BubsBuilds Projects

- Details

- Parent Category: BubsBuilds Projects

- Category: Printer Stuff

Design Overview

Build

BOM

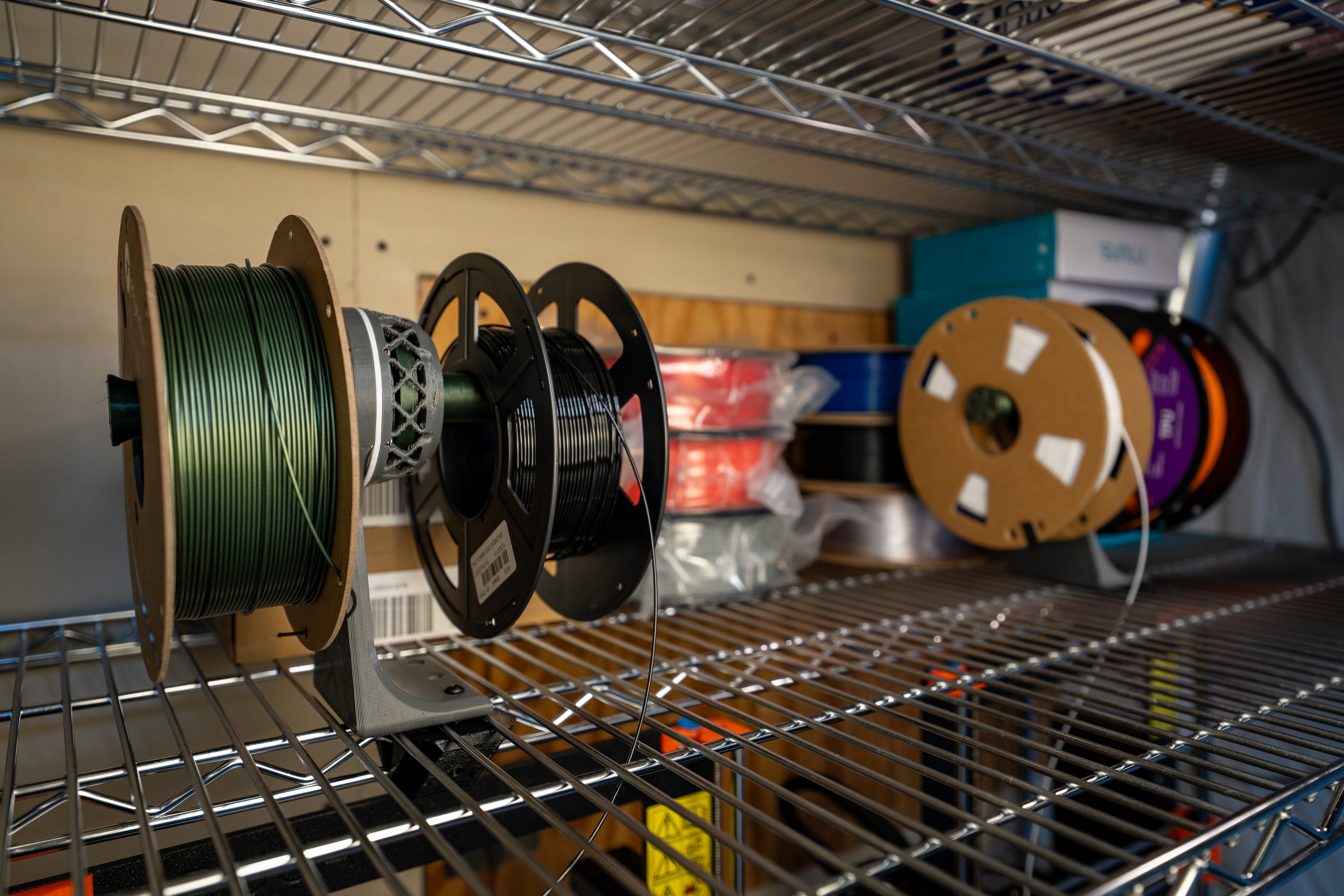

- Printed

- (1) MountRace - Mostly Sunlu PETG, with a touch of green Polymaker PETG on the base

- (1) RetainerRace - White Sunlu PETG

- (1) Cap - Black Sunlu PETG

- (1 or 2) SpoolPost - Green Polymaker PETG

- (0 or 1) SpoolBlank - Only needed if using for a single spool. Shown in the gif above. Green Polymaker PETG

- (?) Spacers - The number and thickness of spacers depends on how much preload you want to put in your bearing.

