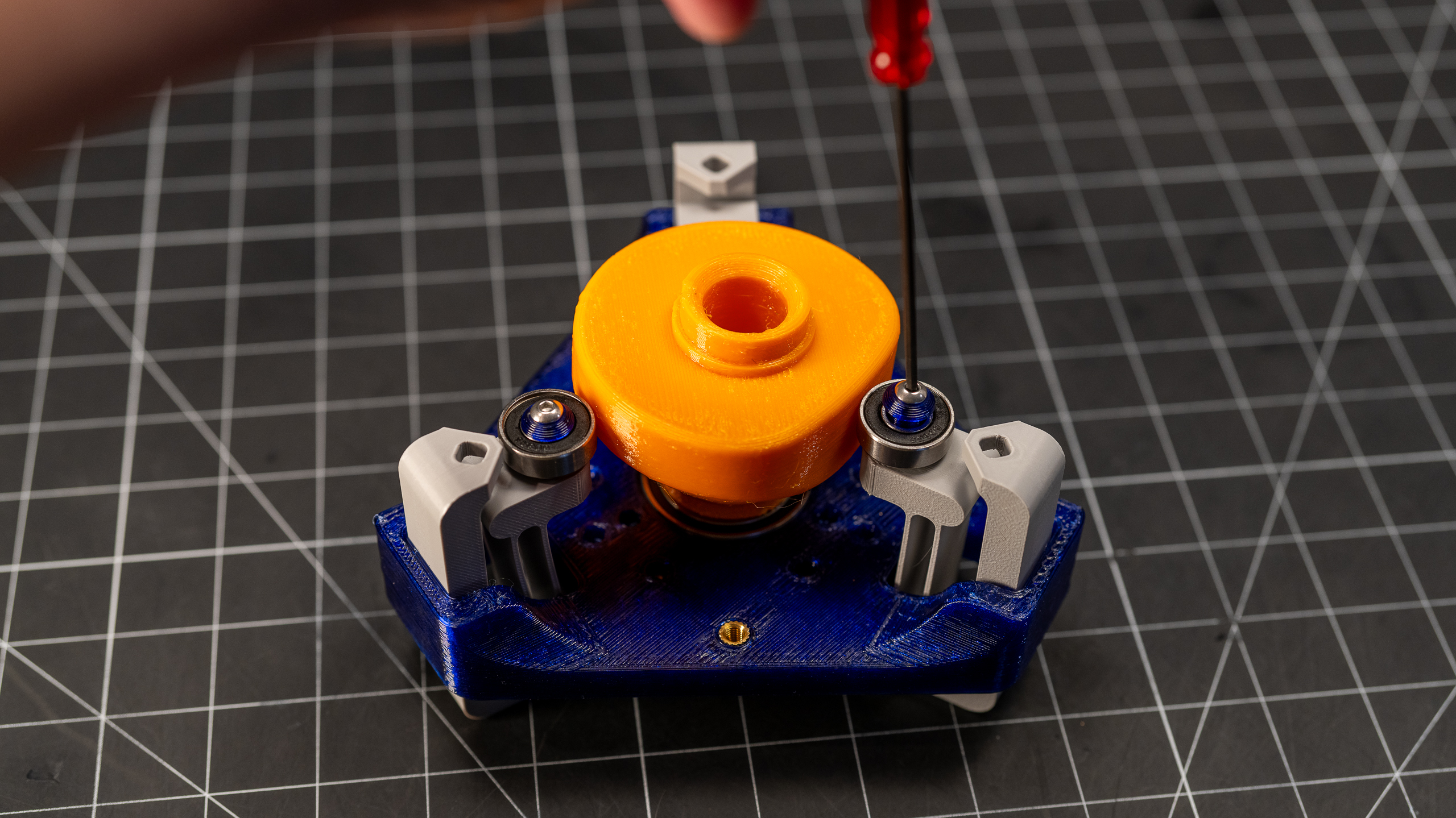

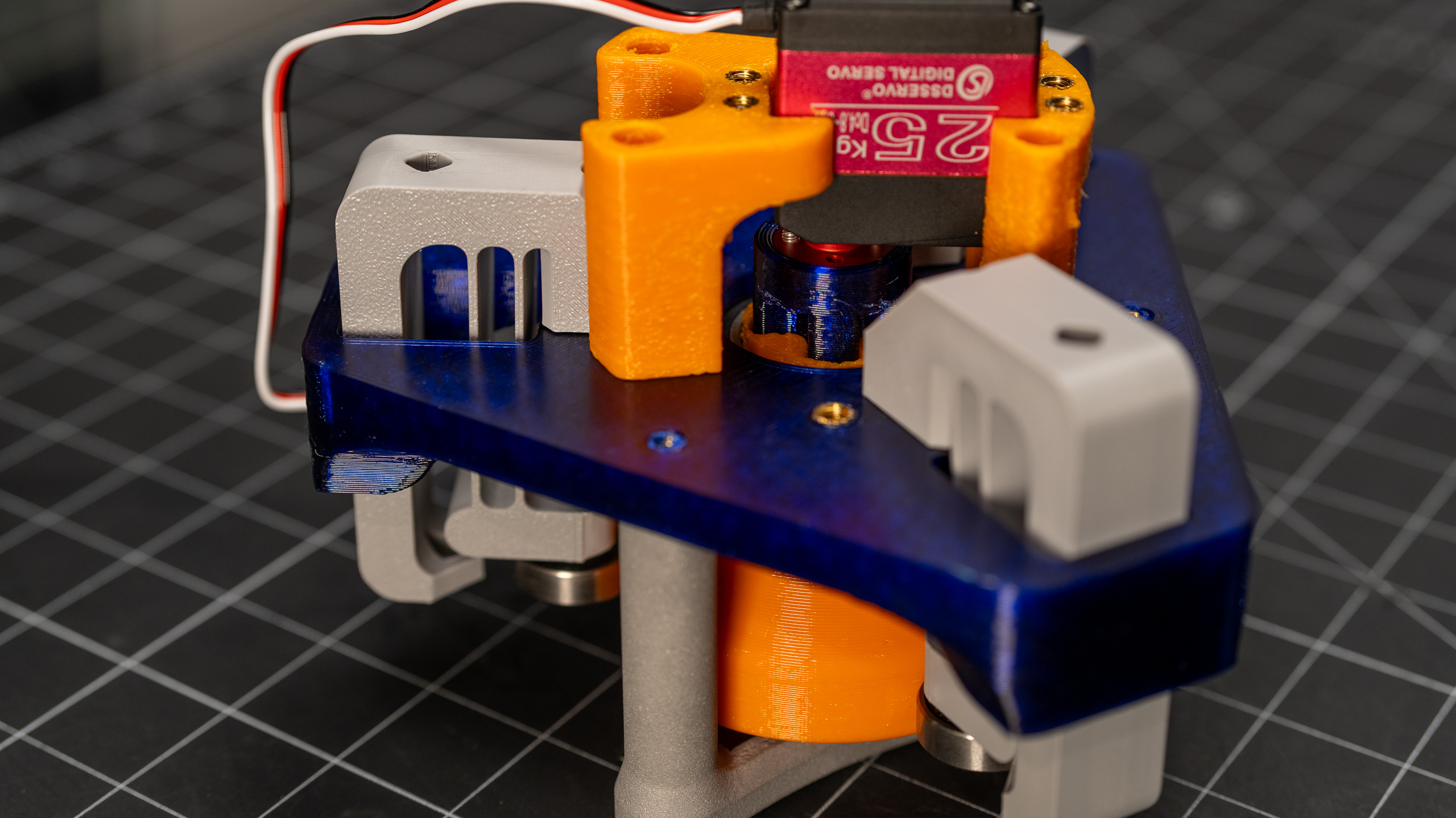

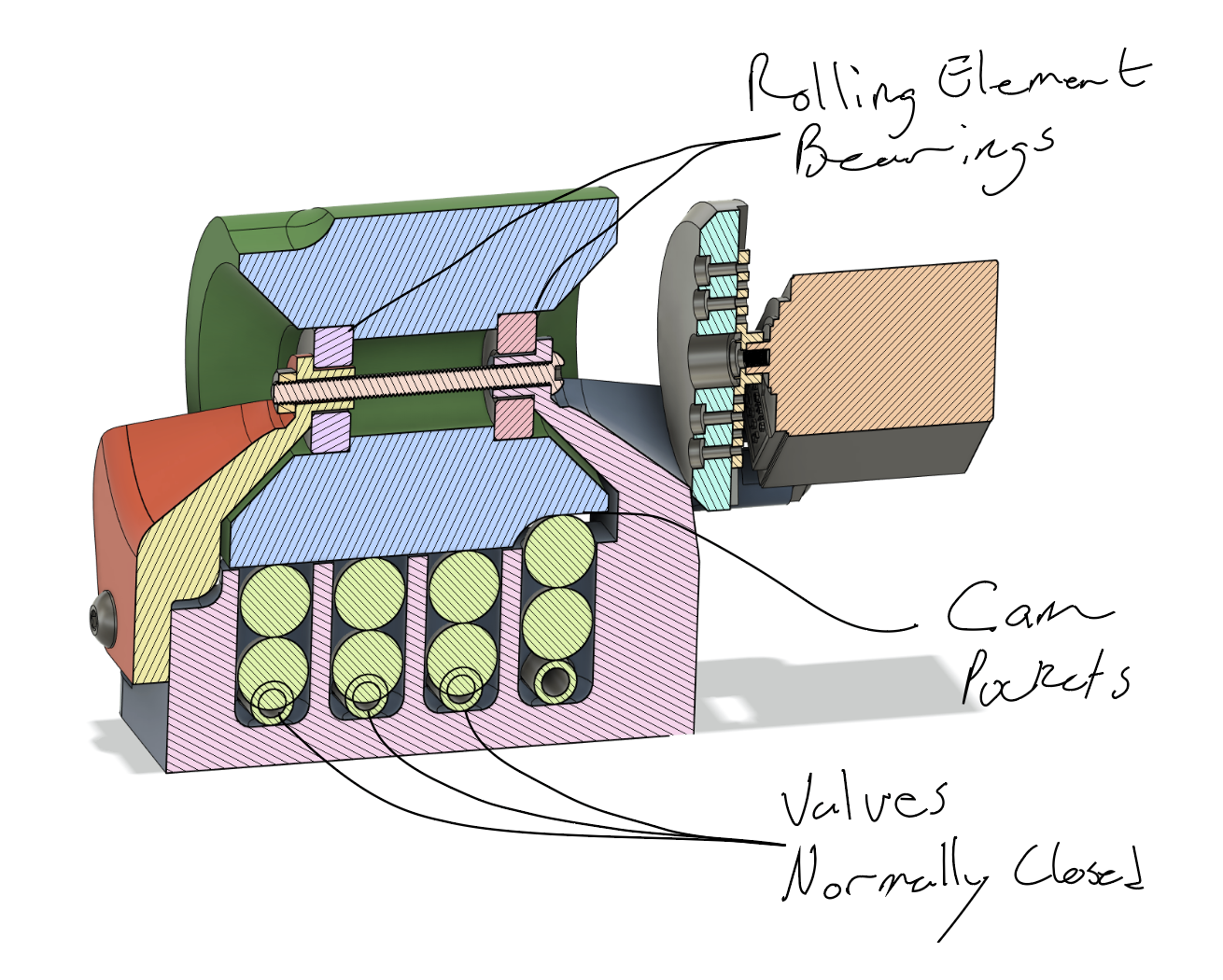

The valve works by the camshaft pushing steel balls against the tubing passing through the valve. The channels are closed except when the cam rotates such that the ‘pocket’ for that channel is rotated such that the ball can lift and release the tube. The video below shows one in action.

Design Overview

A good friend (and far better engineer than I) was kind enough to record a full Design Review video for this…but technical difficulties (aka I’m still new to OBS Studio) meant none of his audio was captured…oops…I am curious if people would actually be interested in these sorts of Design Review videos, any opinions or suggestions would be much appreciated!

