Continuing work on the Project Fireplace pepper growing system (aka, the instrumented produce-growing system(s) that will live above the fireplace). I decided the next subsystem to tackle for this build is the frame and structure for the lighting.

The main challenge for this subsystem is the need to be able to raise and lower the lighting components relative to the plant. This is important for both reducing the wasted light, but also for maintaining lighting intensity when plants are in early growth stages.

To be fair, I could kick the can on this problem, and instead try to accomplish this by moving the hydro system to move the plant instead....but as much as I love an opportunity to procastinate, that sounds like a real pain in the ass. So light moving it is.

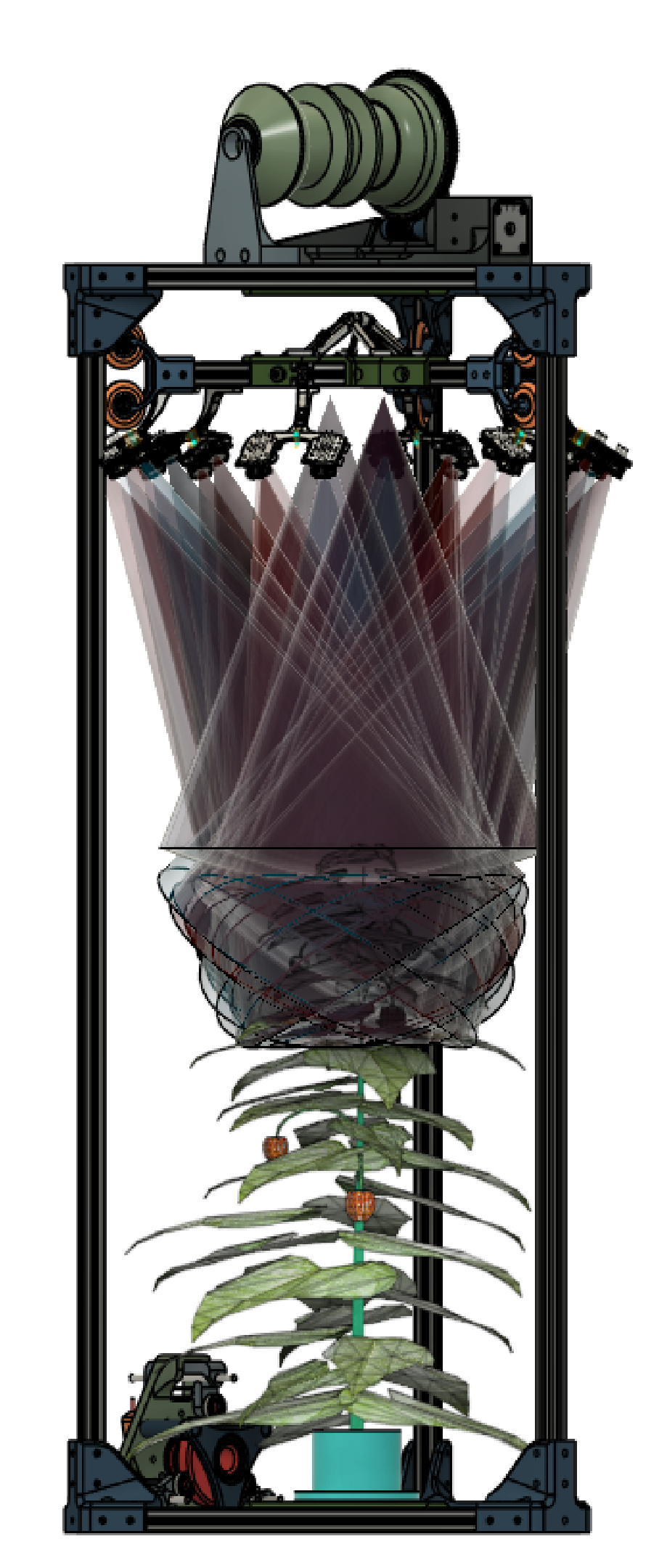

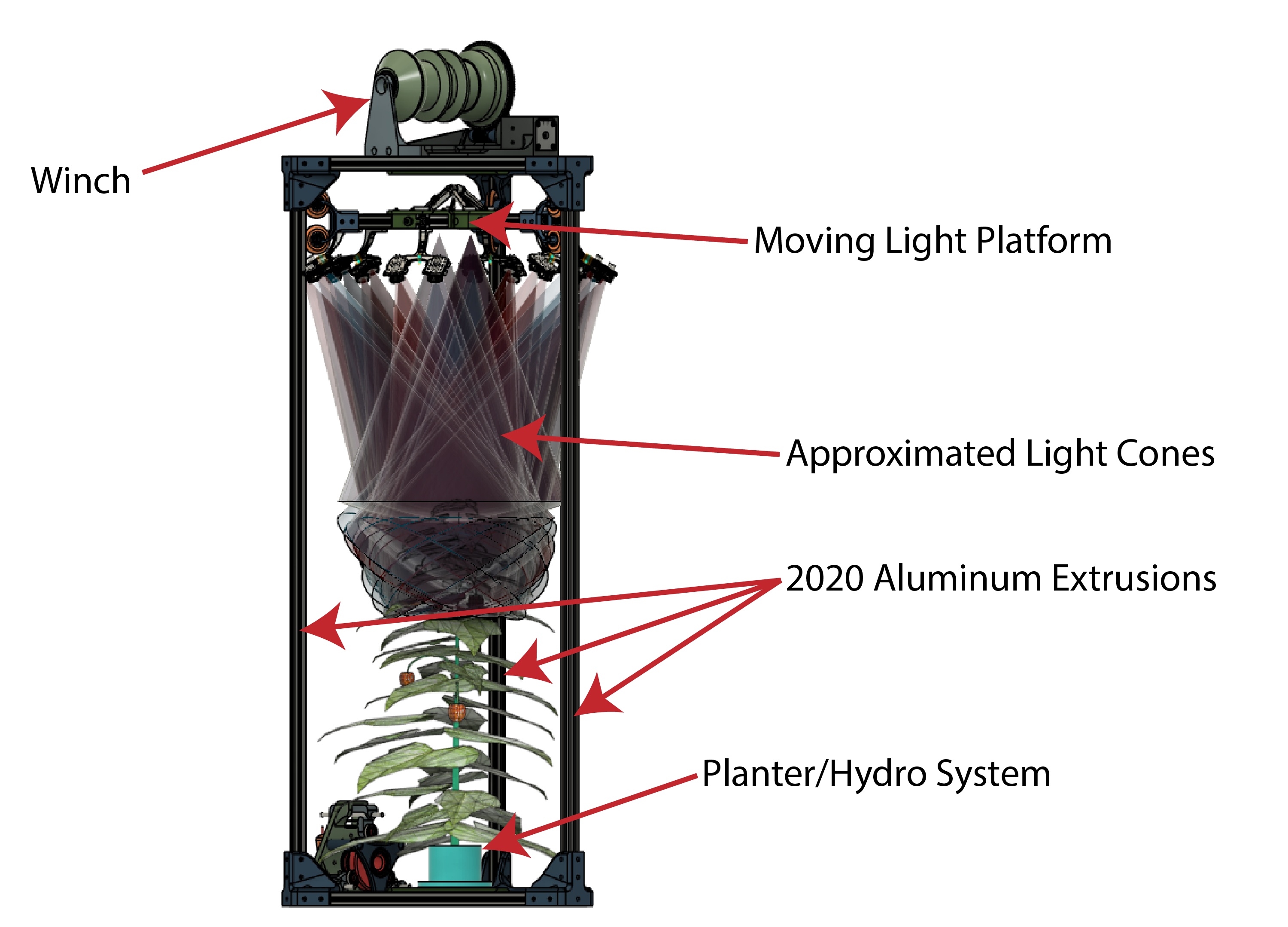

Design Overview

The main structure of the system will be provided by some 2020 aluminum extrusions connected by 3d printed (FDM from PETG) brackets. On top of that structure sits an admittedly oversized winch. The winch raises and lowers the moving platform that the LED clusters will be attached to.