- COTS

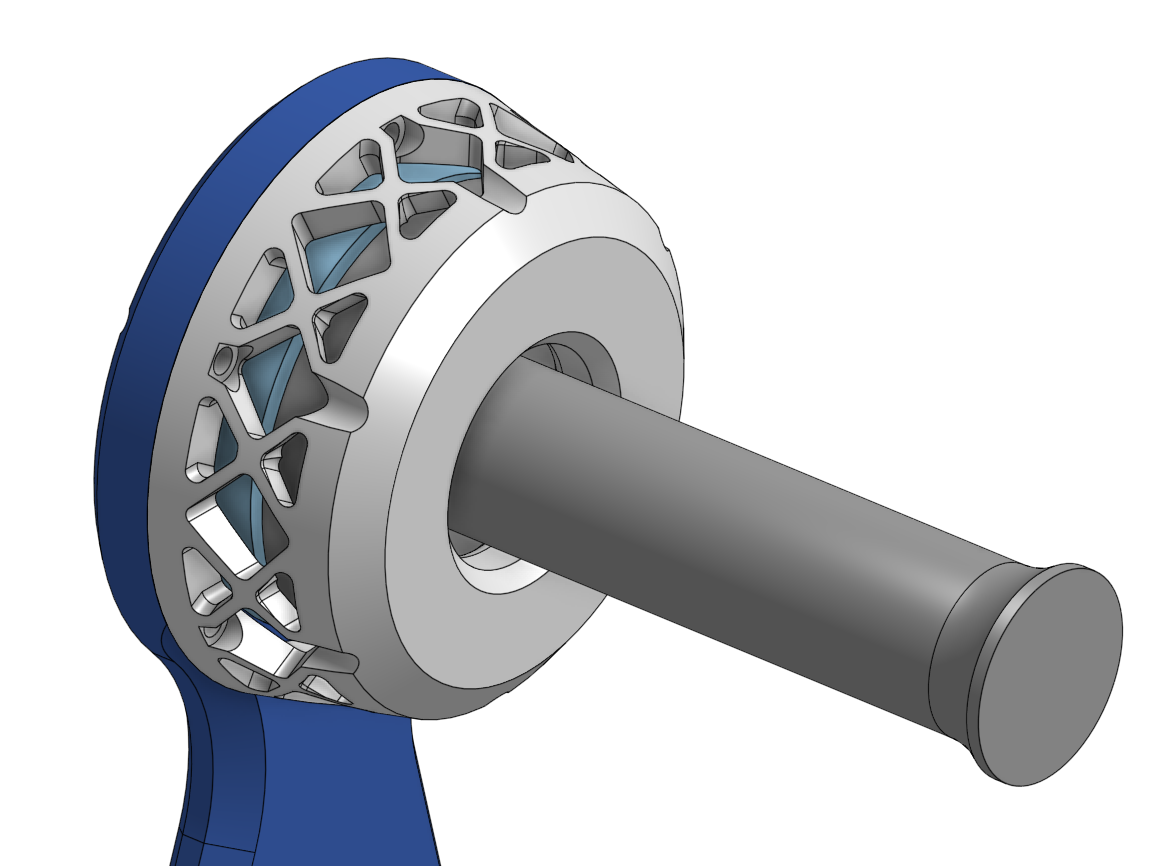

- (33) 9.5mm balls - 16 in each race and one for the center 'jewel bearing'. I actually use 3/8" 'slingshot ammo', but it's technically modeled for 9.5mm...close enough :)

- (6) M3 heat set insert - I went with 6mm lengths. Anything up to 10 should be fine.

- (6) M3 BHCS - Length will depend on spacers, but likely between 10 and 12 mm lengths should work.

- (2) M5 heat set inserts - For the Cap

- Insert six M3 heat sets in Mount Race

- Insert two M5 heat sets in Cap

- TIP: if you're planning to set it up for two spools, I'd recommend setting the Mount Race up in a vise or the like with the bearing race aiming up. This will make the next steps much easier.

- Drop in the 16 balls in the Mount race.

- Set the Spool Blank or Spool Post onto the Mount Race so that the bearing races nest. It should spin pretty freely. If it doesn't, now's a good time to check for any print blobs or the like that might be getting in the way.

- Place a single ball into the cone on the back side of the Spool Post (or Blank)

- Set the other Spool Blank on top...like a little top hat...

- Add the remaining 16 balls to the race of the Spool Blank.

- Slide the Retainer Race over the post of the top Spool Post and into position. Be careful to not knock over the post to avoid playing 16 ball pickup. Also, I found it easier to insert the fasteners in their holes before lowering the retainer onto the assembly.

- Tighten the retainer fasteners, preferably using a star pattern to close the bearing evenly. You want to tighten these fully (I don't have a torque spec for ya, but 'fully tightened for M3 in polymer...?). If the bearing feels too tight for your liking, you can add in one or more of the Spacers to get your preferred level of preload or play.