Parts List

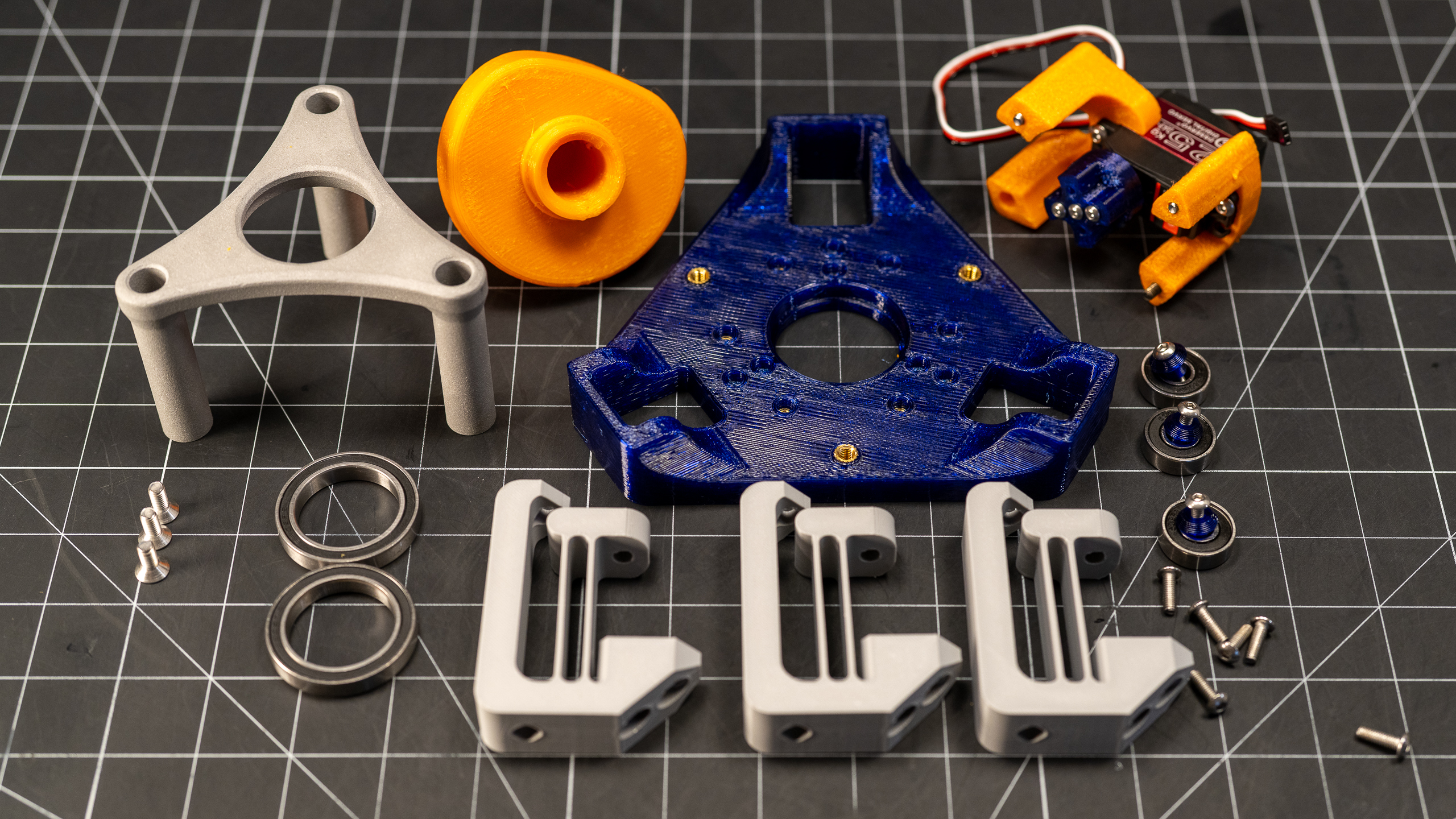

Printed Parts:

I’ve now made a handful of these valves, and I’ve made all of them from Overture PETG. I generally like working with PETG, and it holds up well for these. The only downside is that PETG does wear a bit at the contact between the drum and the steel balls. I haven’t experienced any problems, but I anticipate it will lead to progressively worse sealing over time. I didn’t want to use PLA because I expect mine to see a fair bit of UV exposure, but I’d be quite curious to hear what else folks try and what works well.

- DrumCam.stl

- Housing.stl

- CamSupport.stl

- ServoInterface.stl

Please note, I sliced/printed these prior to the release of organic supports in Prusa Slicer, of which I am a very big fan. If I were printing these today I would use organic supports…and actually, I just realized that for the build I did in the images below, I did indeed slice it with them. But the screenshot I saved, is the screenshot I saved!

COTS parts

- (Qty 2) 608 2RS Bearings — Aka skate board bearings. There’s not much demand on these bearings unless you’re putting yours in some weird/harsh environment, so any 8x22x7mm bearing should do fine.

- (Qty 1) DS3225 Servo — It was originally designed for, and still can be built with, an MG995 servo, but while it seemed to operate fine for several weeks, I felt like it sounded like it was loading closer to stall than I wanted.

- (Qty 8) 1/2" or 12.5mm balls — I have just been buying these in different sizes recently, but you obviously don’t need 100 pieces for this project.

- (Qty ?) 5mm x 8mm Silicone Tubing — You’re looking for a compliant/soft tubing with the matching ID/OD. You would probably be fine (and maybe even get slightly better sealing) with a thicker wall, but at the cost of more Cam wear.

- (Qty 4) M4 x 8.1 Heat set inserts — You should be able to use any length of M4 insert, just make sure to choose the corresponding fastener accordingly.

- (Qty 1) M5 x 9.5 Heat set insert — This will be the load path from the servo to the camshaft, so just make sure you have enough thread engagement, but with it being M5, really any depth of insert should be fine.

- There are a number of options for fasteners, and I tend to just use assorted kits for each size, which is overkill for the few fasteners you’ll need for this. So I’ll list them here

- (Qty 4) m4 x 10 BHCS

- (Qty 1) m5 x 30 BHCS — could also sub this with an m4x30 and replace one of the m5 nuts with an m4 nut, but may want to also toss in a washer just to be safe.

- (Qty 2) m5 x 18 BHCS

- (Qty 3) m5 hex nuts

Assembly

This project is part of a collection of AgTech projects that I am working on putting together as an open source hardware project, JFS Agri. I am excited by the intersection of growing my own food and playing with tech toys :) if you’d like to see a summary of the projects along the way, I’ve started an overview page here. I’d love to find like-minded folks with a similar interest that are interested in collaborating, generating data, or just chatting about AgTech!