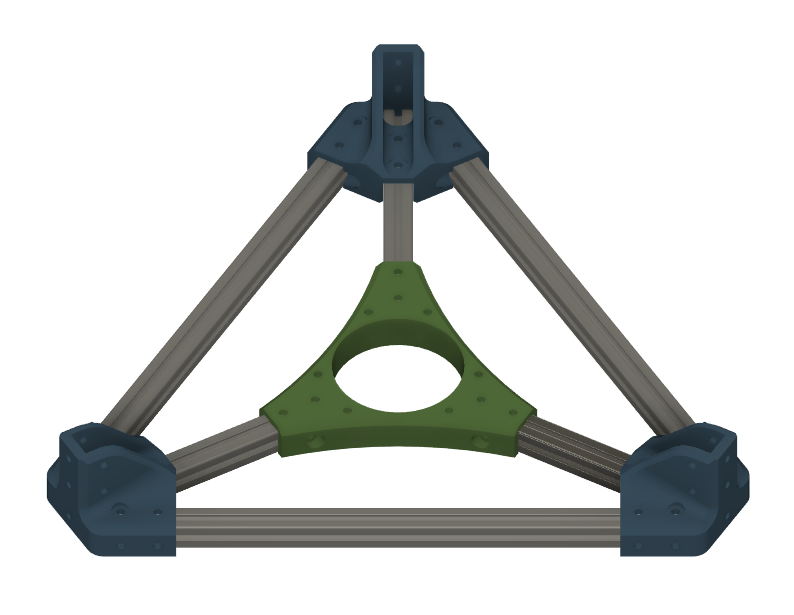

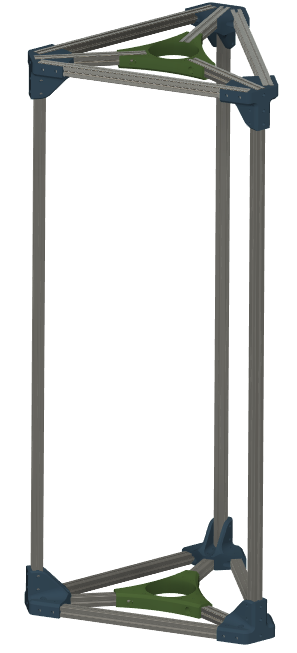

Taking a closer look at each of those, let's start with the base and top frame assemblies. Both are the same construction, shown in the image from the model shown below.

It is made up of 6 pieces of 2020, connected together with four PETG brackets. The brackets in the center provide structure and attach points for 1) the planter/hydro system on the bottom and 2) the lift system on the top. The top and bottom assemblies are connected together with a set of vertical 2020 extrusions. The length of these extrusions sets the total height of the system. I went with 1m lengths.

WORK IN PROGRESS - This article is a work in progress. If there are specific aspects of the project you're eager to know more about, feel free to drop a comment here or on my socials and I'll prioritize getting that part added!