some Design Notes

2024/01/16 - Initial Design

- Details

- Parent Category: BubsBuilds Projects

- Category: Printer Stuff

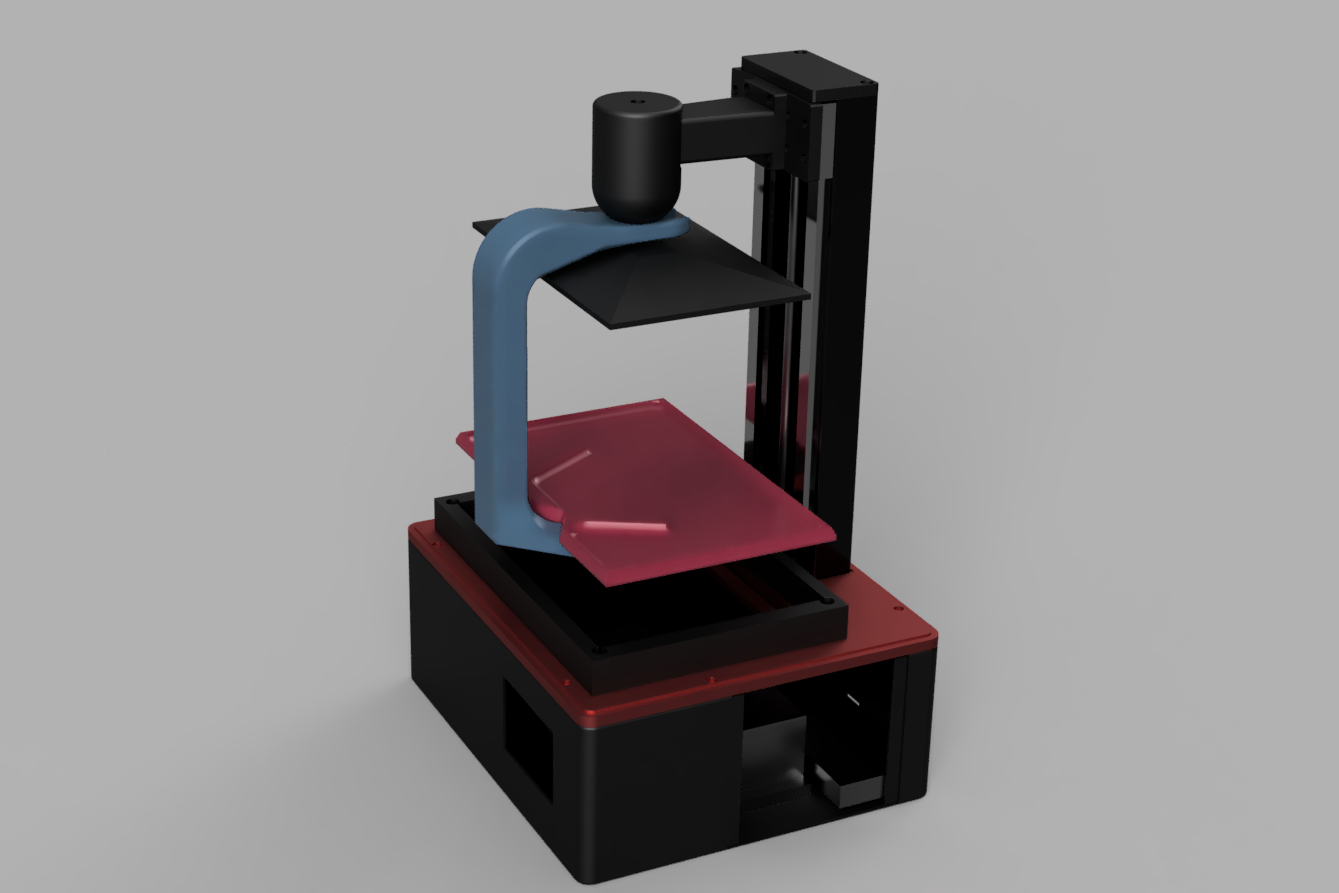

One of my more consistent ways to make me curse my own name is when I dump resin down the front of a printer while removing the platen...I just got sad thinking about it. I've also found, on more than one occasion looking for a stable place to put a loaded platen while I scramble for whatever thing I've forgotten. So I decided to build something that could save me from myself on both of these.

|

|

The Drip tray is preloaded against the Hanger using some magic blocks (aka magnets). I used two of these 60x10x5 magnets in the base of the Hanger and these 60x10x3 magnets in the Drip Tray. If you're looking to simplify on parts, I'd recommend using the thinner, 60x10x3, in both locations as opposed to the alternative. As I have mine, it is a quite strong preload (but that is what I was aimin for!) If you were to go with 60x10x5s on both ends, it will also be possible for the magnets to make contact...which may not end well, those neodynium magnets are pretty brittle.

I printed mine from Clear and White Overture PETG. I LOVE the clear, but I don't know why I ever buy white filament...not ma favorite

- Details

- Parent Category: BubsBuilds Projects

- Category: Printer Stuff

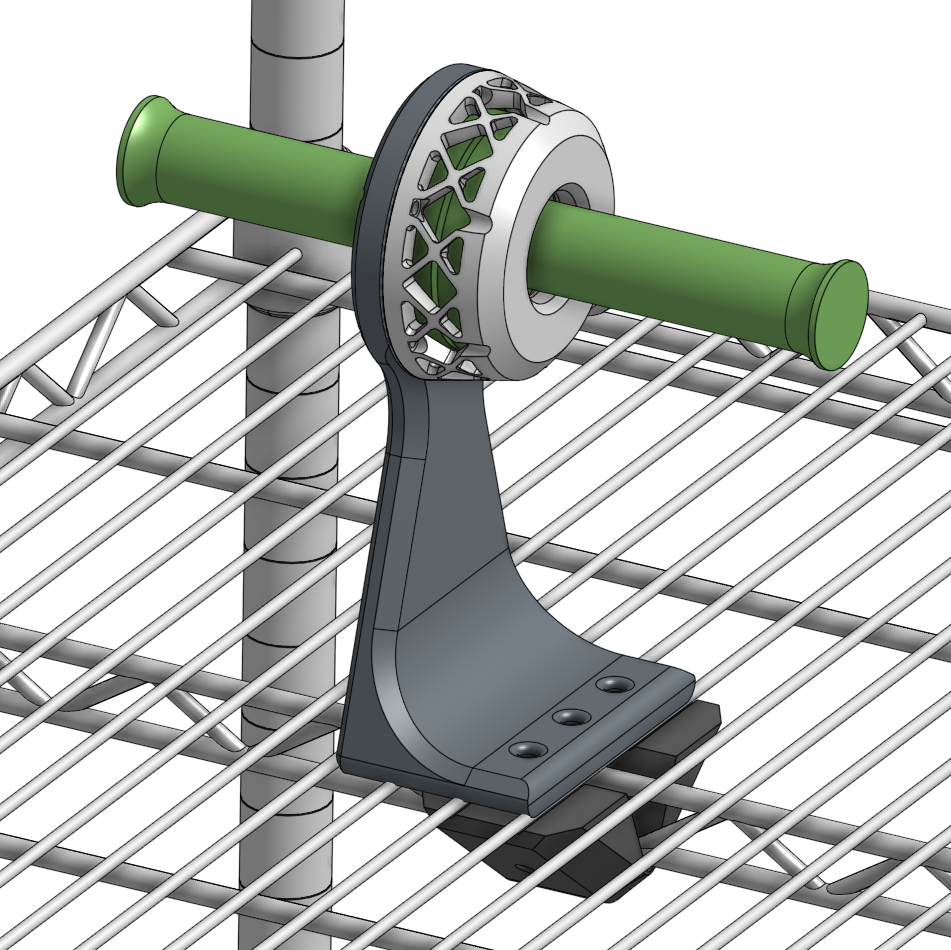

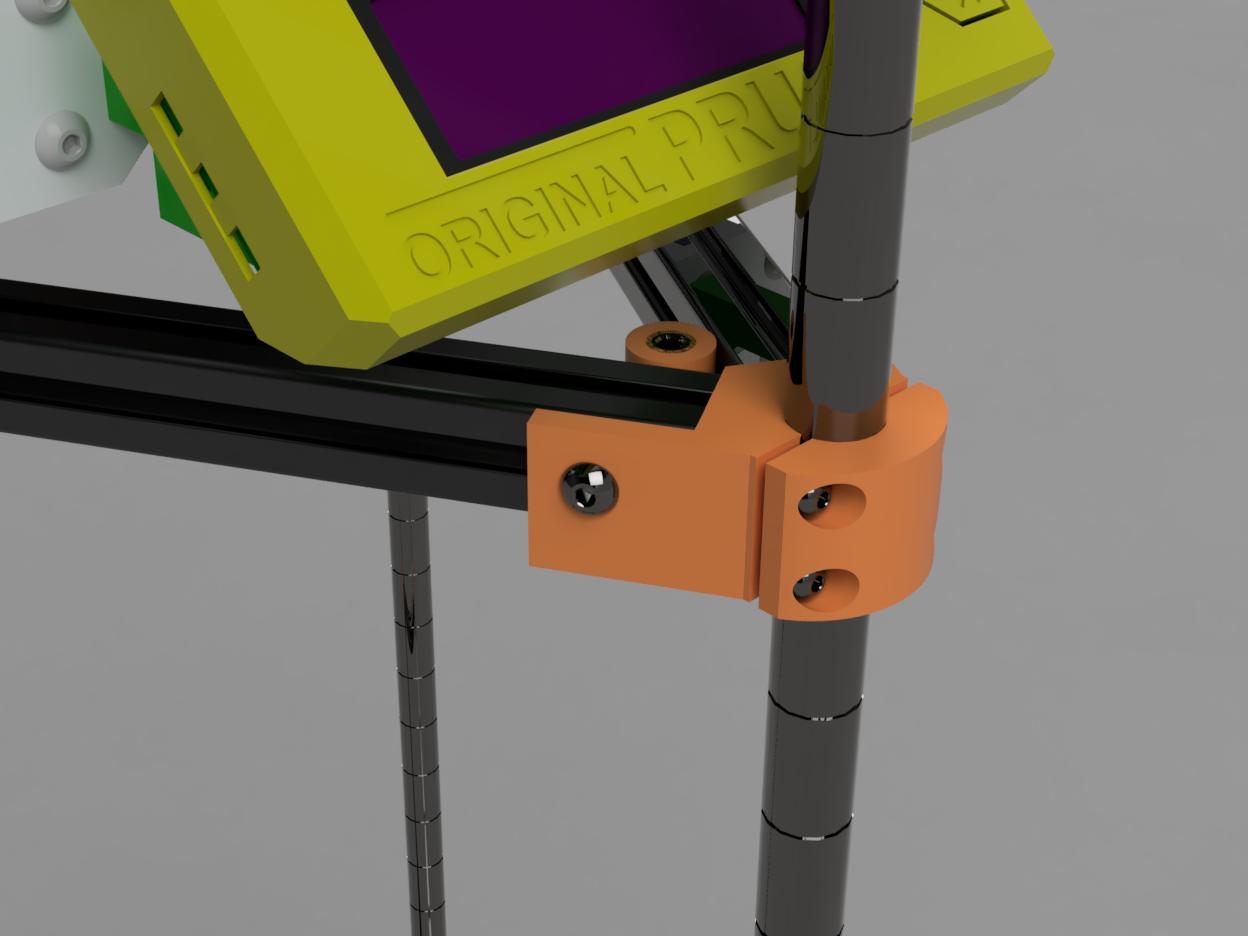

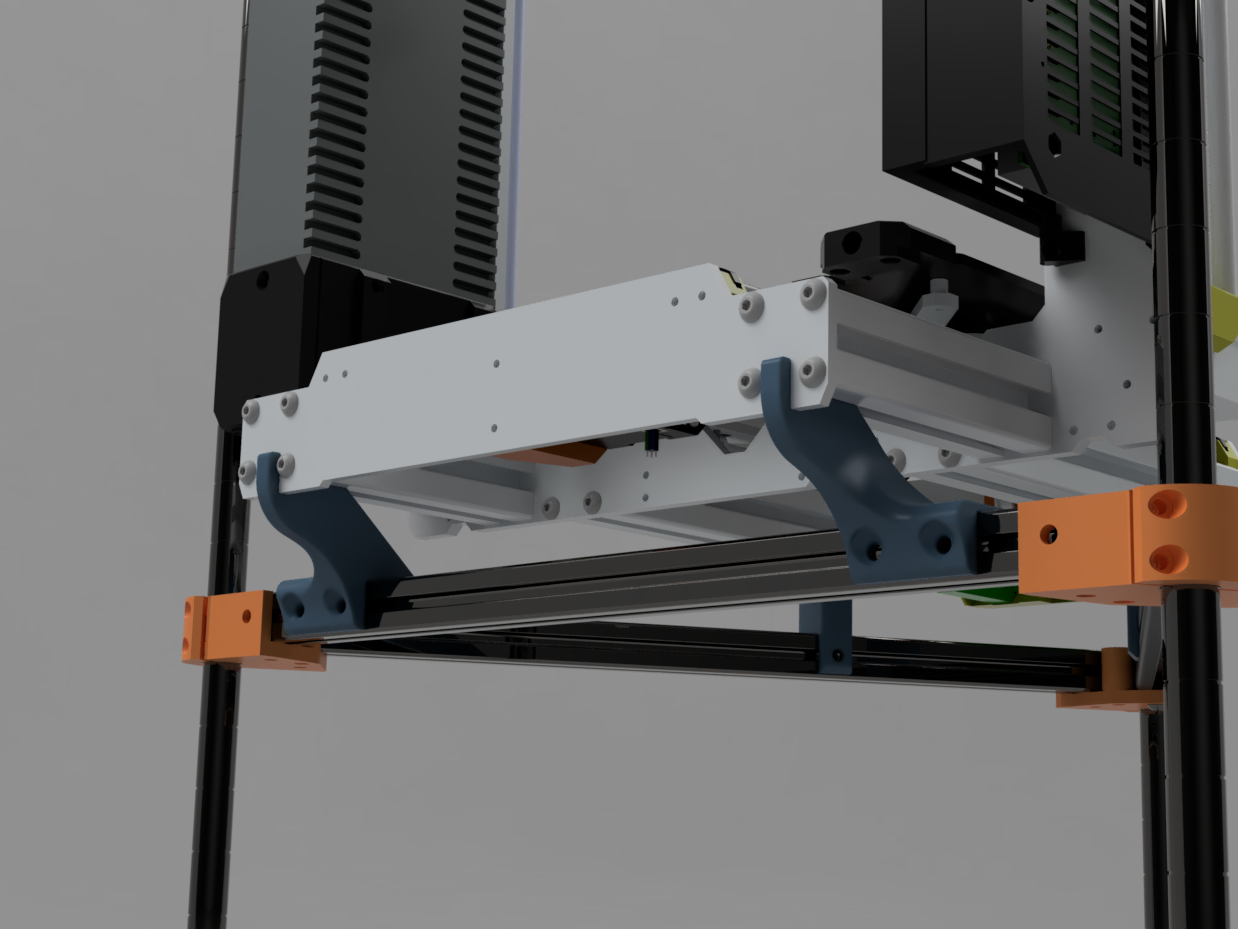

i3 Printer Stand

I made these with the intention of them being something I can easily extend/update/modify over time. The upright posts are 16mm diameter wire shelving posts from these shelves (I'm planning to use the wire shelves themselves as a trellis for a different project :) ) and the cross-members are made from 400mm lengths of 2020 extrusions. I chose both of these because the former is well-suited to clamps for things like cameras, sensors, etc. and the 2020 extrusion is just generally good for modular projects.

I have now printed about a dozen parts on each of the printers pictured (and yes, I still have yet to populate the center level of extrusions...seems fine for now ¯\_(ツ)_/¯

They definitely have some compliance to them, but only in modes that thus far don't concern me (mainly some torsional compliance up along the central axis of the stand). I also expect quite a bit of stiffening as I add things like a dry box to the middle tier. I suspect I may have to add some squish back into the printer mounts sometime in the future to keep the printer isolated, but for now I'm actually pretty pleased with how the tower itself is acting as an isolator between the printer and ground.

BOM

- Upright Posts - I used three of the post assemblies from this wire shelving unit.

- "Levels"

- (Qty 3/level) Clamps

- ClampBody.stl and ClampCap.stl - I printed mine from Orange and Black Overture PETG and from this Matte Navy PLA (which I really like the look of, but I don't generally like making long term structural parts from PLA)

- (Qty 4/clamp) m5x10 bhcs and their t-nuts

- (Qty 4/clamp) m4x16 bhcs and their heat sets

- Optional - m5 heat set

- (Qty3/level) 20mmx20mm Aluminum t-slot extrusion - 400mm length

- (Qty 3/level) Clamps

- Printer supports

- (Qty2) Support_Front.stl

- (Qty1) Support_RearL.stl

- (Qty1) Support_RearR.stl

- Printer....

Printed part files:

Corner Clamps

|

|

Each level of the stand uses three of these printed brackets, and three sections of extrusion. I went with 400mm extrusions for these two stands for my Mk3s printers.

The brackets are secured to the extrusion with two m5x10 fasteners on each extrusion. The end cap is secured to the bracket with four m4x16 fasteners in companion heat sets. There is also an additional m5 heat set in between the extrusions, but it is only there as a "might be handy in the future" feature. So up to you as to whether to populate it.

|

|

Printer Supports

|

|

The supports are currently a little over-constrained, but leaving them unfastened from the extrusion has worked fine for me so far.

The rear supports are intended to sit inside of the t-slot extrusion of the i3, and then also behind the cast plate on the back of the printer.

The front supports are just cylindrical posts that sit inside of the front extrusions.

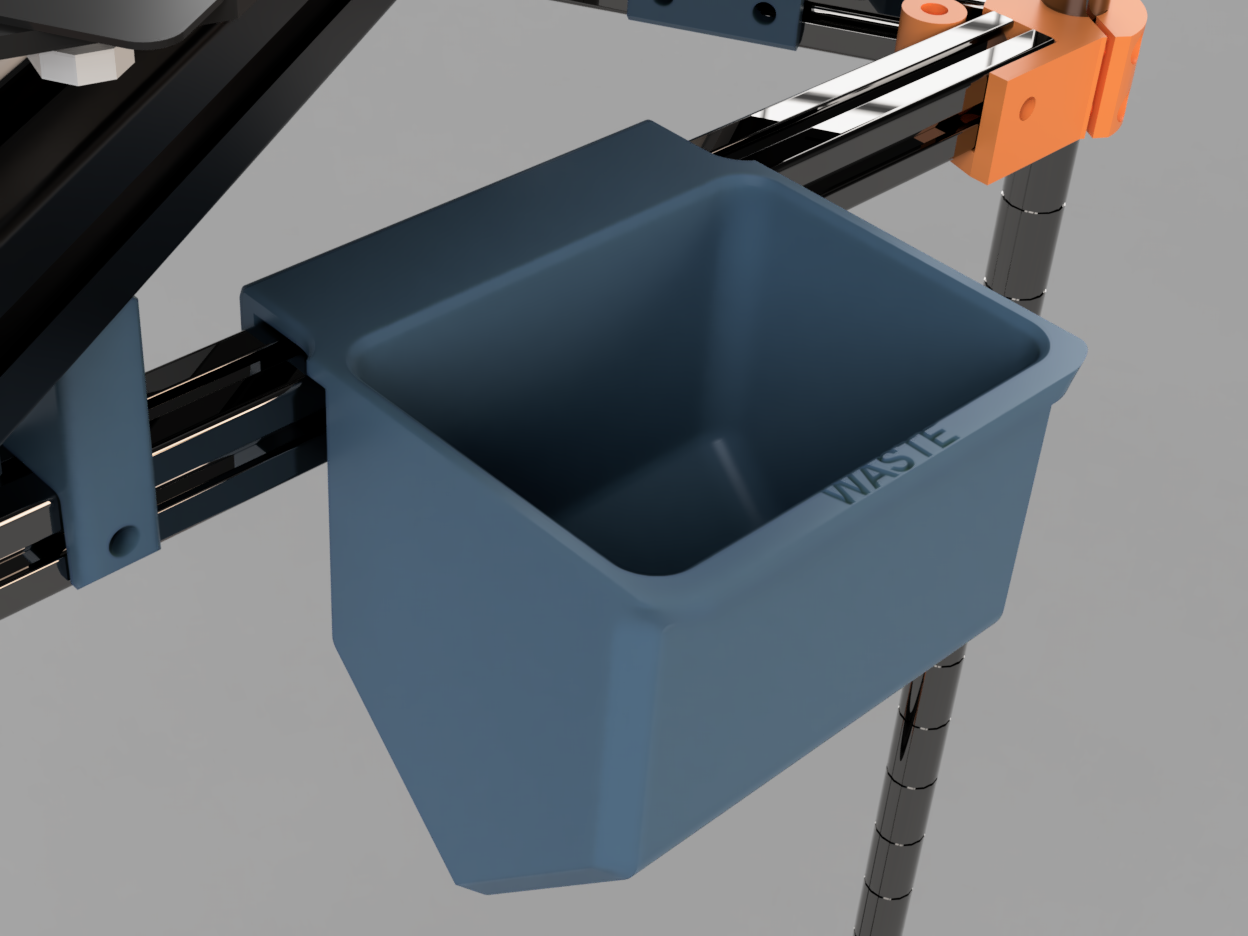

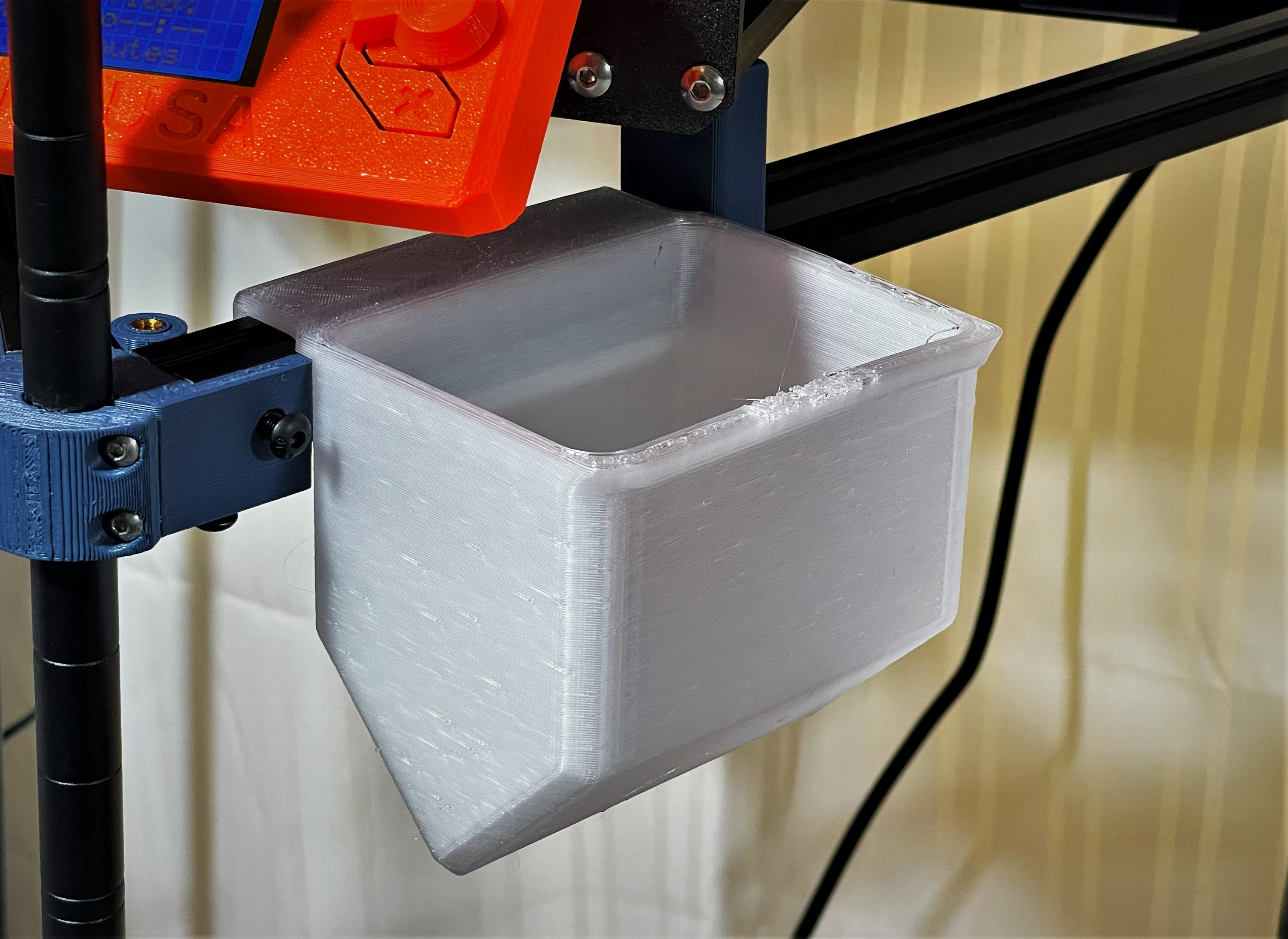

Waste Bin

|

|

A simple waste bin that hangs from 2020 extrusion, intended as a convenient spot for tossing purge lines, brims, and the other assorted scraps/trash that accompany extrusion printing.

Prints without supports and took about 3.5 hours with the attached slicer config (0.6 nozzle), but I should point out that the lettering on my print came outa little lackluster.

I printed mine in Overture clear PETG

Simple Hook

A simple, quick-printing hook for hanging accessories and such from 2020 extrusions. I'm using several of them quite happily on my i3 printer tower.

Subcategories

Assorted (hopefully) "Useful Stuff" Projects Article Count: 12

Like the bucket of assorted fasteners on that bottom shelf, this category is for stuff that I didn't know how to group...oh, and speaking of those fasteners, check out the little sortin fella!

2020 Aluminum Extrusion Hardware

|

Quick Bolt Sorter

|

General Purpose Turntable - Gen1

Games Article Count: 1

Generative Design Projects Article Count: 3

During the good financial decision-making times of Covid lockdowns, etc. I decided it was a good idea to buy a license for the Fusion360 Generative Design extension...Good news, I did finally pay that off :) I had worked around, and been somewhat involved in a handful of Topology Optimization/Generative Design projects through my work, and I've found the tech super interesting for some time. So after the free trial, and feeling like I was just starting to gain some level of competence in Fusion360's tool....I done did it, and bought the year. Ok, now that I'm done justifying that to myself...I mean you...

<engineering/design> What I really like about Generative Design is that it forces the designer to think about the thing they are trying to design from it's core requirements: Forces, Interfaces, and Keep Outs. I think it's far from perfect, especially given the still very primitive Design For Manufacture capabilities these tools have (among other shortcomings, but this one is certainly a big one to me.)

<precision engineering> One last also (for now), but ALSO, what I find exciting about these tools from a precision engineering perspective, is that the above-mentioned focus on forces and interfaces, these tools are extremely well-suited to kinematic/exact constraint designs! I think every one of the Generative Design projects below features at least some aspects of kinematic constraint (I say, "I think" because I may or may not be writing this before I go through my files and remind myself what all I actually made vs what I just thought about making ¯\_(ツ)_/¯ )

JFS Projects Article Count: 14

AgTech (aka finding a way to complicate and digitize gardening) Projects Article Count: 12

Hydration and Hydroponics Projects Article Count: 8

Peristaltic Pumpin Article Count: 4

A lot of projects I work on/have worked on seem to involve the controlled movement of fluids. Below is a bit of a history of my builds involving attempts at obtaining this controlled movement for incompressible fluids. I haven’t done much myself with making custom solutions for the compressible stuff, but if you’re interested in such things, I thoroughly enjoy Major Hardware’s “Fan Showdown” series :)

This article/section is by no means intended as a thorough overview on the design and operation of pumps. While I will try to give some overview on operating principles and design considerations as I go, this is mainly just going to be a wander through my personal builds and experiences.

Peristaltic Pumps

What is a peristaltic pump?

I’m sure there are innumerable sources online for (much better) detailed discussions of the workings of peristaltic pumps. So I’m just going to hit the highlights, and I’ll try to remember to find some promising links and add them below, should a deep dive seem intriguing to ya.

Basic Operation:

The fluid being pumped is carried into the pump in a compliant tubing. This tube is routed around some portion of a circular/cylindrical path around the axis of the pump and then exits the pump. This is one interesting/attractive aspect of peristaltic pumps, the fluid never has to leave the tube that it is in, making these pumps well-suited to situations where contamination and/or leaks are highly undesirable. The housing that features the cylindrical wall that the tubing is being routed along can be considered the Stator, and that is generally the nomenclature that I tend to use.

So if there’s a Stator, there must be a Rotor…? Yup, the rotor includes some set of features that extend out to some defined gap between this feature and the Stator wall. These features, which in many peristaltic pumps are rolling element bearings, pinch the tubing to the point of sealing (ideally) the tube. As the rotor turns, this contact point proceeds around the circumference. Because the pinched point of the tube is sealed, the volume of fluid in the tube ‘ahead’ of the pinch point are, as a result, pushed forward. So, keep rotating, keep pushing….pretty much as simple as that!

Pros:

- Positive Displacement Pump

- Because the pinch point is (ideally) fully sealing the tubing, the amount of fluid moved is directly proportional to the movement of the pump. This makes them very good choices for things like dosing pumps or other applications where the desired volume of fluid to be moved needs to be deterministic.

- This is a large driver for my initial interest in using peristaltic pumps. Their deterministic flow is/was very attractive for my plant growth experiments. They can give very repeatable watering volumes and nutrient concentrations.

- Fluid Isolation

- Because the fluid never leaves the tubing, these pumps can be suitable for moving hazardous materials. For example, I have been using a peristaltic pump for transferring 99% IPA

- Relatively Simple Construction

- Because the fluid does not have to be sealed within the pump, these pumps lend themselves well to DIY builds. No shaft seals, gaskets, etc. or complex (at least to do well) impeller design needed.

- Self-priming and Head height

- If well-sealed, these pumps are capable of self-priming (and even pumping air) and of achieving pretty impressive head heights (the measure of how high above the pump it can pump a column of water)

Cons:

- High drive torque

- Because of the preloading needed against the tubing, and the rolling friction, even with good rolling elements (more below on this), it can be quite easy to end up with designs that require quite a lot of drive toque.

- Tubing wear

- With the relatively large deformation and high number of cycles, the tubing will eventually fail, either due to material wear, fatigue cracking, or who knows what else. Because this failure mode can cause fluids leaking into your pump not designed to experience this fluid, this failure can potentially be quite problematic. So the use of high-quality tubing material and a plan for periodic maintenance, are worthwhile.

Test Build 1

A couple of years back, I had a concept for an in-line-mixing hydroponics system. The idea being that the supplies to the system would be just pure water and nutrient concentrates, and a series of pumps and valves would allow precise dosing mixes to each target plant in a system (I refer to this concept as Rail Yard Hydro, since it moves the fluids around the tubing network quite like rail cars are moved around a rail system. I’m planning to add a separate page diving into that one a bit deeper since it is the design scheme I am using in my current projects.)

Well, to facilitate this plan, I wanted to find an option for a dosing pump that I could integrate in to my control system (aka Arduinos and Raspberry Pi’s :)). Unfortunately, I quickly found that a servo-driven peristaltic pump could easily set me back north of $100….so I set out to spend many multiples of that making my own!

Actually, when I saw the pricing, I decided I should see if I could make myself a cheapo, manual version that I could use to just test out some basic questions on the Rail Hydro idea (mainly verifying that I could induce good material mixing in-line and that there was no cross-contamination between fluid reservoirs.) And so, ‘twas this endeavor that resulted in the pump I’m apparently referring to as “Test Build 1”

Design Objectives:

- Be a peristaltic pump

- Provide a full seal (at 100mm head)

- Be hand-cranked

- Not require any parts that would have to be ordered (I’m impatient)

The Build

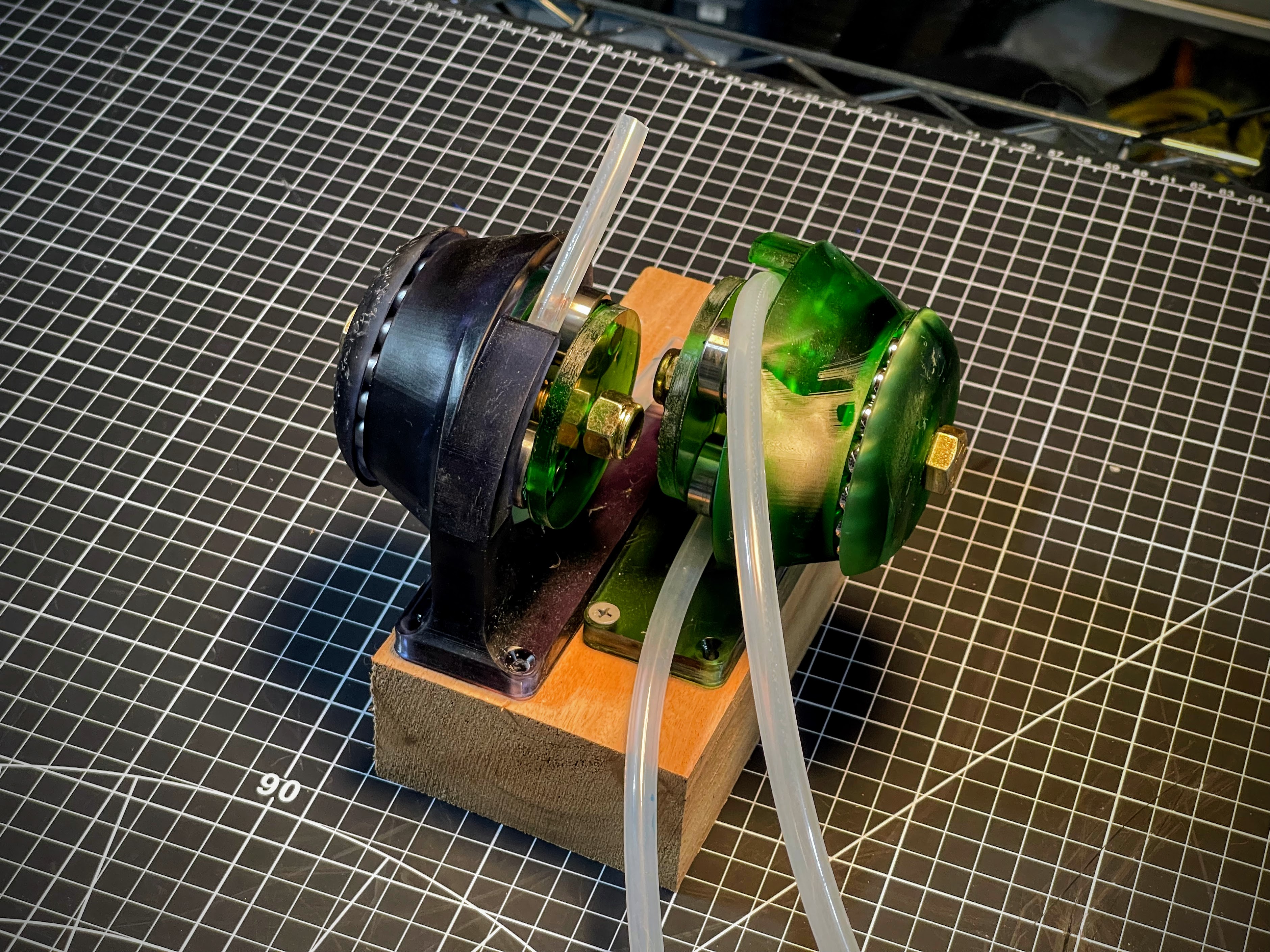

She ain't pretty (especially after a good while of getting knocked around), but the pic above shows the dual pump setup I rigged up for my testing needs. I was VERY pleasantly surprised that, other than a tweak to the hand wheel, these things worked pretty damn well!

I decided upfront that I was going to go with a resin printed build, because I thought the high stiffness and good surface finish throughout the 'pinch region' would give me a better chance. Since I was already going to have the good surface roughness, I might as well also integrate the main bearing into the printed parts.

In the image of the model, below, the Stator is the part shown in green, and the Rotor is shown in blue(ish.) Riding on the rotor are roller skate bearings to provide the contact with the tube. Race 1 has v-grooves on both sides of the race, providing the main constraint for locating the rotor, and Race 2 has a v-groove on the Stator, but only a single plane of contact on the Rotor side. This keeps from over-constraining the bearing.

|

|

The absurdly overkill bolt running through the center is a real showcase of "using what I had on hand" :) in that these were the only bolt/nut sets I had on hand with the length I was looking for.